Combustion method that can effectively reduce boiler furnace slagging

A boiler furnace and combustion method technology, which is applied to the combustion method, the combustion using lump fuel and powder fuel, and the combustion type, etc., can solve the problems of the deterioration of slagging of the water wall of the boiler furnace, the aggravation of high temperature corrosion of the water wall, and the decrease of the melting point, etc. , to achieve the effect of avoiding slagging and high temperature corrosion, preventing slagging and high temperature corrosion, and reducing the radius of the combustion flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

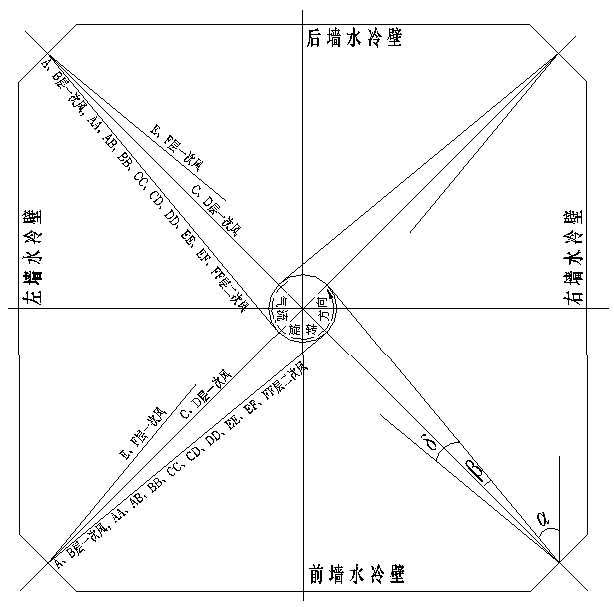

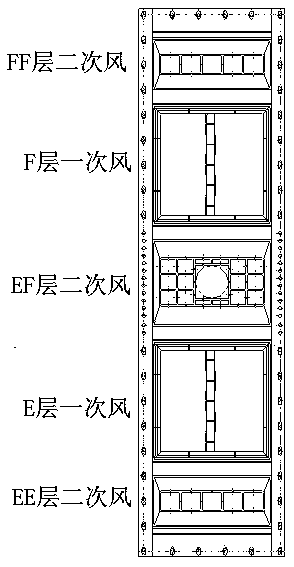

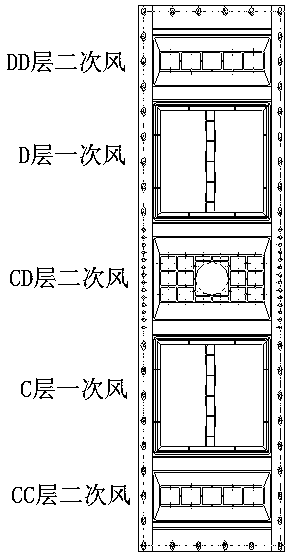

[0026] A combustion method capable of effectively reducing boiler furnace slagging, which comprises: a main burner, the main burner includes a group of primary air nozzles and secondary air nozzles arranged at intervals, and the primary air nozzles are selected at a level Thick and thin nozzles, the rotation direction of the secondary air nozzle is parallel to the central axis of the burner, and the ejected air flow is parallel to the central axis of the burner;

[0027] The combustion method that can effectively reduce boiler furnace slagging includes the following steps: firstly, the main burner is installed on the four corners of the boiler furnace, and the central axis of the corner burner forms a clamp with the water-cooled wall of the furnace. Angle α, α ranges from 40° to 43°, forming a small imaginary tangential circle, effectively avoiding slagging and high-temperature corrosion on the water wall;

[0028] The horizontal thick and thin coal concentrator divides the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com