Device, system and method for producing a magnetically induced visual effect

A visual effect, magnetic induction technology, applied to the equipment of the electric recording process using the charge pattern, the copying/marking method, the electric recording process using the charge pattern, etc., which can solve registration problems, swelling, reduce paper moisture content, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

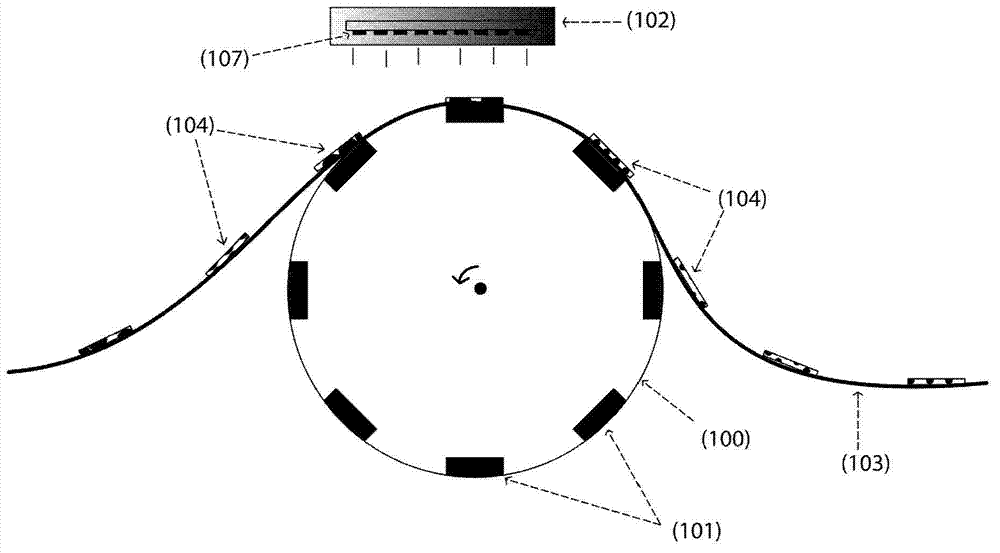

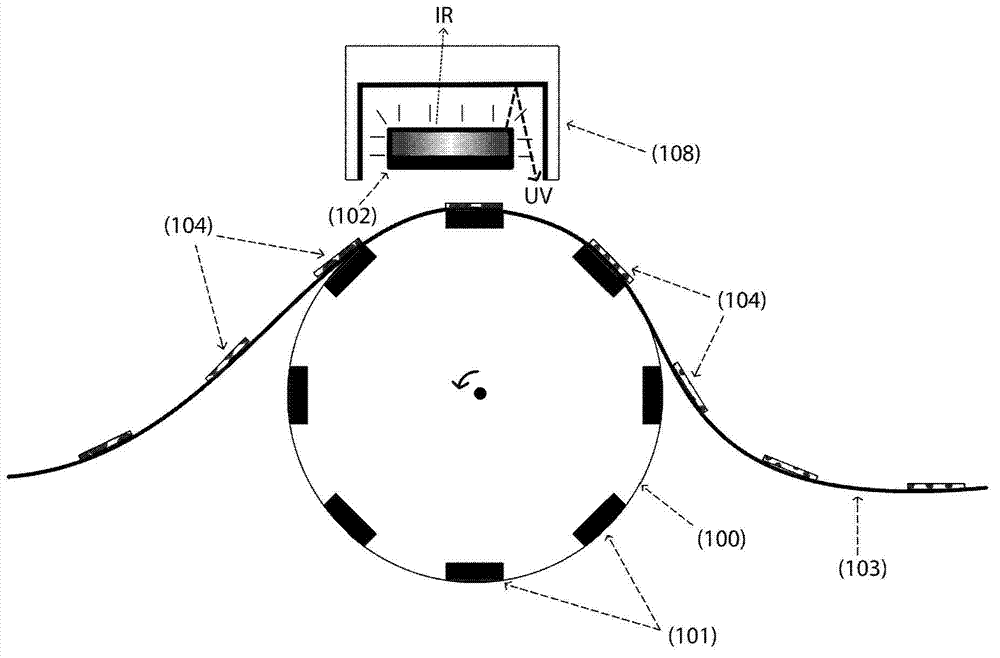

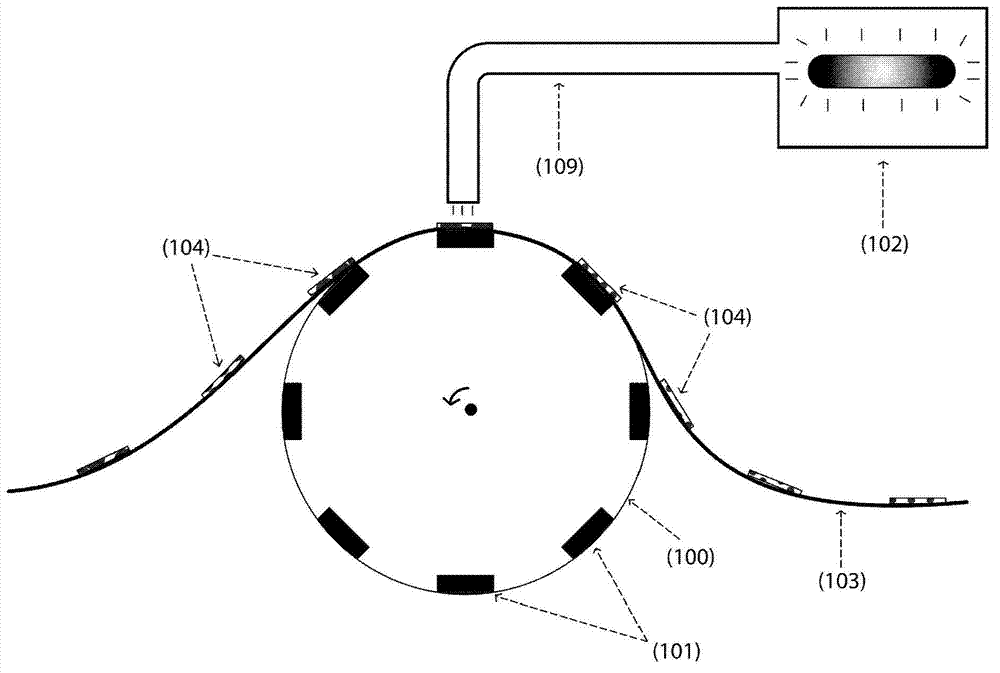

[0038] Figures 1 to 4a -c shows a preferred embodiment of the invention, in which an apparatus for generating magnetically induced visual effects by printing and curing security or decorative features based on orientable magnetic particles comprises an optical curing unit. Figure 5 and Figure 6Different preferred realizations of the substrate guiding system are shown which keep the substrate (thin layer) carrying the coating composition in close contact with the magnetic cylinder.

[0039] Here, the term "magnetic drum" refers to a cylinder carrying at least one magnetic field generating element capable of orienting magnetic particles to generate a visual effect. Such magnetic field generating elements are described, for example, in EP1641624, EP1937415, US2010 / 0040845 or WO2004 / 007095.

[0040] The magnetic field generating element or elements used to orient the magnetic particles may be constructed of a wide variety of magnetic materials such as, but not limited to, ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com