A lampblack purification device and its working method

A technology for oil fume purification and purification room, which is applied in chemical instruments and methods, separation methods, electrostatic separation, etc., can solve the problems that ultraviolet rays do not have the function of purifying oil fume purification, and the purification effect is not ideal, so as to achieve high processing product efficiency and occupy less space. Small footprint and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

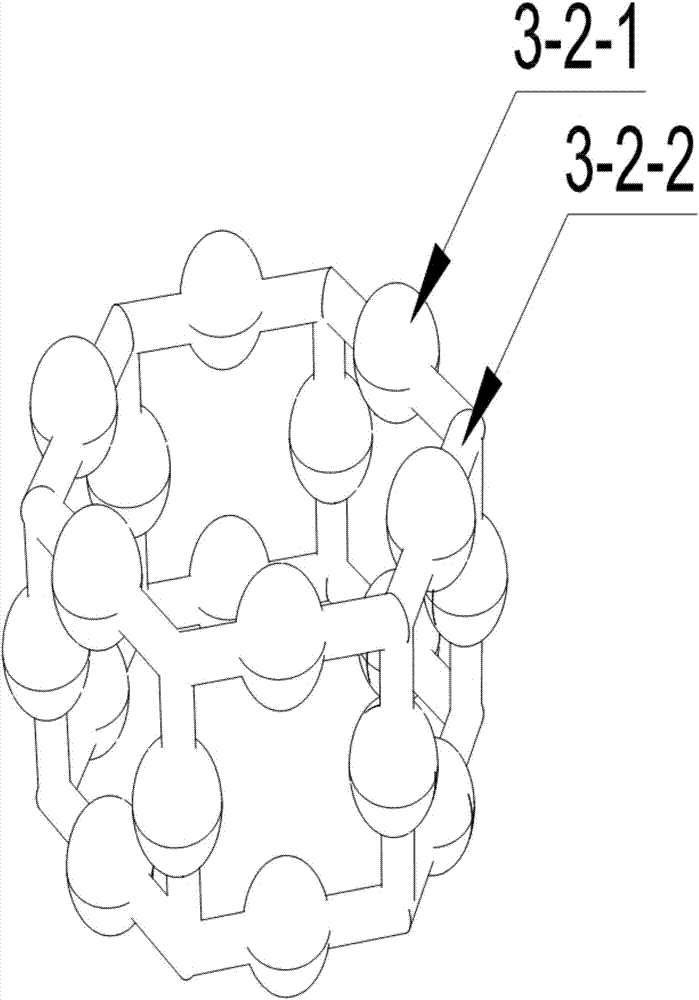

[0057] In parts by weight, the CO catalytic material 3-2 of the present invention is produced according to the following steps:

[0058] Step 1. Add 500 parts of ultrapure water with a conductivity of 0.005μS / cm into the reactor, start the stirrer in the reactor at a speed of 80rpm, start the heating pump, and raise the temperature in the reactor to 50°C; add in sequence 1 part of dimethyl methylphosphonate, 1 part of ethyl acetate, 1 part of trimethyl phosphate, stir until completely dissolved, adjust the pH value to 5.5, adjust the speed of the stirrer to 180rpm, and the temperature is 70°C, the esterification reaction 1 hour;

[0059] Step 2, take 1 part of butyl xanthate ethyl formate and 1 part of ethyl acrylate and pulverize, the particle size of the powder is 50 mesh; add 200 parts of nano-scale ruthenium borate and mix evenly, spread it in the tray, the thickness of the laying is 10.45mm, irradiated with α-rays with a dose of 2.0kGy and an energy of 0.5MeV for 5min; ...

Embodiment 2

[0065] In parts by weight, the CO catalytic material 3-2 of the present invention is produced according to the following steps:

[0066] Step 1. Add 1500 parts of ultrapure water with a conductivity of 0.05μS / cm into the reaction kettle, start the stirrer in the reaction kettle at a speed of 90rpm, start the heating pump, and raise the temperature in the reaction kettle to 70°C; add in sequence 9 parts of dimethyl methylphosphonate, 9 parts of ethyl acetate, 9 parts of trimethyl phosphate, stir until completely dissolved, adjust the pH value to 8.0, adjust the speed of the stirrer to 200rpm, and the temperature is 80°C, the esterification reaction 12 hours;

[0067] The 2nd step, take 12 parts of butyl xanthate ethyl formate, 12 parts of ethyl acrylate and pulverize, the powder particle size is 120 meshes; Add 400 parts of nano-scale ruthenium borate and mix evenly, tile in the tray, tile thickness is 15.38mm, irradiated with α-rays with a dose of 5.0kGy and an energy of 1.5M...

Embodiment 3

[0073] In parts by weight, the CO catalytic material 3-2 of the present invention is produced according to the following steps:

[0074] Step 1. Add 900 parts of ultra-pure water with a conductivity of 0.02μS / cm into the reactor, start the stirrer in the reactor at a speed of 85rpm, start the heating pump to raise the temperature in the reactor to 55°C; add in sequence 5 parts of dimethyl methylphosphonate, 5 parts of ethyl acetate, 5 parts of trimethyl phosphate, stir until completely dissolved, adjust the pH value to 6.0, adjust the speed of the stirrer to 190rpm, and the temperature is 75°C, the esterification reaction 5 hours;

[0075] Step 2, take 5 parts of butyl xanthate ethyl formate and 5 parts of ethyl acrylate to pulverize, the powder particle size is 90 mesh; add 300 parts of nano-scale ruthenium borate and mix evenly, spread it in the tray, the thickness of the spread is 13mm, irradiated with α-rays with a dose of 2.9kGy and an energy of 1.0MeV for 7min;

[0076...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com