Burner combustion method

A combustion method and technology of a combustion device, which are applied in the field of burner combustion, can solve problems such as reduction and lack of practical value, and achieve the effect of reducing NOX

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0055]

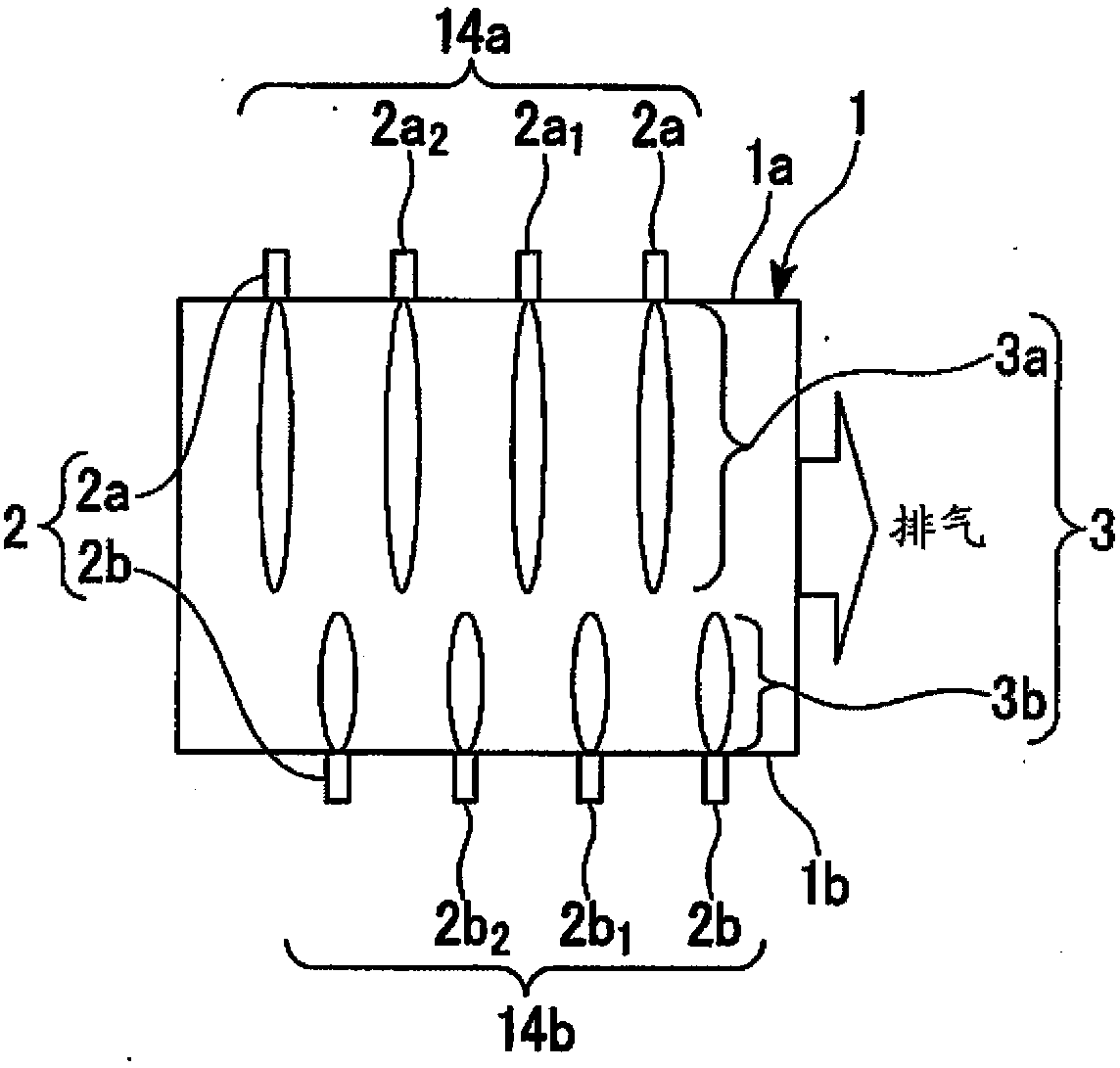

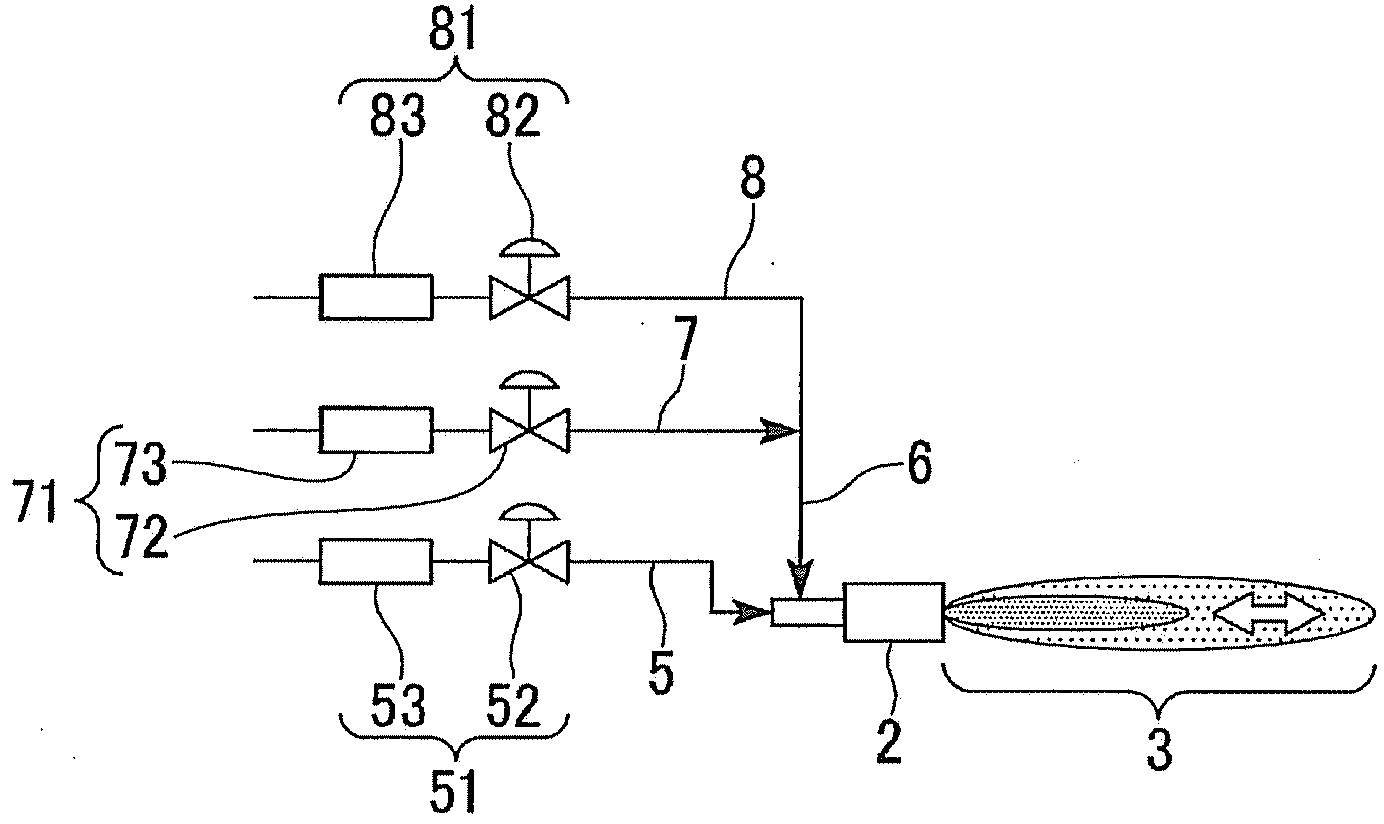

[0056] The combustion apparatus used in the first embodiment of the present invention such as figure 1 with figure 2 Shown is a structure including a furnace 1 , a burner 2 forming a combustion flame 3 in the furnace 1 , and various pipes 5 , 6 , 7 , and 8 for supplying a fuel fluid and an oxidant fluid to the burner 2 .

[0057] Such as figure 1 As shown, the furnace 1 may be a heating furnace or a melting furnace, and includes a side wall 1 a and a side wall 1 b extending in the longitudinal direction and arranged to face each other. A plurality of burners 2a are provided on the side wall 1a, and a plurality of burners 2b are also provided on the side wall 1b. Thus, the furnace 1 has a so-called side burner type structure in which burners 2a, 2b forming combustion flames 3a, 3b are provided on both side walls 1a, 1b in the longitudinal direction.

[0058] In addition, in the present embodiment, the number of burners 2a provided on the side wall 1a is the same as...

no. 2 approach

[0109] Next, a combustion method using the burner according to the second embodiment of the present invention will be described. In addition, this embodiment is a modified example of the first embodiment, and description of the same parts will be omitted.

[0110] This embodiment differs from the first embodiment in that a phase difference is provided in the pulsation cycle of adjacent burners 2 , and the others are the same as the first embodiment.

