Fuel gas combustor

A burner and gas technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as deflagration, uneven mixing, impure gas components of oil well associated gas, etc., and achieve full combustion and high combustion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

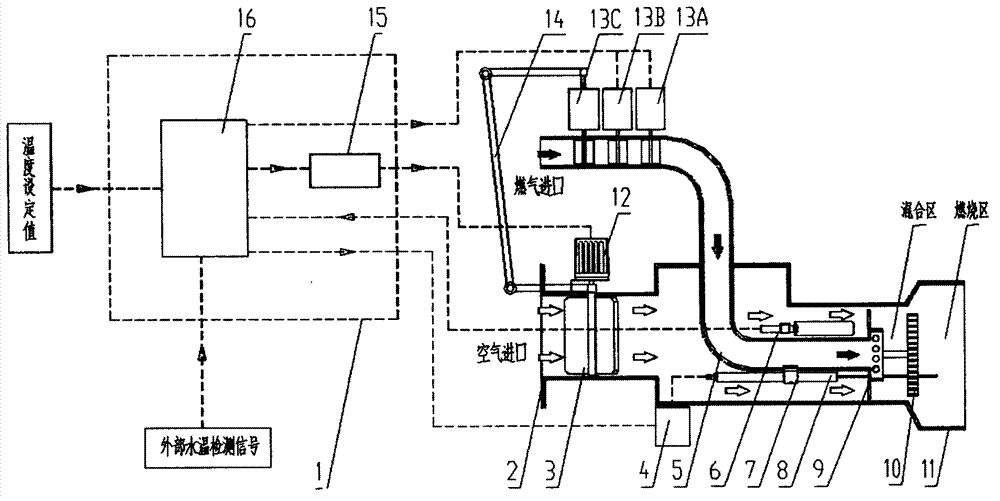

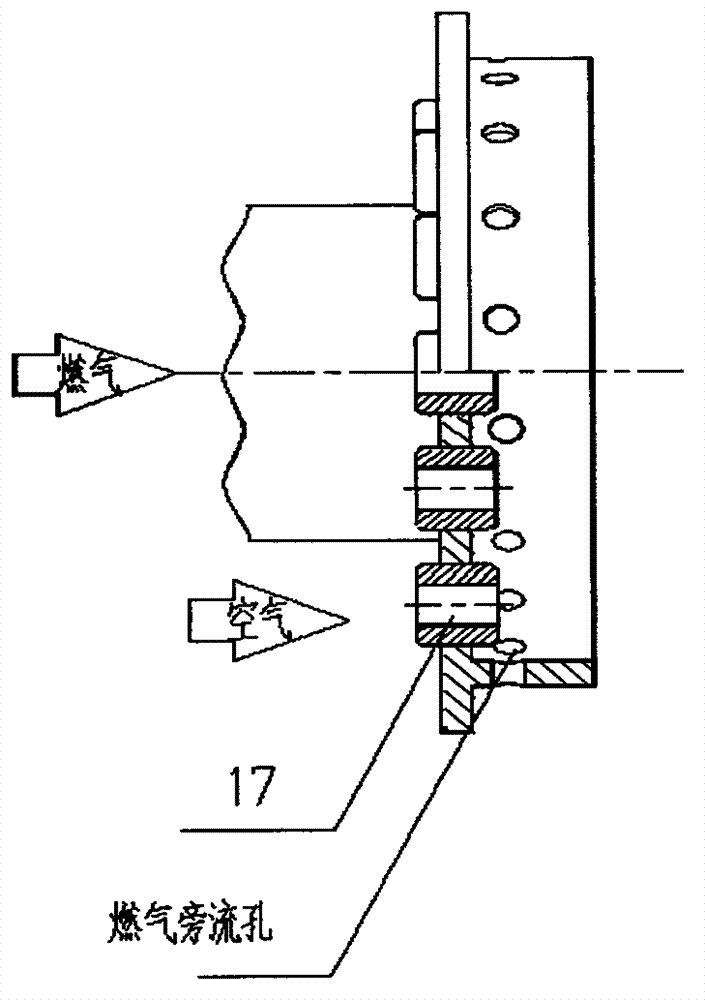

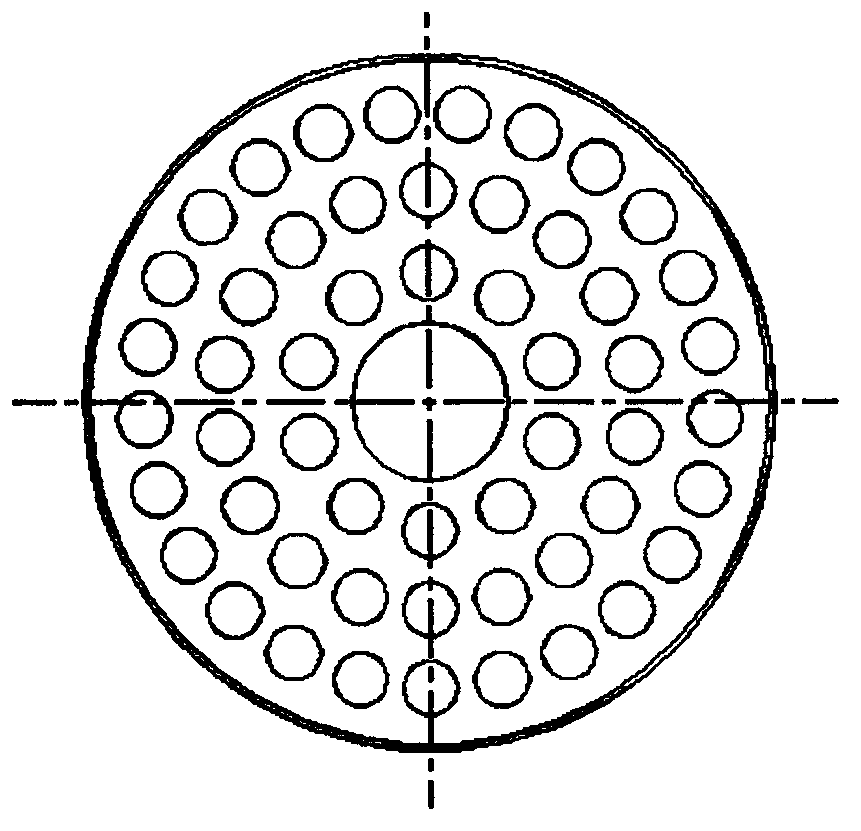

[0022] Such as figure 1 As shown, the present invention includes a gas supply and combustion system, an air supply system, and a control system 1. The gas supply and combustion system includes a gas pipe 5, a combustion cylinder 11, and the gas pipe 5 extends into the combustion cylinder 11; the air supply system includes air The duct 2 and the damper 3, and the duct 2 is connected to the combustion cylinder 11; along the flow direction of the gas, the gas pipe 5 is sequentially connected with a flow control valve 13C, an electromagnetic safety valve 13B, an on-off valve 13A, a main combustion head 9 and a flame stabilizing plate 10 , The main combustion head 9 and the flame stabilizing plate 10 are provided with through holes in the middle, the main combustion head 9 is provided with air splitting holes, the flame stabilizing plate 10 is provided with diversion holes, and the diversion holes on the flame stabilizing plate 10 are Multi-layer concentric circles are evenly distrib...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap