A kind of phenylboronic acid organic gel compound

A compound, aminophenylboronic acid technology, applied in the field of chemistry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

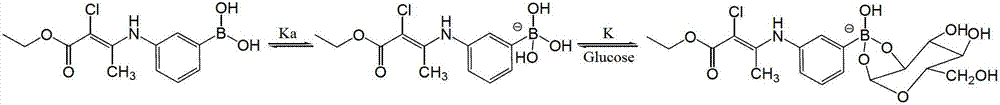

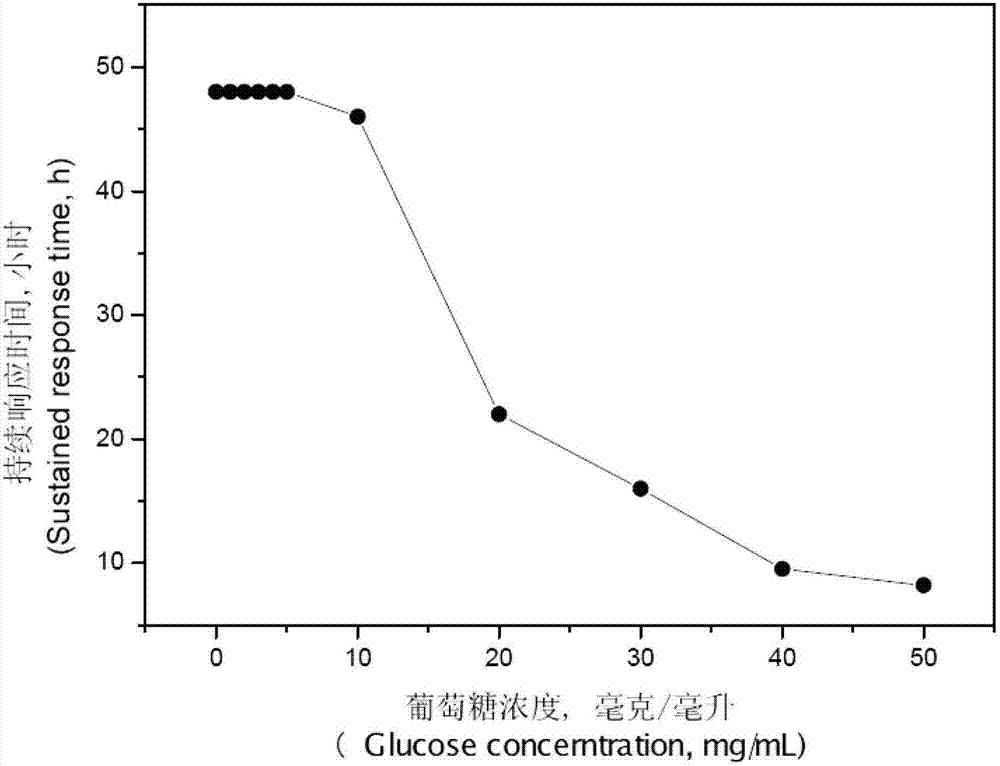

[0028] Add 30 mL of chloroform, 3-aminophenylboronic acid (1.37 g, 10 mmol), and neopentyl glycol (1.04 g, 10 mmol) into a 100 mL round bottom flask, and stir at room temperature for 3 h. The reaction solution was washed twice with 200mL water, the organic phase was separated, dried with anhydrous sodium sulfate and filtered, and the organic phase was rotary evaporated to obtain compound (3) (C 11 h 16 BNO 2 ,3-(5,5-dimethyl-1,3,2-dioxaborinan-2-yl)benzonamine), the yield was 99%. The compound (3) (7.0g, 34mmol) and ethyl 2-chloroacetoacetate (6mL, 43mmol) were added to 100mL of dichloromethane, triethylamine (7mL) was added, and the reaction was heated under reflux for 24h. After the reaction was completed, dichloromethane was removed by rotary evaporation, extracted with ethyl acetate, and the organic phase was washed three times with saturated brine. After the organic phase was rotary evaporated, it was recrystallized with isopropanol to obtain compound (2) (C 17 h 23 B...

Embodiment 2

[0030]Add 35mL of chloroform, 3-aminophenylboronic acid (1.37g, 10mmol) and neopentyl glycol (1.25g, 12mmol) into a 100mL round bottom flask, and stir at room temperature for 4h. The reaction solution was washed twice with 200 mL of water, the organic phase was separated, dried over anhydrous sodium sulfate and filtered, and the organic phase was rotary evaporated to obtain compound (3) with a yield of 99%. The compound (3) (7.0g, 34mmol) and ethyl 2-chloroacetoacetate (4.7mL, 34mmol) were added to 75mL of dichloromethane, then triethylamine (4.5mL) was added, and the reaction was heated under reflux for 15h. After the reaction was completed, dichloromethane was removed by rotary evaporation, extracted with ethyl acetate, and the organic phase was washed three times with saturated brine. After rotary evaporation, the organic phase was recrystallized with isopropanol to obtain compound (2), with a yield of 47%. Compound (2) (4.0 g, 12 mmol) was added to 40 mL of isopropanol, an...

Embodiment 3

[0032] Add 40 mL of chloroform, 3-aminophenylboronic acid (1.37 g, 10 mmol), and neopentyl glycol (1.56 g, 15 mmol) into a 100 mL round bottom flask, and stir at room temperature for 2 h. The reaction solution was washed twice with 220 mL of water, the organic phase was separated, dried over anhydrous sodium sulfate and filtered, and the organic phase was rotary evaporated to obtain compound (3) with a yield of 98%. Take the compound (3) (7.0g, 34mmol), ethyl 2-chloroacetoacetate (62mmol), add it into 100mL of dichloromethane, then add triethylamine (9mL), and heat to reflux for 30h. After the reaction was completed, dichloromethane was removed by rotary evaporation, extracted with ethyl acetate, and the organic phase was washed three times with saturated brine. After rotary evaporation, the organic phase was recrystallized with isopropanol to obtain compound (2), with a yield of 60%. Compound (2) (4.0 g, 12 mmol) was added to 60 mL of isopropanol, diethanolamine (18 mmol) was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com