Continuous press frame assembly and continuous press

A frame and press technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of increasing the difficulty and cost of processing, the shaft frame cannot be installed separately, and the accuracy is reduced, so as to achieve easy cleaning and lubrication, and maintain long-term effectiveness , The effect of reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

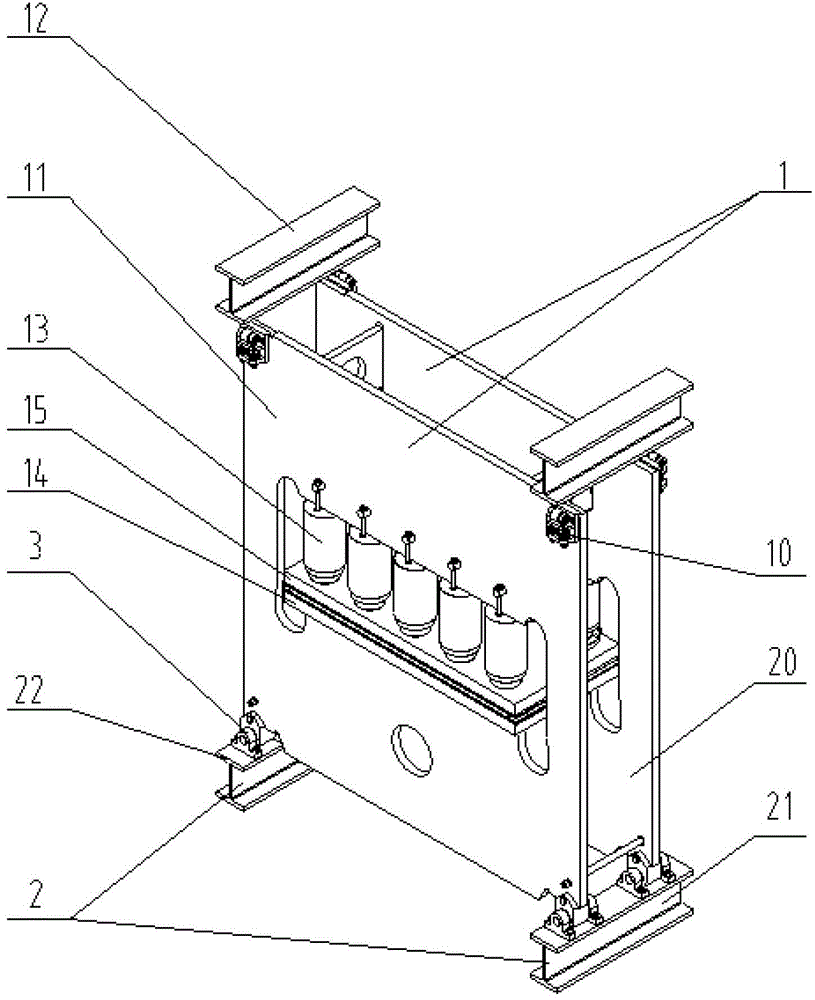

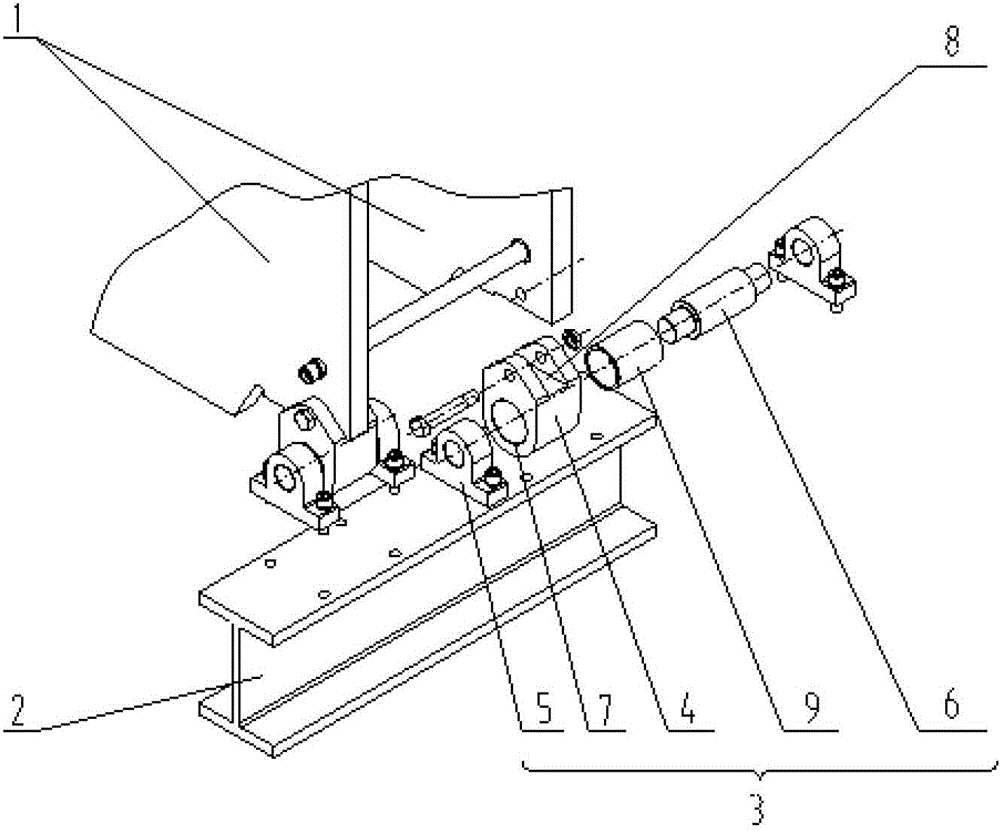

[0028] see figure 1 and figure 2 , the continuous press frame assembly of the present invention includes: a press frame 1 , an underframe 2 , and at least one sliding shoe 3 , and the press frame 1 is supported on the underframe 2 through the at least one sliding shoe 3 .