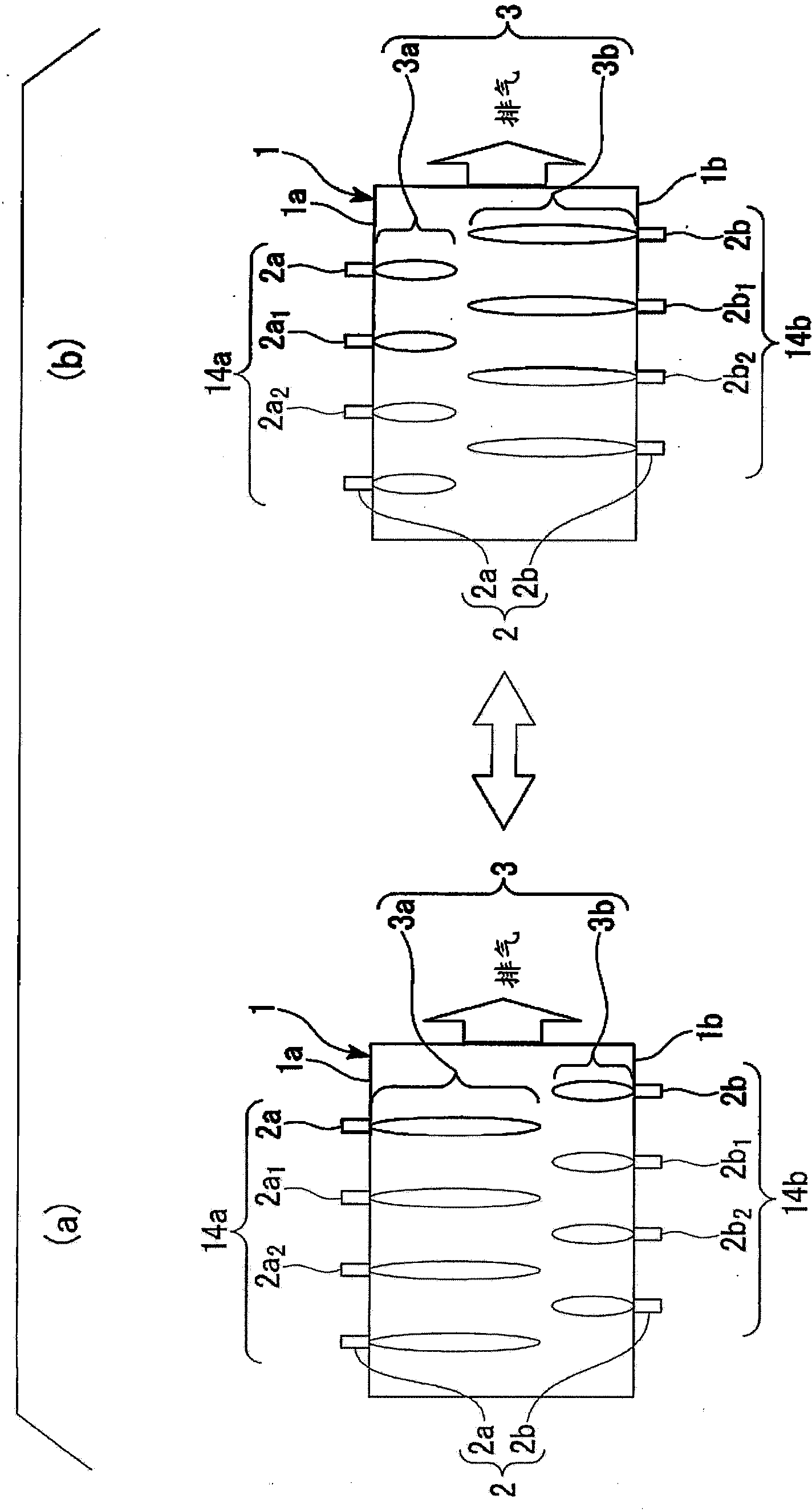

[0111] Such as Figure 4 (a) and Figure 4 As shown in (b), in this embodiment, a plurality of burners 2a and 2b are respectively provided on the side wall 1a and the side wall 1b. Only one burner 2 forms each burner array 24 . That is, each burner 2a provided on the side wall 1a forms a burner array 24a, and each burner 2b provided on the side wall 1b forms a burner array 24b, respectively.

[0112] In addition, in this embodiment, adjacent burners 2 are controlled so that the phase difference of the pulsation period is π. ...

no. 3 approach

[0119] Next, a combustion method using the burner according to the third embodiment of the present invention will be described. In addition, this embodiment is a modified example of the first embodiment, and description of the same parts will be omitted.

[0120] This embodiment differs from the first embodiment in that a difference is provided in the pulsation cycle of adjacent burners 2 , and the rest is the same as the first embodiment.

[0121] That is, if Image 6 As shown, in this embodiment, n burners 2a and 2b are respectively provided on the side wall 1a and the side wall 1b of the furnace 1 . Only one burner 2 forms each burner array 44 . That is, each burner 2a provided on the side wall 1a forms a burner array 44a, and each burner 2b provided on the side wall 1b forms a burner array 44b.

[0122] In addition, in this embodiment, it controls so that the phase difference with the pulsation period of the adjacent burner 2 may become 2π / n. For example, in the case w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com