Method for generating optimized, constant curvature 2D or 3D roller profile curves and corresponding device

A technology of changing curves and continuous curvature, applied in multi-objective optimization, design optimization/simulation, CAD technology, etc., can solve limited problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

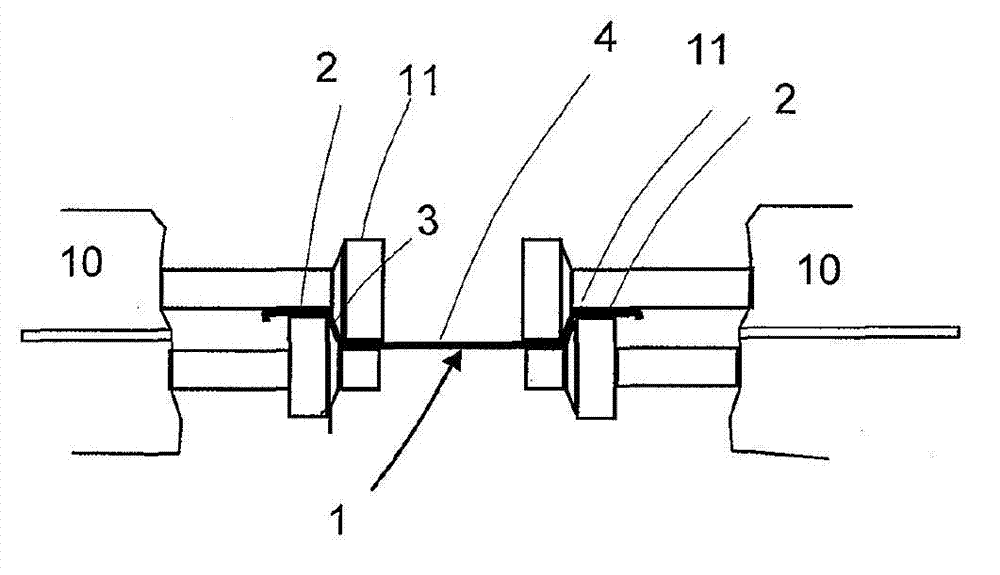

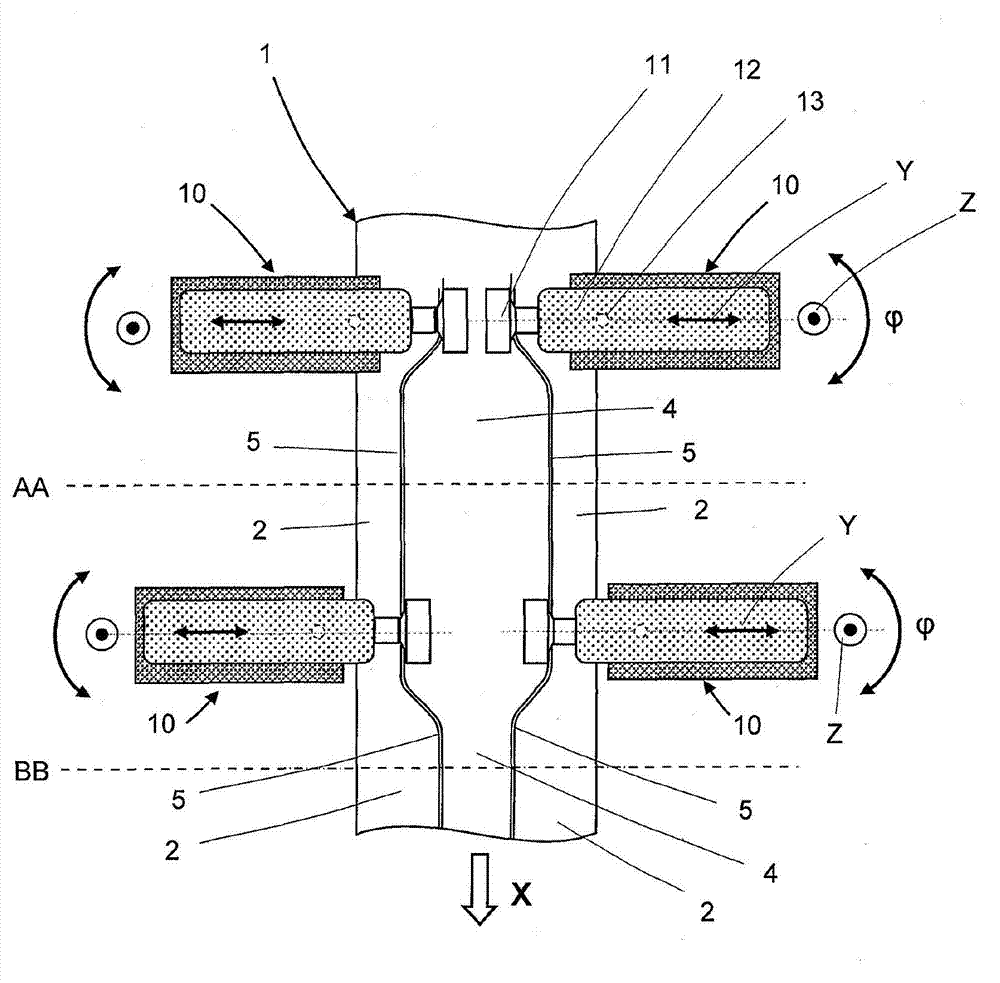

[0028] exist Figure 1A and Figure 1B An embodiment of a device for flexible roll forming is shown in , which guides and squeezes a strip 1 along a strip feed direction X between a plurality of forming rolls 11 such that the strip 1 The forming rollers 11 are deformed by pressing against each other and thereby produce a top surface 2 , a side surface 3 and a bottom surface 4 . The profiling rolls 11 are held in their respective positions and driven in each case by an associated actuator 10 with a corresponding motor 12 , wherein the profiling rolls 11 rotating about their respective axes press the strip 1 and run with it. Or preferably also driven by the motor 12 .

[0029] The corresponding position and orientation of the forming roll 11 and the motor 12 connected thereto and the partial actuators are brought about in the form of actuation by corresponding actuators 10 , whereby the actuators 10 can be rotated in the transverse direction Y, in the vertical direction Z and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com