Detection device of printed circuit board

A technology for printed circuit boards and inspection devices, applied to measuring devices, material analysis through optical means, instruments, etc., can solve the problem of not being able to detect edge shapes smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

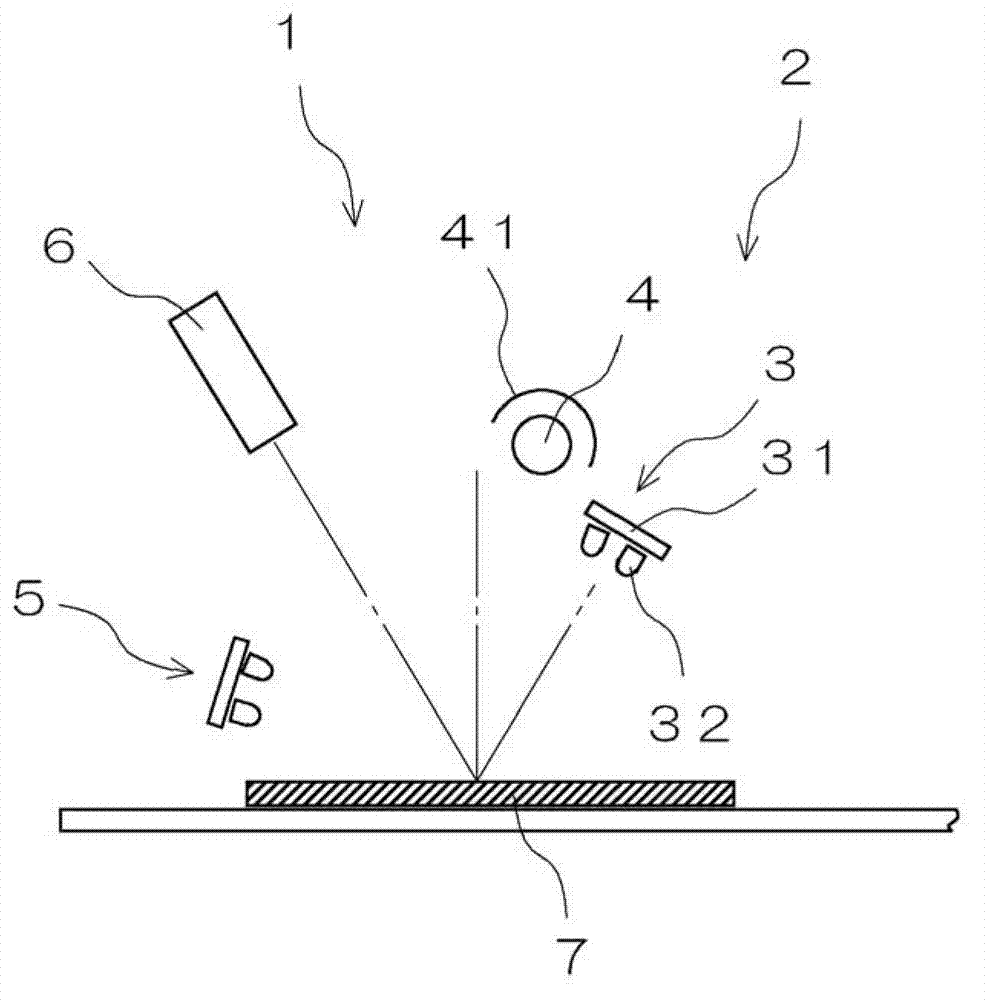

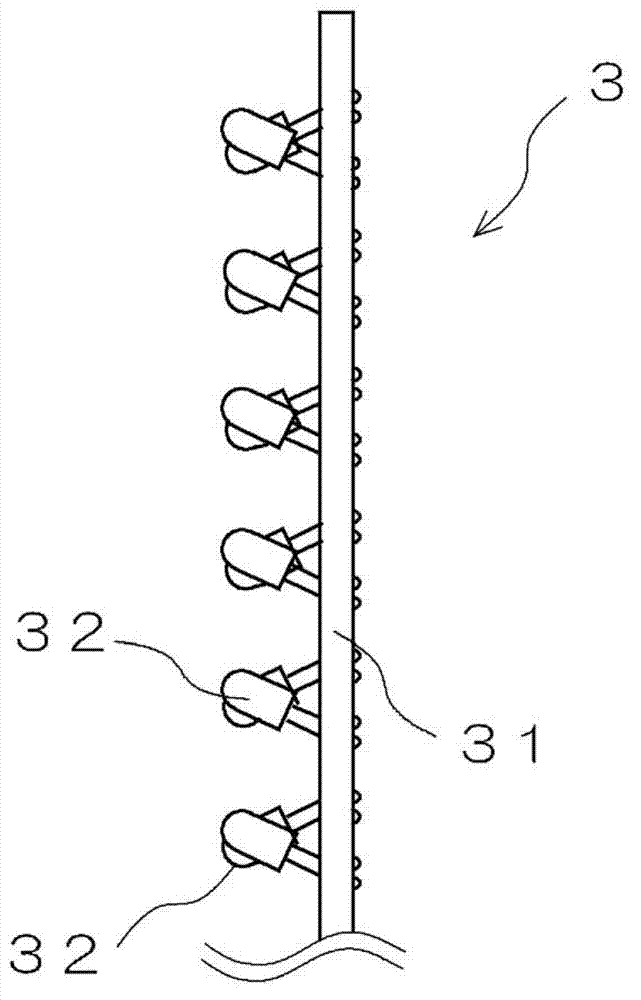

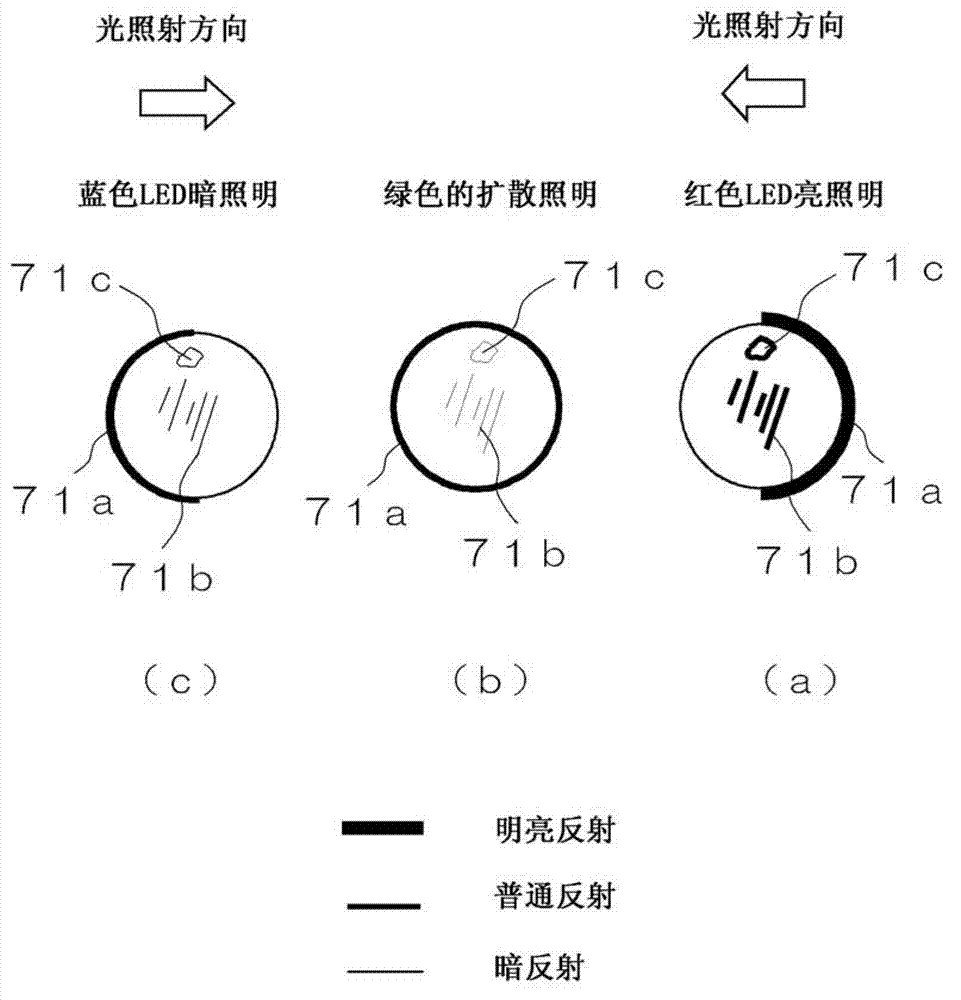

[0032] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. The inspection device 1 for a printed circuit board 7 of this embodiment is configured to include: an illuminating device 2 that irradiates light to a printed circuit board 7 placed on a table; The camera 6 of reflected light; the first inspection unit 81 to the third inspection unit 83 for inspecting the formation state of the pad 71, the resist 72, etc. formed on the surface of the printed circuit board 7 based on the image obtained by the camera 6 (refer to Image 6 )Wait. Furthermore, the lighting device 2 is characterized in that it includes a first color light source 3 including a red LED 32 disposed at a first angle of regular reflection with respect to the optical axis of the camera 6 (that is, at an angle for bright field illumination). ; be configured as a green fluorescent lamp at an angle different from the first angle, that is, a second color light source...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com