Patents

Literature

31results about How to "Improved Width Control Accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of using rough rolling inverse-pass vertical roll gap measurement for conducting plate blank width control

ActiveCN104209339AExact width dataImproved Width Control AccuracyMetal rolling stand detailsModel learningControl mode

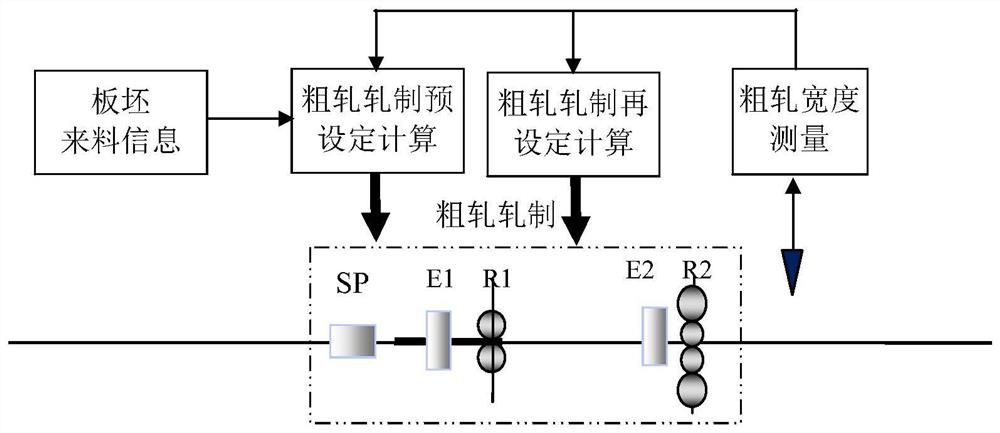

The invention provides a method of using rough rolling inverse-pass vertical roll gap measurement for conducting plate blank width control. A conventional rough rolling vertical roll inverse-pass rolling process is conducted in a dummied mode, and width control is not conducted on strip steel. According to the method, in the rough rolling inverse-pass rolling process, rolling is conducted on vertical rolls in a small rolling force control mode, roll gap measurement is conducted, and therefore plate blank width can be obtained through roll gap model calculation; the plate blank width is used for rough rolling width resetting and broadsiding model learning. The method can solve the problem that accurate width measurement data can not be obtained in pony-roughing pass rough rolling process in the prior art, accurately provide plant blank inlet width used for resetting calculation in the rough rolling process, and improve the final rough rolling precision.

