Film sample stretching device used for being matched with atomic force microscope (AFM)

An atomic force microscope and stretching device technology, applied in scanning probe technology, instruments, etc., can solve the problems of high production cost, cannot meet the needs of ordinary atomic force microscope users, and the maximum strain cannot meet high strain rate materials, etc. The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

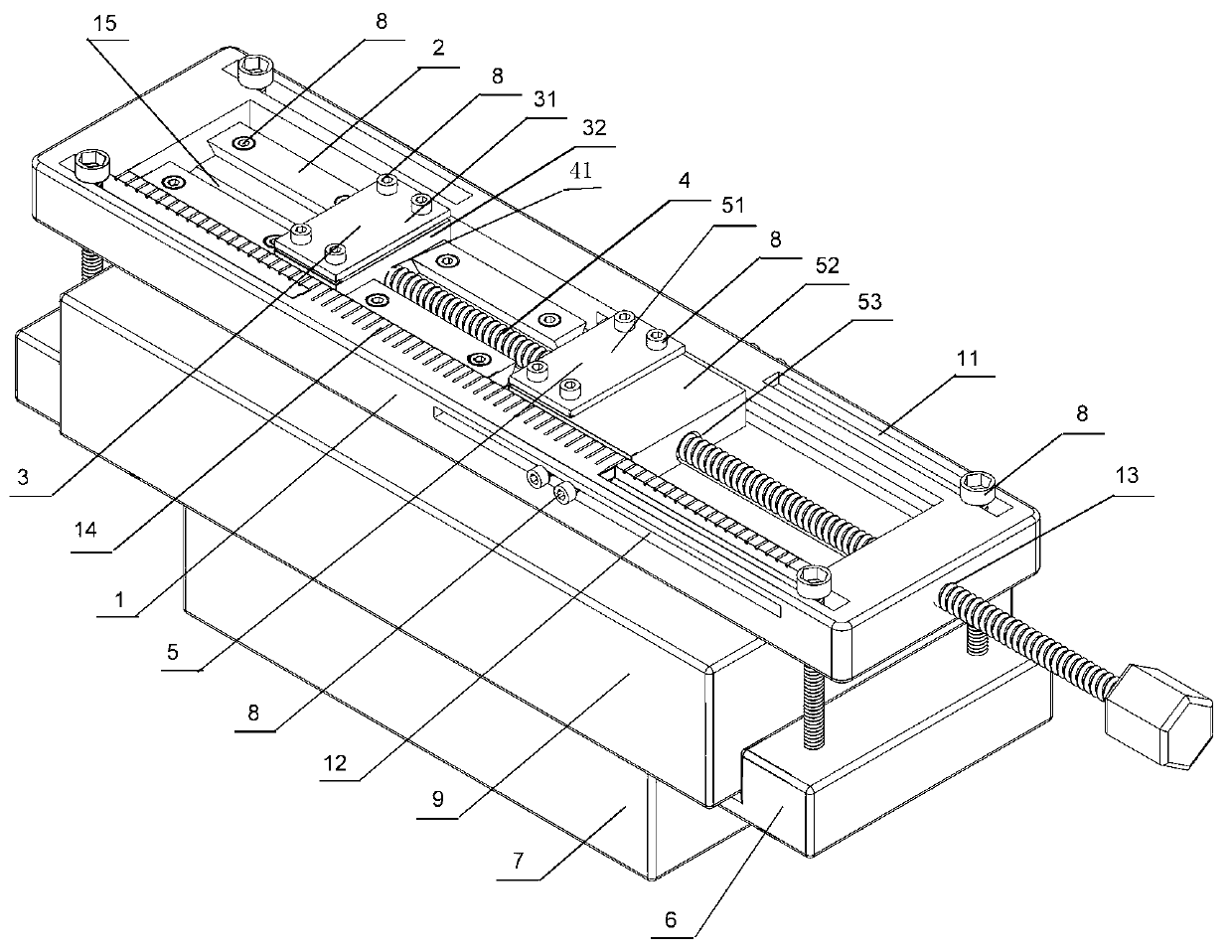

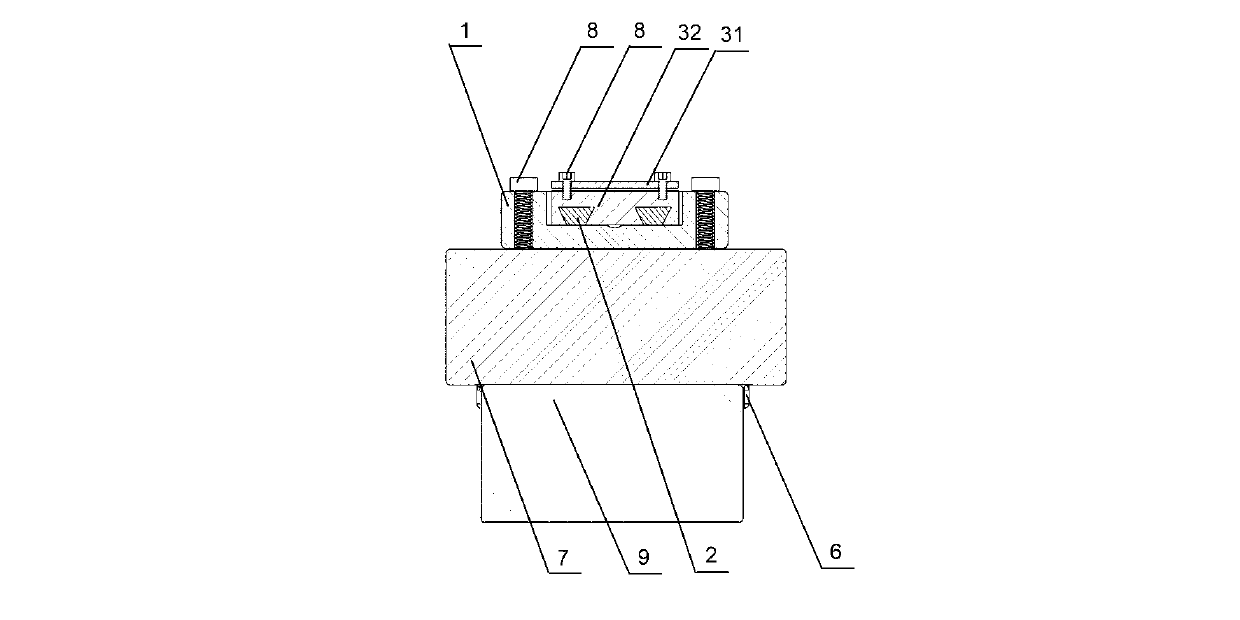

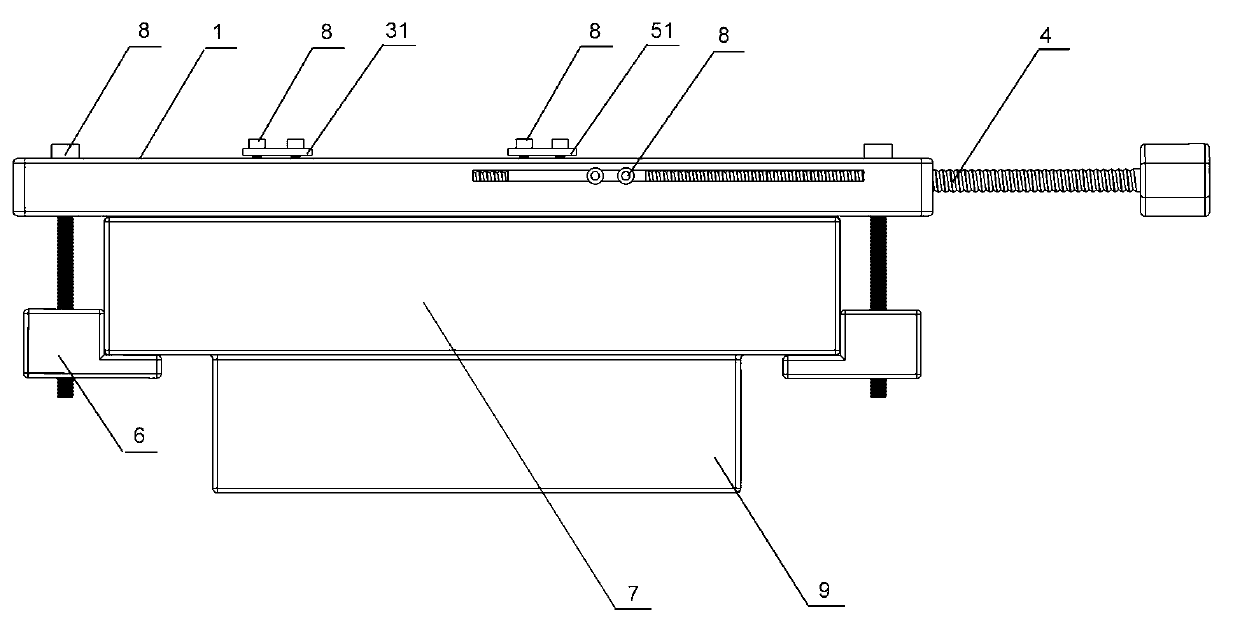

[0019] Preferred embodiments of the present invention are described as follows in conjunction with the accompanying drawings:

[0020] When the present invention is used, the device can be fixed on the test sample platform 7, and the test sample platform can be placed on the test shockproof platform 9.

[0021] A sample stretching device for an atomic force microscope, a base 1 is provided with an inner groove 15, and guide rails 2 are provided on both sides of the groove at the front of the base; The holes are threaded; the push screw passes through the center hole 53 of the right fixture 5 and pushes against the left fixture 3; the right fixture 5 is fixed in the rear part groove of the base; the left fixture is located on the guide rail and is slidably connected with the guide rail. The cross-sectional shape of the track can be wide at the top and narrow at the bottom, and is fixedly connected with the base by bolts 8 . The left fixture is stuck on the track and will not b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap