Polymer, glucose-sensitive nanogel, glucose-sensitive drug-loading nanogel and their preparation methods

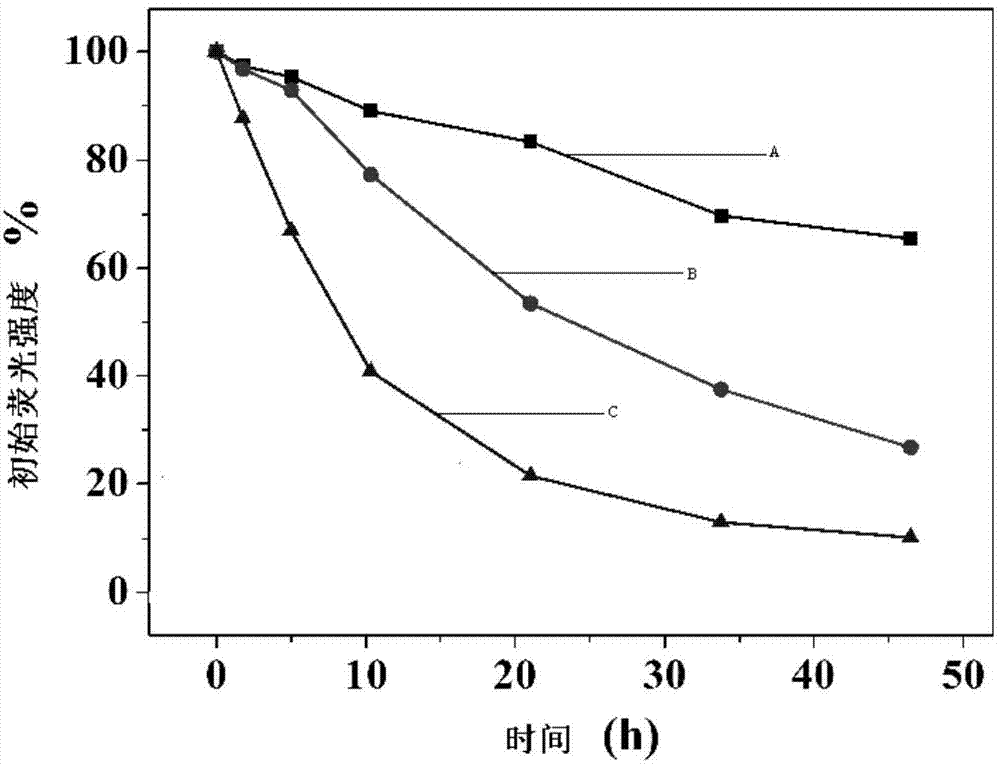

A glucose-sensitive, nano-gel technology, applied in the field of polymers, can solve the problem of increasing the biological toxicity of carrier materials, and achieve good glucose-sensitive performance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The invention discloses a preparation method of glucose-sensitive nanogel, comprising the following steps:

[0051] Crosslinking the polymer represented by formula (I) in the above technical solution with an aqueous solution of sodium perselenide in an organic solvent to obtain a polymer nanogel;