Owner:BAOSHAN IRON & STEEL CO LTD

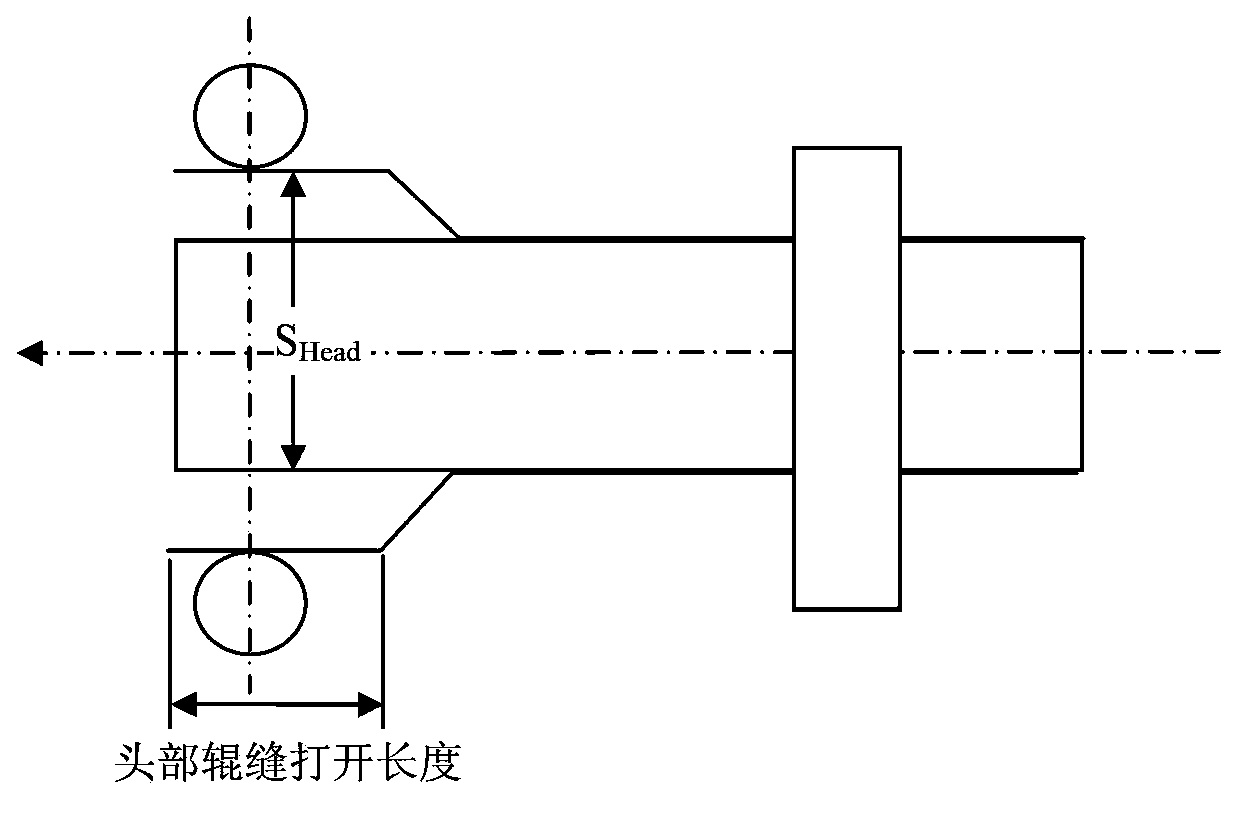

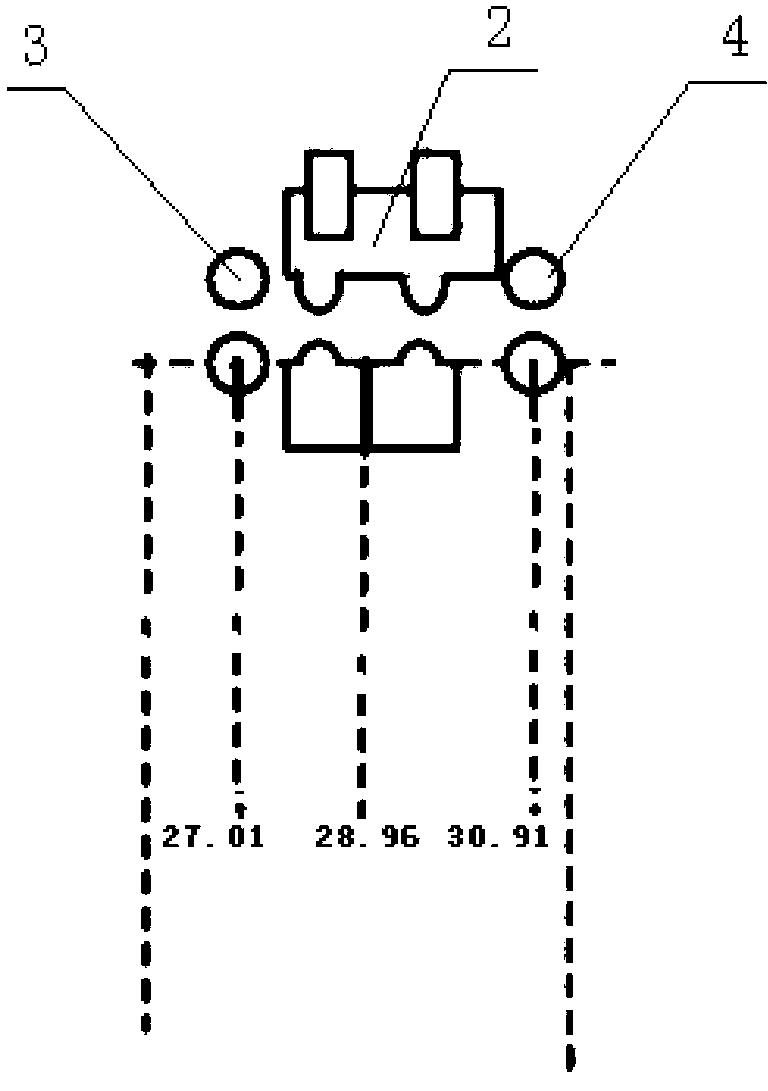

