Cylinder lamp front cover and cylinder lamp with the same

A front cover and downlight technology, applied in the field of lighting, can solve the problems of labor-intensive, inconvenient installation, and physical and labor-intensive installation accuracy, and achieve the effects of improving assembly efficiency, reliable installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

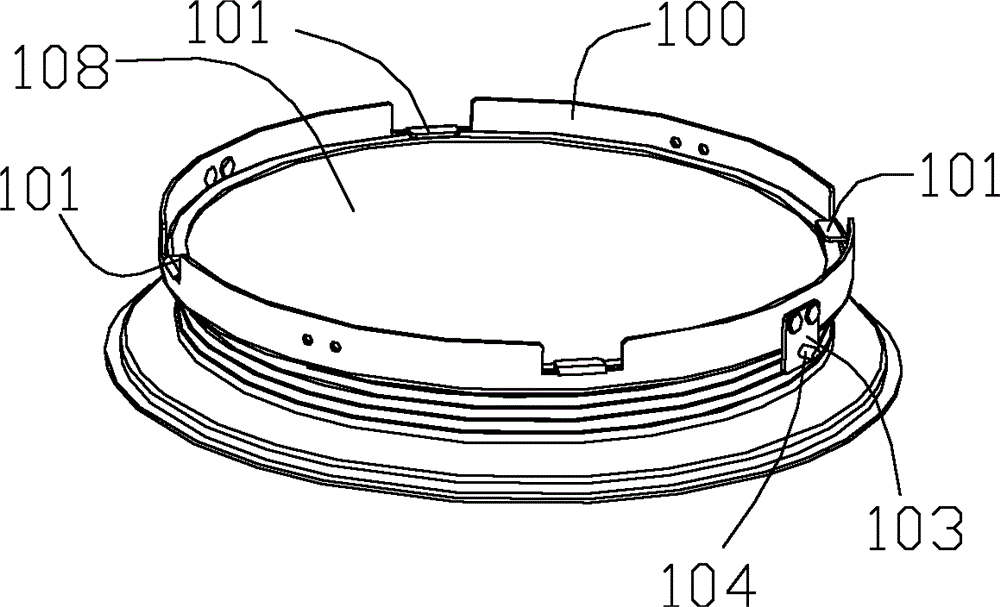

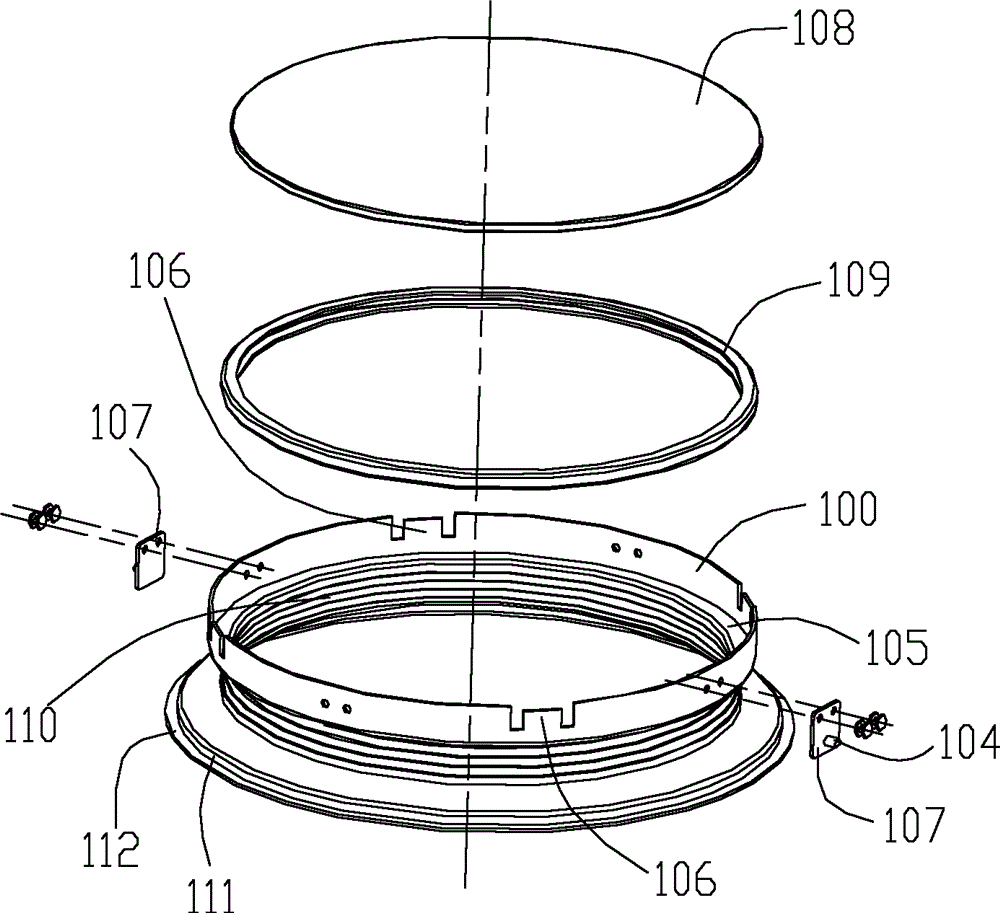

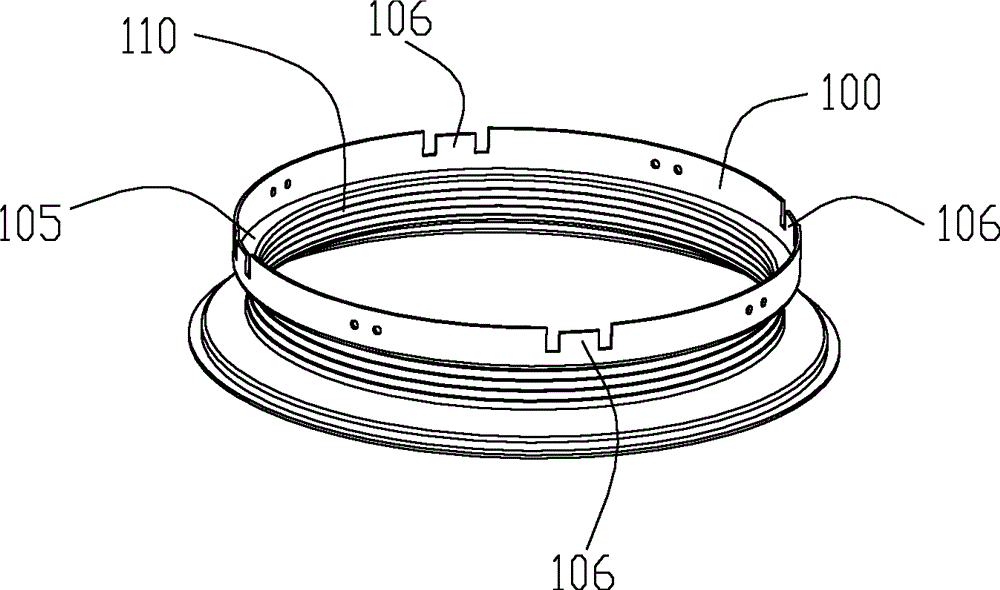

[0025] Such as Figure 1-3 As shown, in a preferred embodiment of the present invention, the front cover of the downlight includes a front cover body 100 that matches the cross-sectional shape of the open end of the downlight. The front cover body 100 is provided with a first engaging structure 101. The front cover body One end surface of 100 is provided with a transparent member 108 for passing through the downlight light through the first engaging structure 101; the outer surface edge of the front cover body 100 is also provided with a second engaging structure 103, and on the second engaging structure 103 There is a raised part 104, and the front cover body 100 is rotated so that the raised part 104 of the second engaging structure 103 fits with the recessed part 202 inside the open end of the downlight, so that the downlight body 100 is assembled into the open end of the downlight Inside. The front cover body 100 of the present invention is preferably formed by spinning a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com