Slide block side core-pulling mechanism

A side core-pulling and slider technology, which is applied in the field of slider side core-pulling mechanism, can solve the problem that the slider and the mold core cannot be returned by breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

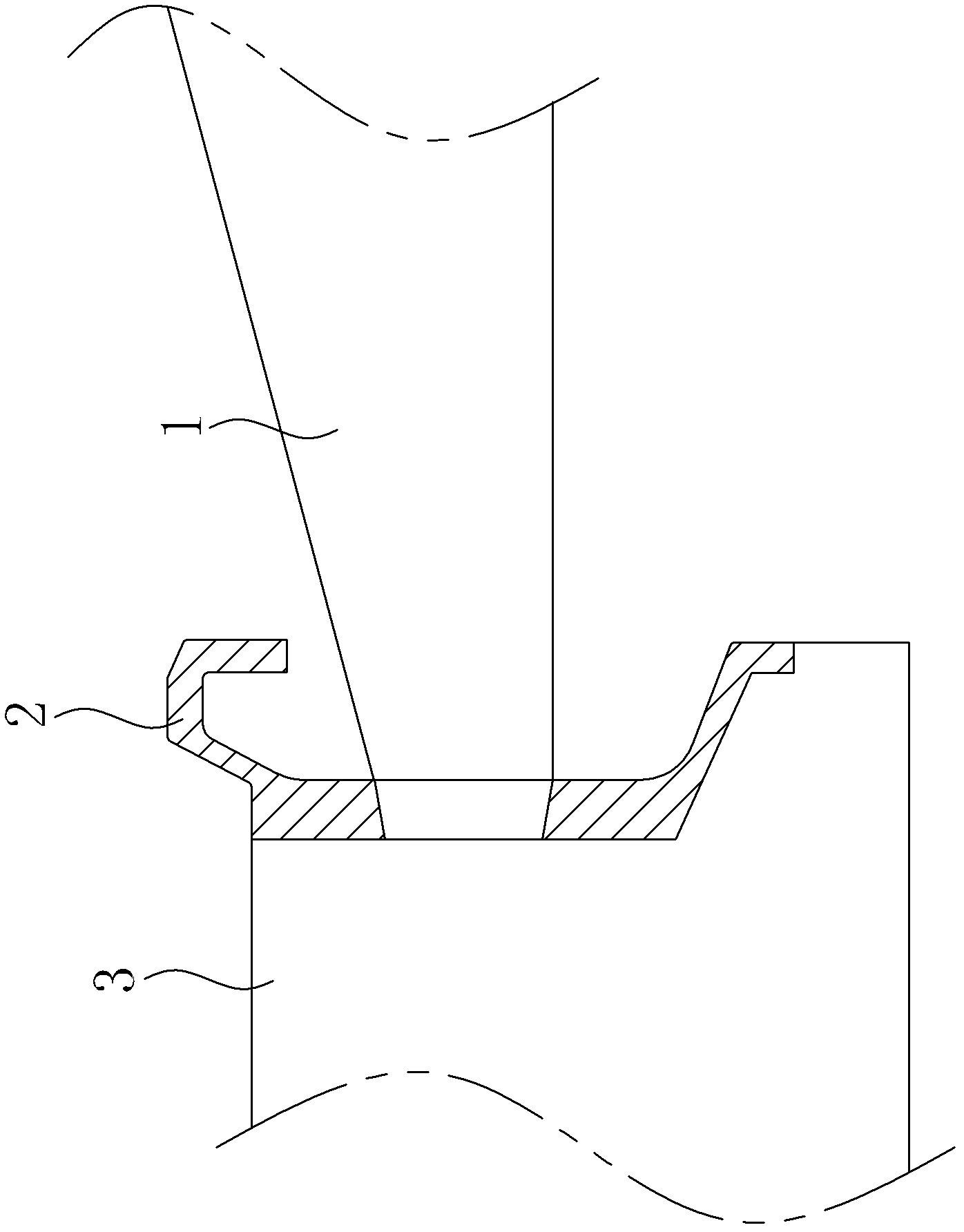

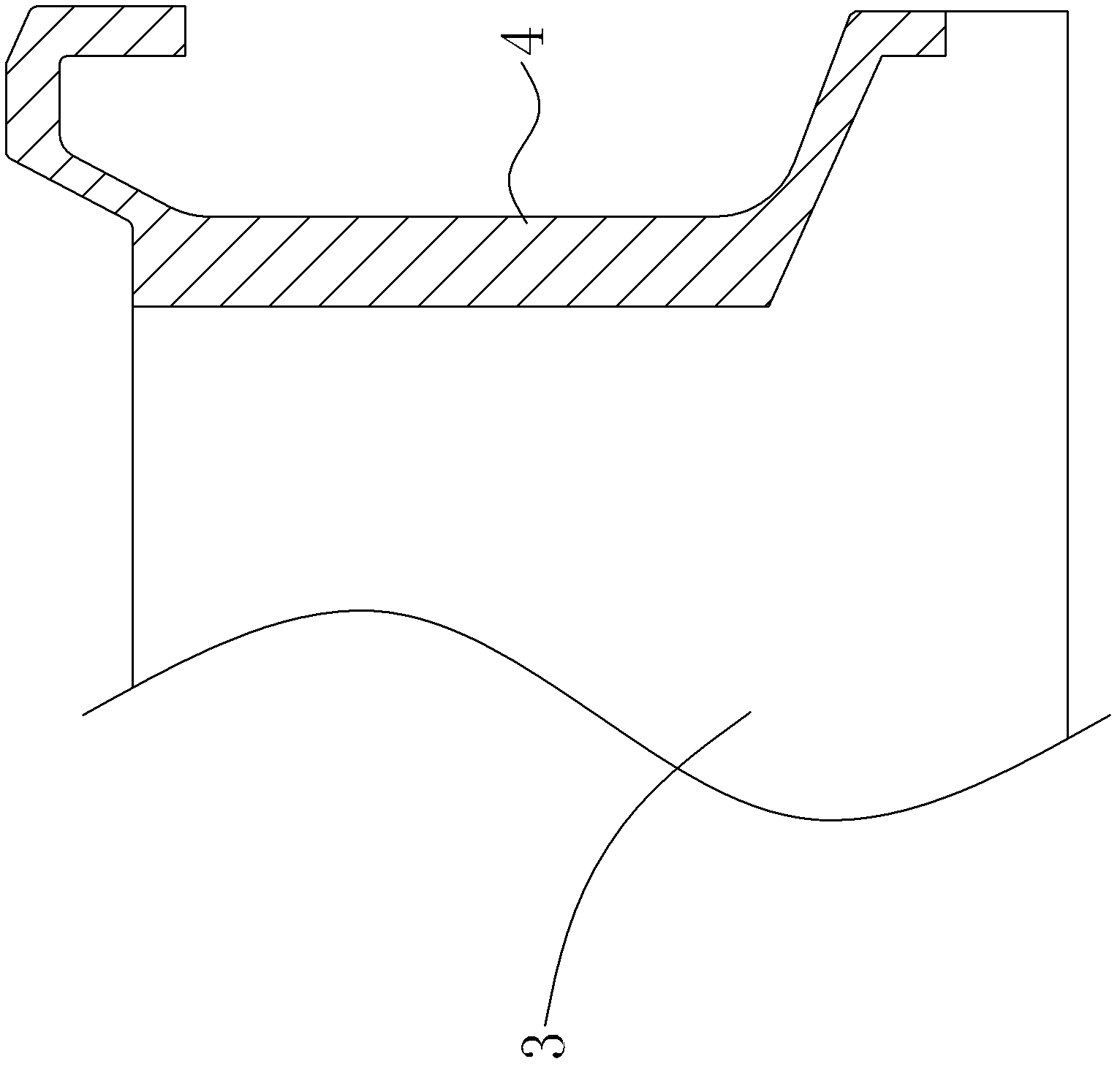

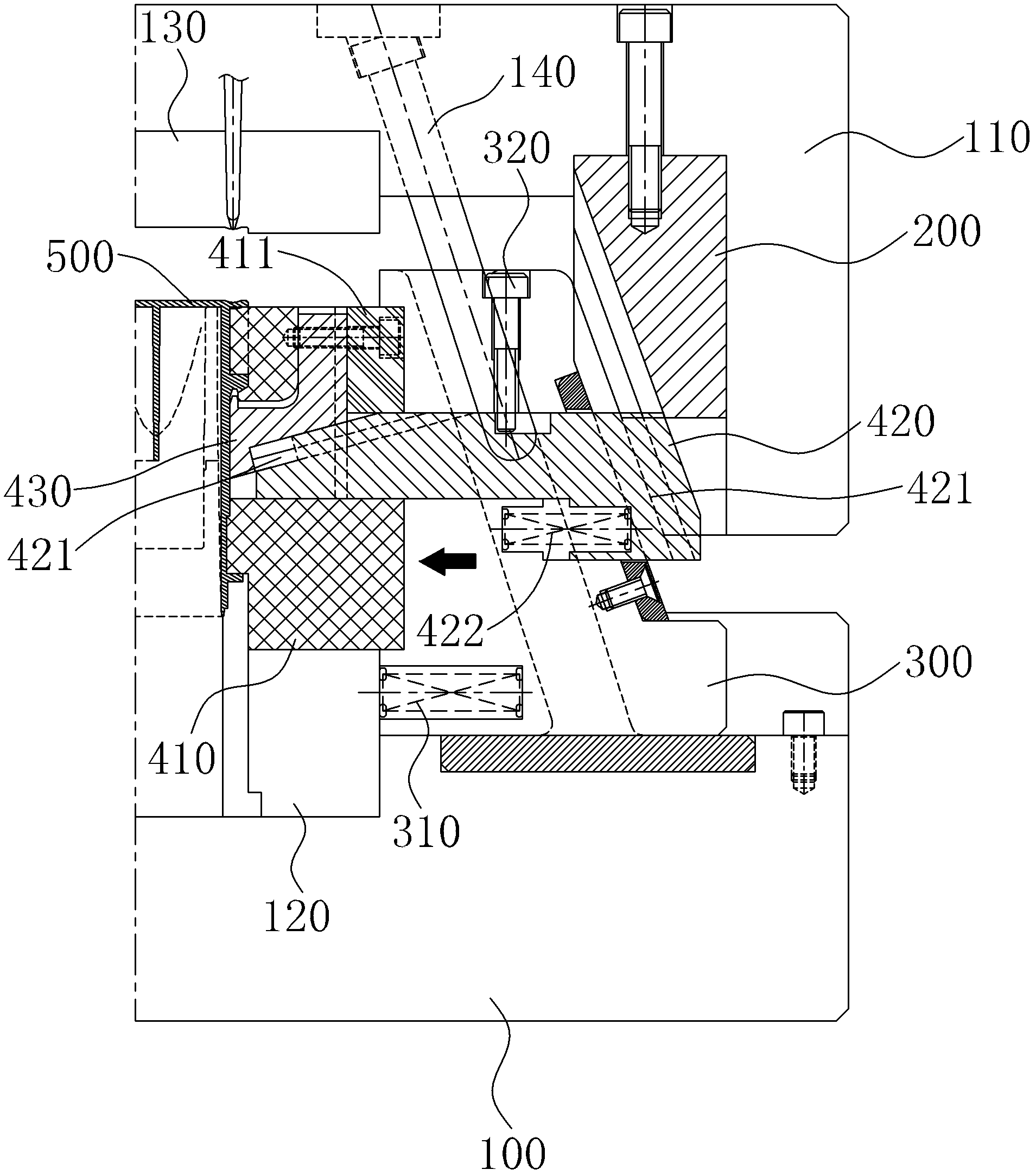

[0025] see Figure 3 to Figure 5 As shown, the slider-side core-pulling mechanism of the present invention is applied in a plastic mold, and the plastic mold includes: a male template 100, a female template 110, a male mold core 120, a female mold core 130, and an inclined guide post 140. The block side core pulling mechanism includes:

[0026] A bundle block 200, one end of which is arranged on the above-mentioned master template 110, and the other end of the bundle block 200 is provided with a T-shaped bump;

[0027] Slider body 300, one end of which is set in the above-mentioned male template 100, one end of the above-mentioned slanted guide post 140 is set in the slider body 300, and the slider body 300 is provided with a corresponding accommodation space for one end of the above-mentioned slanted guide post 140. Among them, a first elastic element 310 is provided between the slider body 300 and the male mold core 120, and the first elastic element 310 is a spring;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com