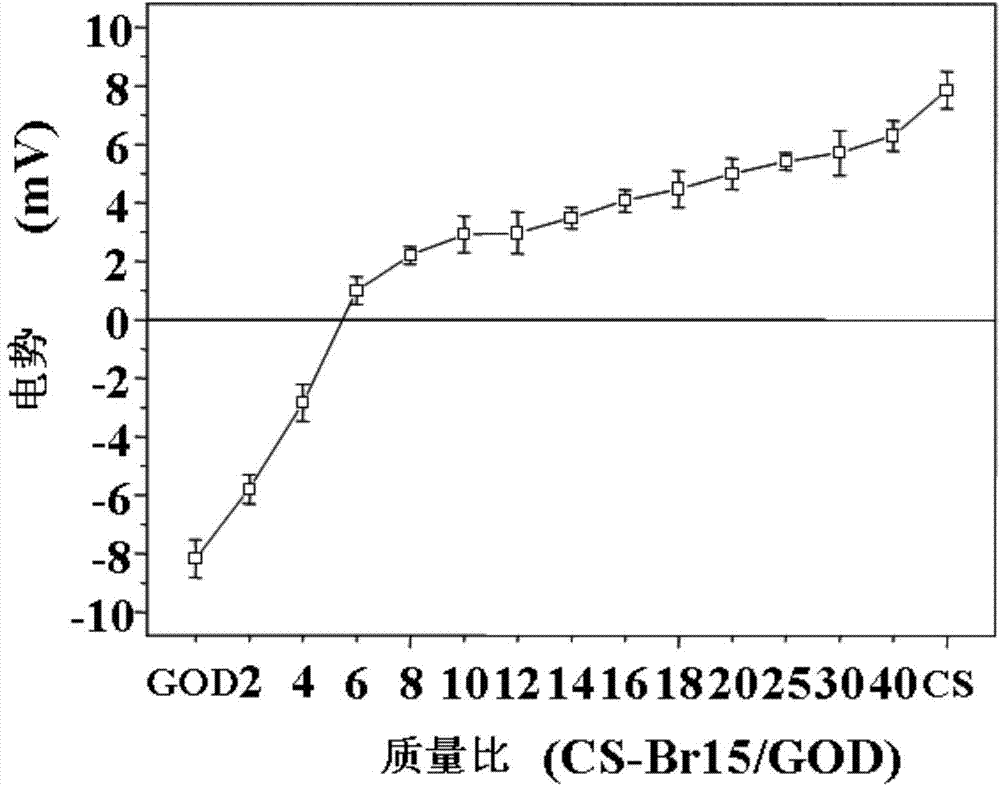

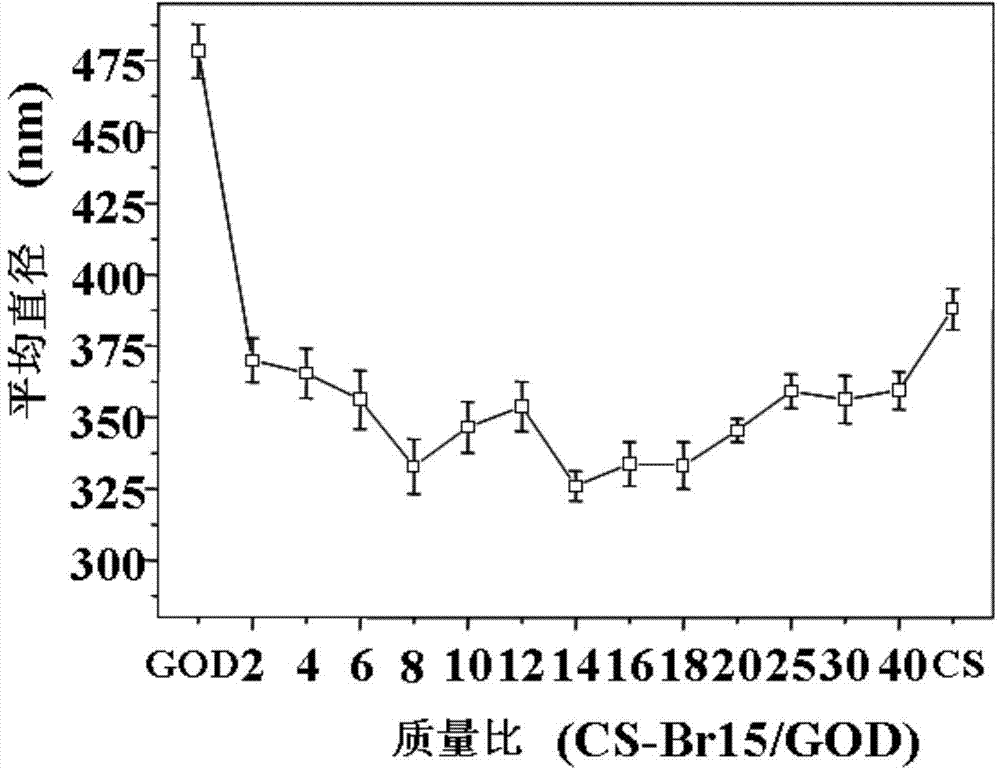

[0052] The polymer nanogel and the glucose oxidase are electrostatically compounded in an aqueous solution to obtain the glucose sensitive nanogel.

[0053] In the present invention, first, the polymer represented by the formula (I) described in the above technical solution is cross-linked with an aqueous solution of sodium perselenide in an organic solvent to prepare a polymer nanogel. The organic solvent is preferably dimethyl sulfoxide or N,N-dimethylformamide. The polymer represented by the formula (I) is preferably prepared according to the above technical scheme, and will not be repeated here. The concentration of the aqueous solution of sodium perselenide is 0.1-1 mo...

Embodiment 1

[0061] The preparation of embodiment 1 terminal carboxylated polyethylene glycol monomethyl ether

[0062] Dissolve 10g of polyethylene glycol monomethyl ether (2mmol) and 4g of succinic anhydride (40mmol) in 100mL of pyridine / dichloromethane mixed solvent (v:v=1:9), stir and react at 25°C for 48h, and the reaction ends After adding saturated NaHCO 3 The aqueous solution was neutralized and washed three times with ethyl acetate to remove unreacted pyridine. Add HCl to adjust the pH of the solution to acidity, and add NaCl to saturation, extract with chloroform, and dry with anhydrous magnesium sulfate, filter, settle and dry to constant weight to obtain carboxylated polyethylene glycol monomethyl ether. The yield is 80%.

Embodiment 2

[0063] The purification of embodiment 2 chitosan

[0064] Dissolve 5g of chitosan with 1% (v:v) acetic acid solution at 25°C, and filter to remove insoluble matter, settle with acetone, centrifuge and wash with deionized water, and filter through a G3 funnel. The acetic acid dissolution was repeated twice, washed with water and drained for later use. The yield was 69%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com