Method for controlling width of hot rolling strip steel

A technology for width control and hot-rolled strip steel, applied in the direction of metal rolling stand, metal rolling mill stand, etc., can solve the problems of large actual width control deviation, poor interference adaptability, and inability to correct width control processing, etc., to achieve The effect of reducing the amount of correction and improving the accuracy of width control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

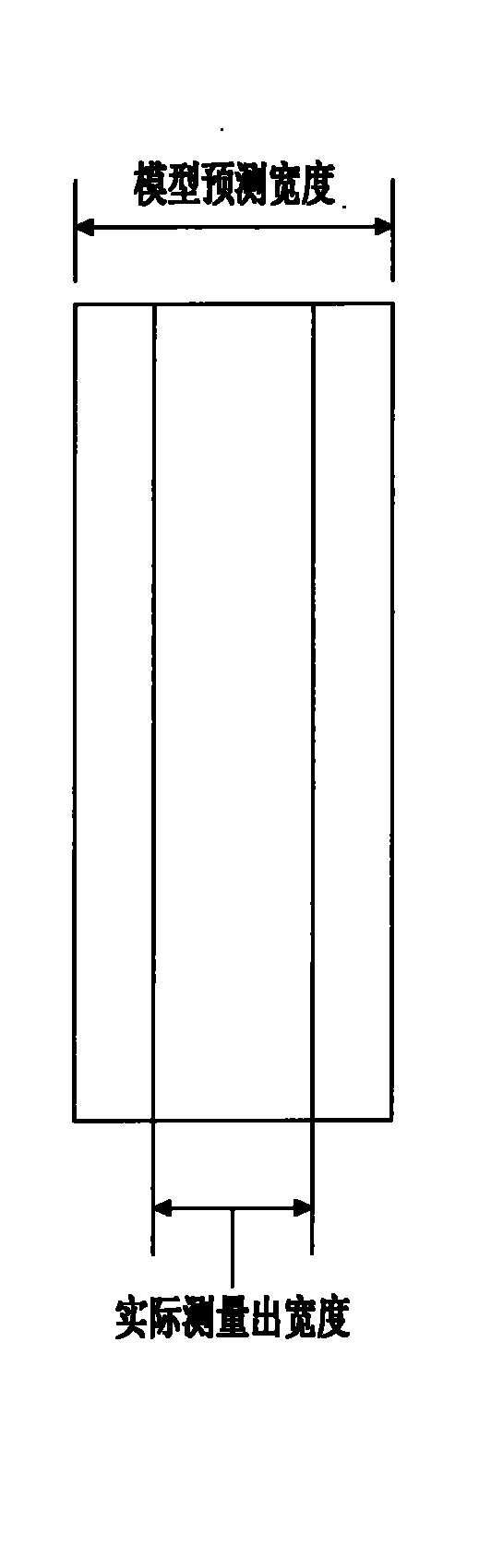

[0029] To produce 1200mm products, if the pre-calculated width of the incoming strip is greater than the actual measured width, such as image 3 as shown, image 3 If the model predicts that the width of the rolled strip is 1250mm, but the actual measurement result of the width measuring equipment in front of the horizontal rolling mill is 1200mm, it means that the predicted value of the model is greater than the actual measured value, which means that the actual strip is narrower than the expected strip.

[0030] If the width control method of the present invention is not adopted, the primary width control amount of the front width control equipment of the horizontal rolling mill is 50mm, and since the actual strip blank is 1200mm, the width of the intermediate product produced is 1150mm, and the width amount deviation is -50mm, exceeding the feedback adjustment range, causing the final product to fail.

[0031] According to the width control method of the present invention,...

Embodiment 2

[0033] When producing 1200mm products, if the pre-calculated width of the incoming material is smaller than the actual measured width, such as Figure 4 as shown, Figure 4 If the model predicts that the width of the rolled strip is 1200mm, but the actual measurement result of the width measuring equipment in front of the horizontal rolling mill is 1250mm, it means that the predicted value of the model is smaller than the actual measured value, which means that the actual strip is wider than the expected strip.

[0034]If the width control method of the present invention is not adopted, the primary width control amount of the front width control equipment of the horizontal rolling mill is 0mm, and since the actual strip blank is 1250mm, the width of the intermediate product produced is 1250mm, and the width amount deviation+50mm exceeds the feedback adjustment range, causing the final product to fail.

[0035] According to the width control method of the present invention, tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com