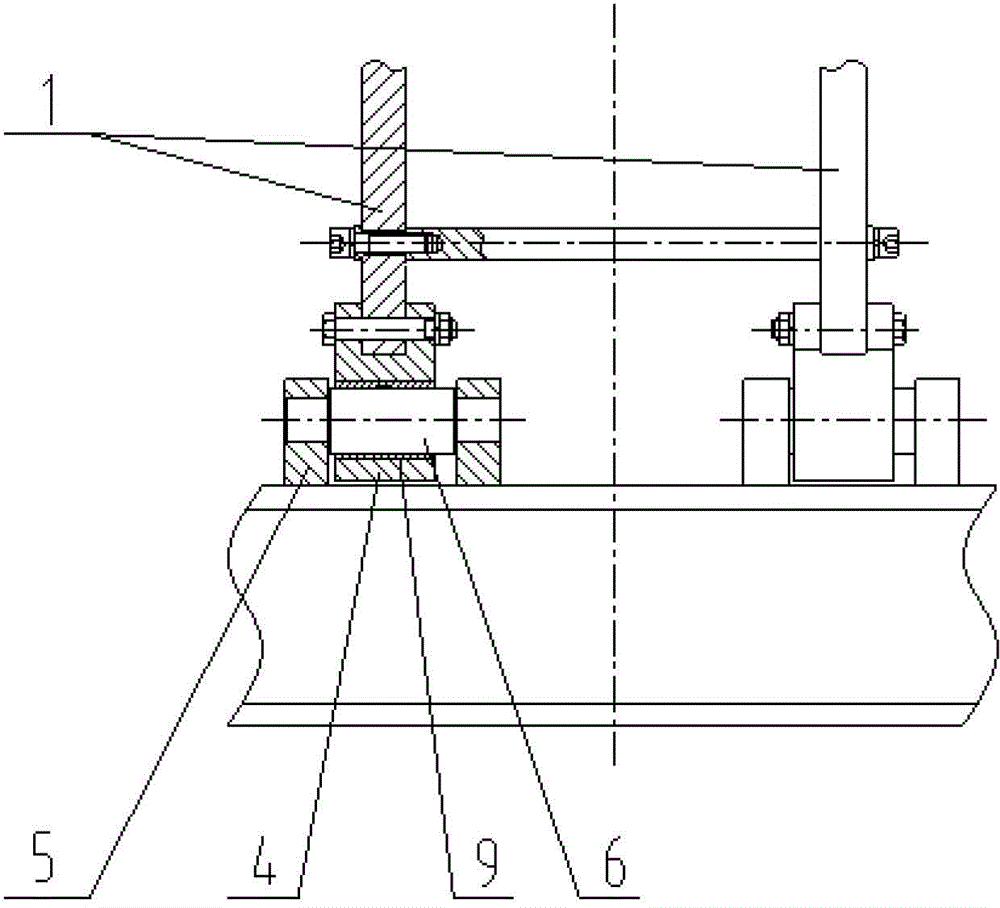

[0029] Such as figure 2 As shown in , the shoe 3 includes: a support block 4 , a bearing 5 and a support shaft 6 . The support shaft 6 is arranged in the support 5 , and the support block 4 is provided with a circumferentially closed through hole 7 , through which the support block 4 is slidably sleeved on the support shaft 6 . Thus, a circumferentially closed sliding pair is formed between the through hole 7 of the support block 4 and the support shaft 6 . Through this circumferentially closed sliding pair, the support block 4 can slide along the axial direction of the support shaft 6 . In other words, the press frame 1 is supported by the support block 4 of the slide shoe 3, and the press frame 1 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com