A kind of fiber grating current sensor based on refrigeration sheet and its detection method

A technology of current sensor and optical fiber grating, which is applied in the field of detection current and optical fiber grating current sensor, to achieve the effect of increasing the applicable environmental range, improving safety, and avoiding wrong information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

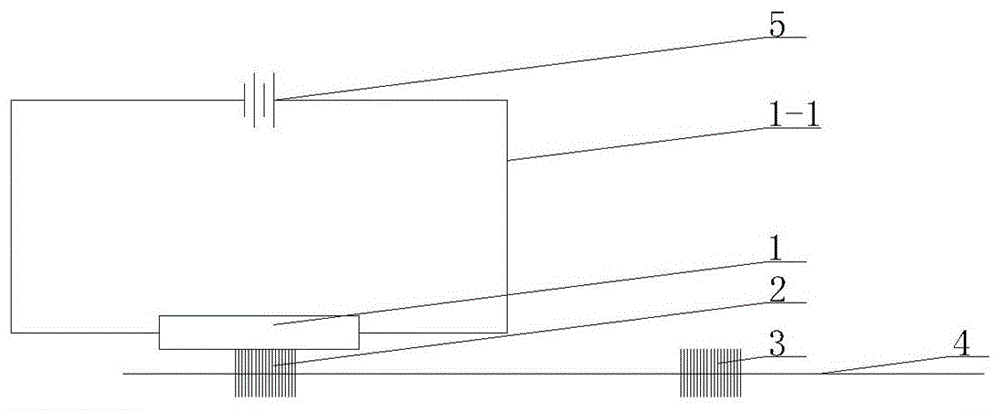

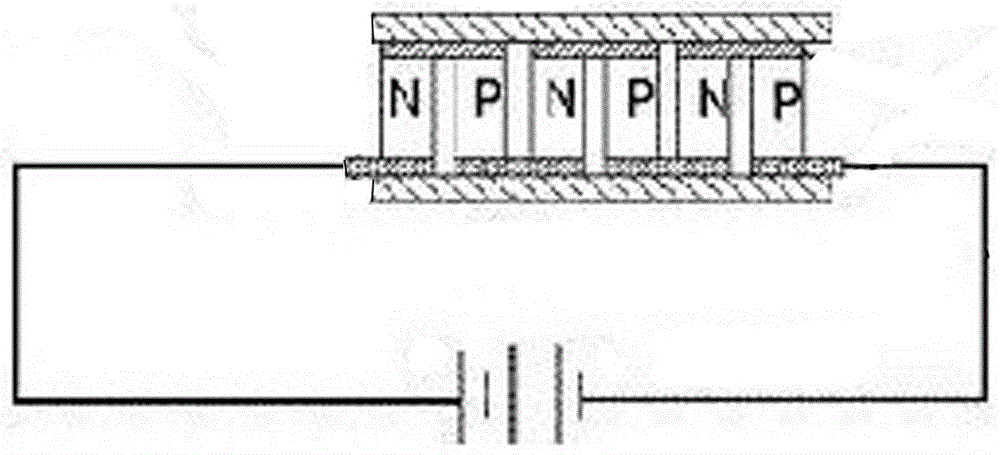

[0079] as attached figure 1 As shown, the current sensor in this embodiment includes a semiconductor cooler 1 , a test grating 2 in contact with the semiconductor cooler 1 and a compensation grating 3 connected in series with the test grating 2 . Among them, the semiconductor cooling chip is a single-stage cooling chip, and the manufacturer and model are Hebei Yuxiang Electronics TEC1-12705; the test grating is a C-band apodized fiber grating, and the manufacturer and model are GE-FBG1 gratings of Hebei Dijing Optoelectronics Technology Co., Ltd.; compensation The grating is a C-band apodized fiber grating, and the manufacturer and model are GE-FBG1 gratings from Hebei Dijing Optoelectronics Technology Co., Ltd. The current sensor of this embodiment also includes a lead wire 1-1 drawn from the semiconductor refrigeration chip 1 and an optical fiber 4 connected to the test grating 2 and the compensation grating 3, and the end of the optical fiber 4 is connected to a fiber grati...

Embodiment 2

[0091] as attached figure 1 As shown, the current sensor in this embodiment includes a semiconductor cooler 1 , a test grating 2 in contact with the semiconductor cooler 1 and a compensation grating 3 connected in series with the test grating 2 . Among them, the three-stage cooling chip is composed of three single-stage cooling chips connected in series, the semiconductor cooling chip is a single-stage cooling chip, the manufacturer and model are Hebei Yuxiang Electronics TEC1-12705; the test grating is a C-band apodized fiber grating, the manufacturer and The model is GE-FBG1 grating of Hebei Dijing Optoelectronics Technology Co., Ltd.; the compensation grating is C-band apodized fiber grating, and the manufacturer and model are GE-FBG1 gratings of Hebei Dijing Optoelectronics Technology Co., Ltd. The current sensor of this embodiment also includes a lead wire 1-1 drawn from the semiconductor refrigeration chip 1 and an optical fiber 4 connected to the test grating 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com