Nozzle-locating insulator having spring-noncontact sections interposed between spring-contact sections

A technology of insulators and nozzles, applied in the direction of injection devices, etc., can solve the problems of easy cracking, expensive manufacturing, and high flammability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

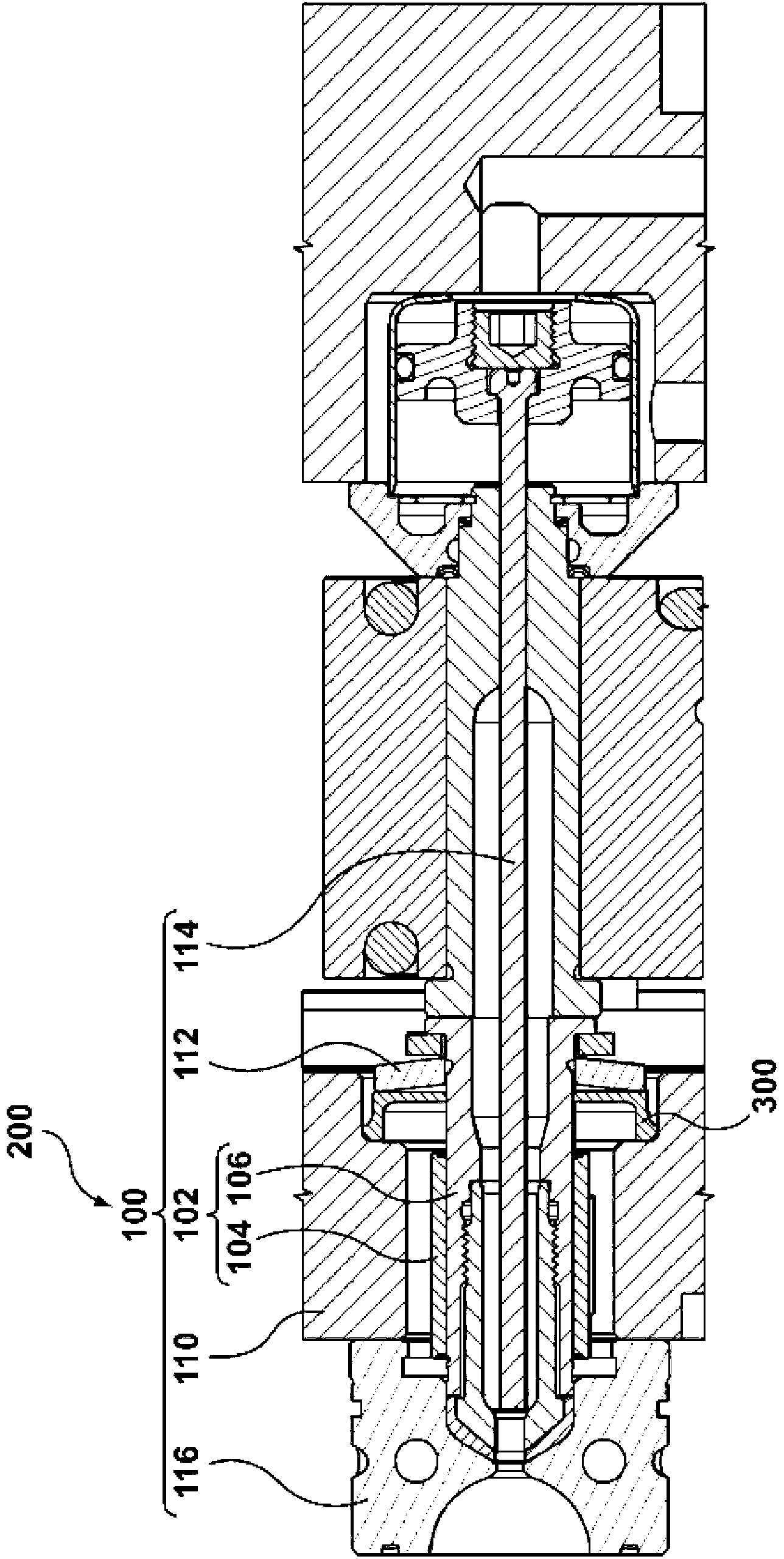

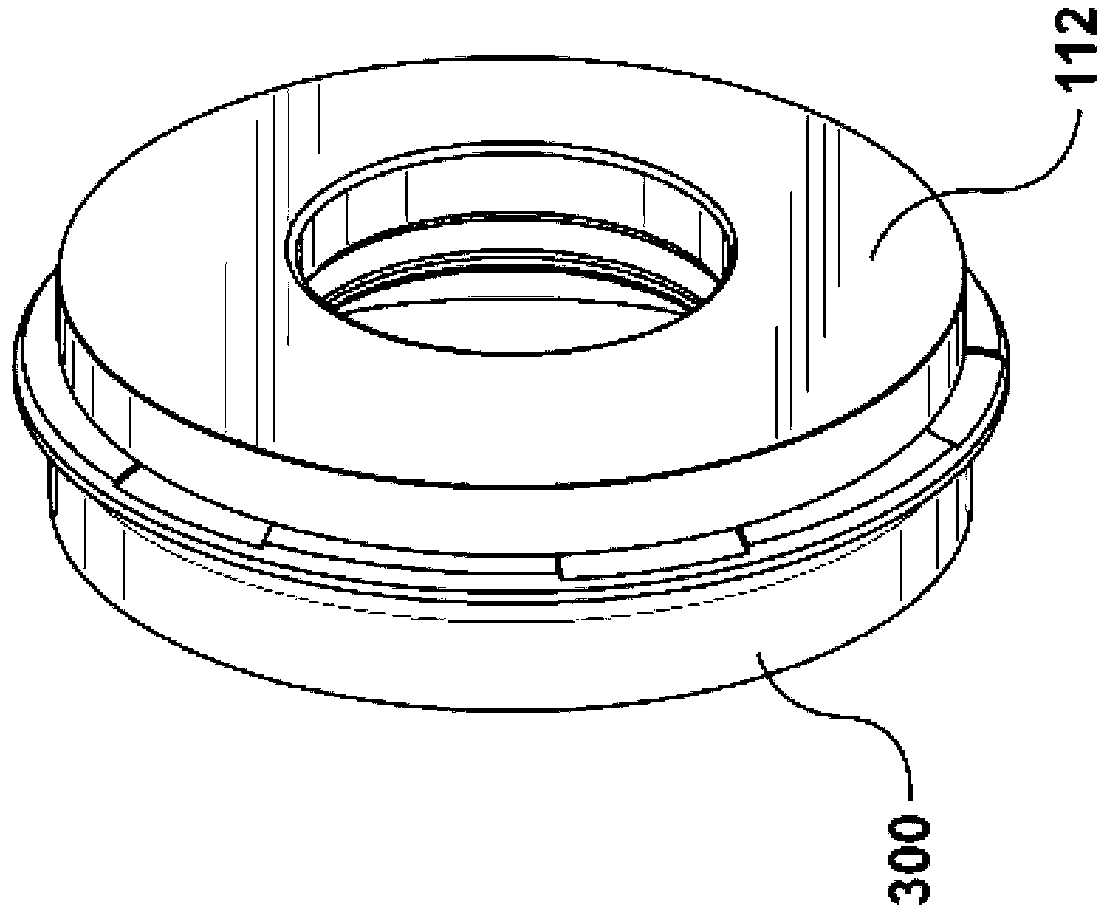

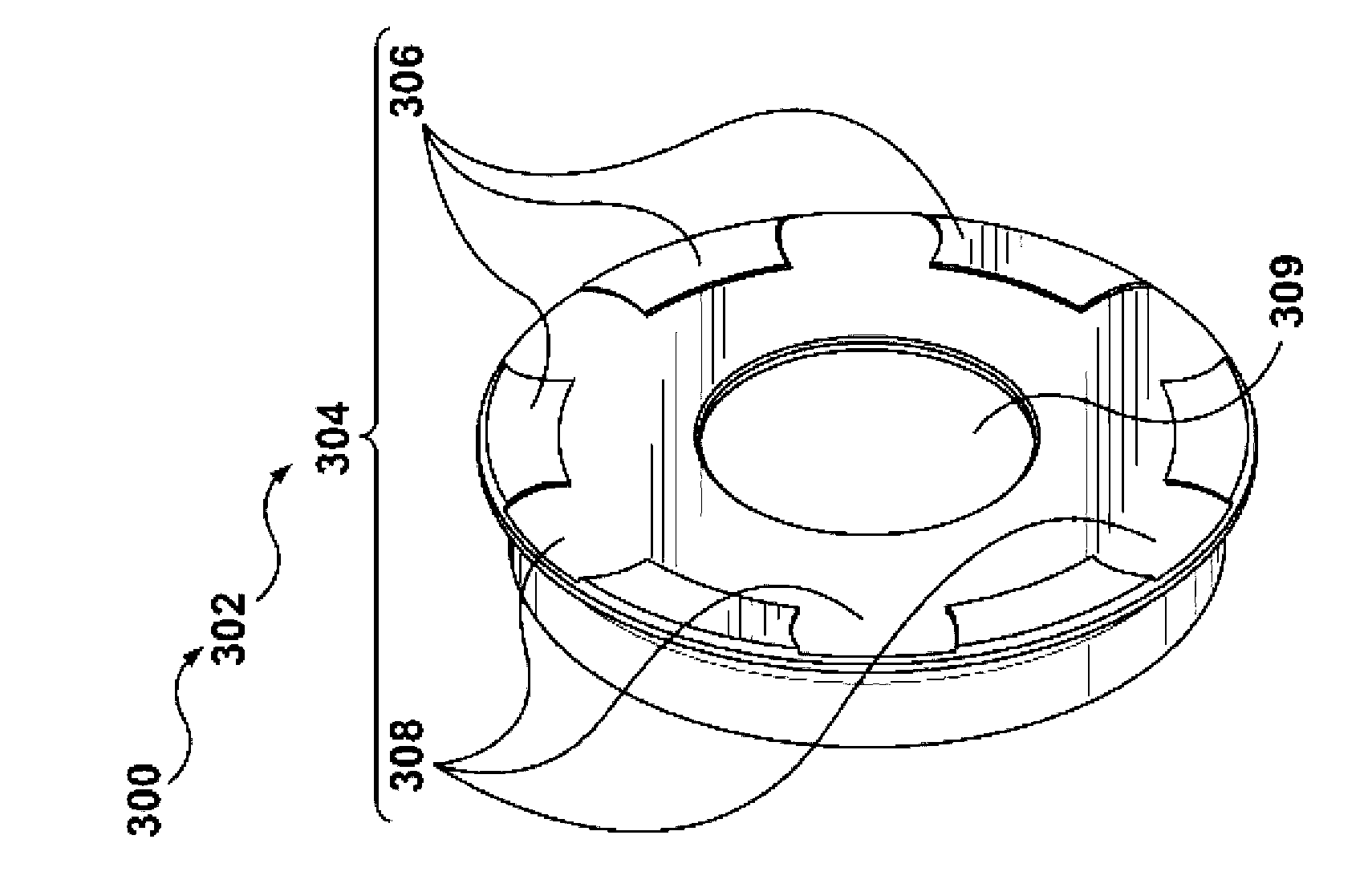

[0012] figure 1 A schematic representation (specifically, a cross-sectional view) is depicted of the nozzle positioning insulator (300), molding tool system (100) and molding system (200). The molding tool system (100) may have a nozzle positioning insulator (300). The molding system (200) may have a molding tool system (100). It should be appreciated that nozzle positioning insulator (300), molding tool system (100), and molding system (200) may be sold separately or provided by a single supplier. The molding system ( 200 ) includes, for example, a platen assembly (not depicted, but known) having a stationary platen and a movable platen. The molding tool system is supported by the platen assembly of the molding system. Each of nozzle positioning insulator (300), molding tool system (100), and molding system (200) may include, but is not limited to, components known to those skilled in the art, and such known components will not be described herein ; these known components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com