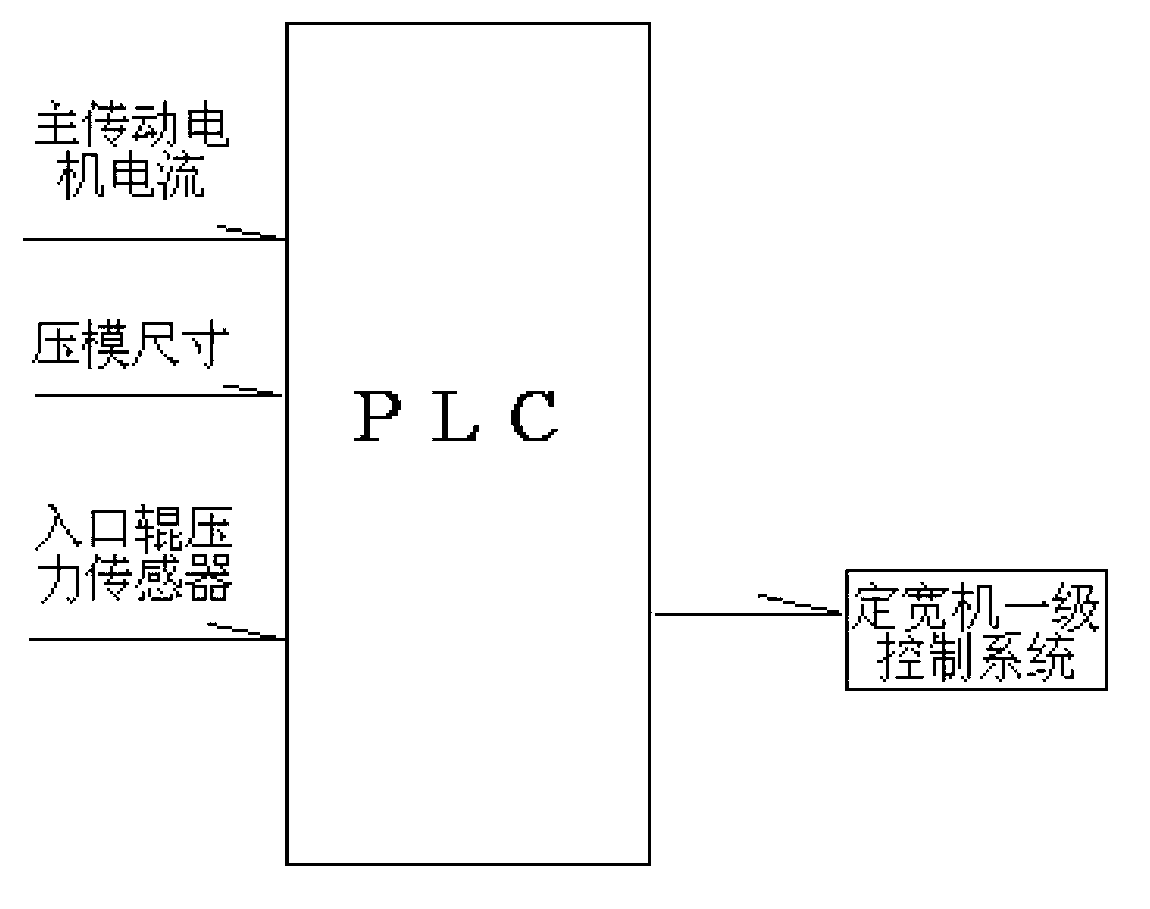

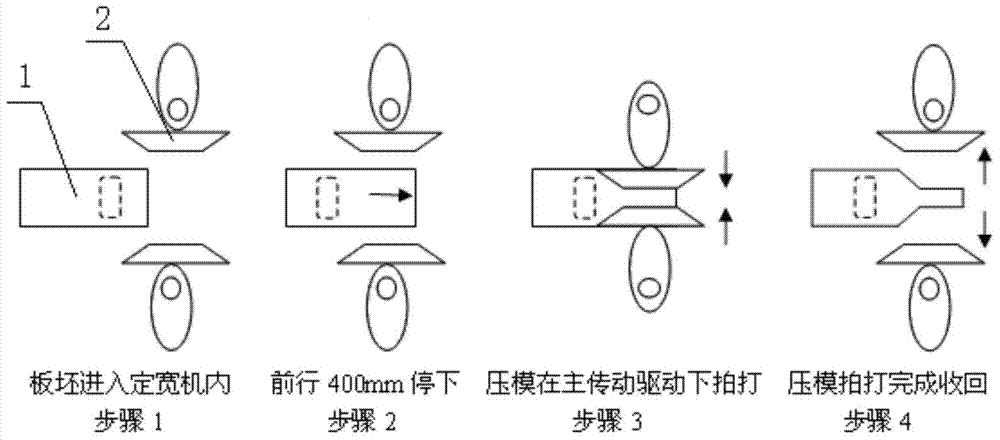

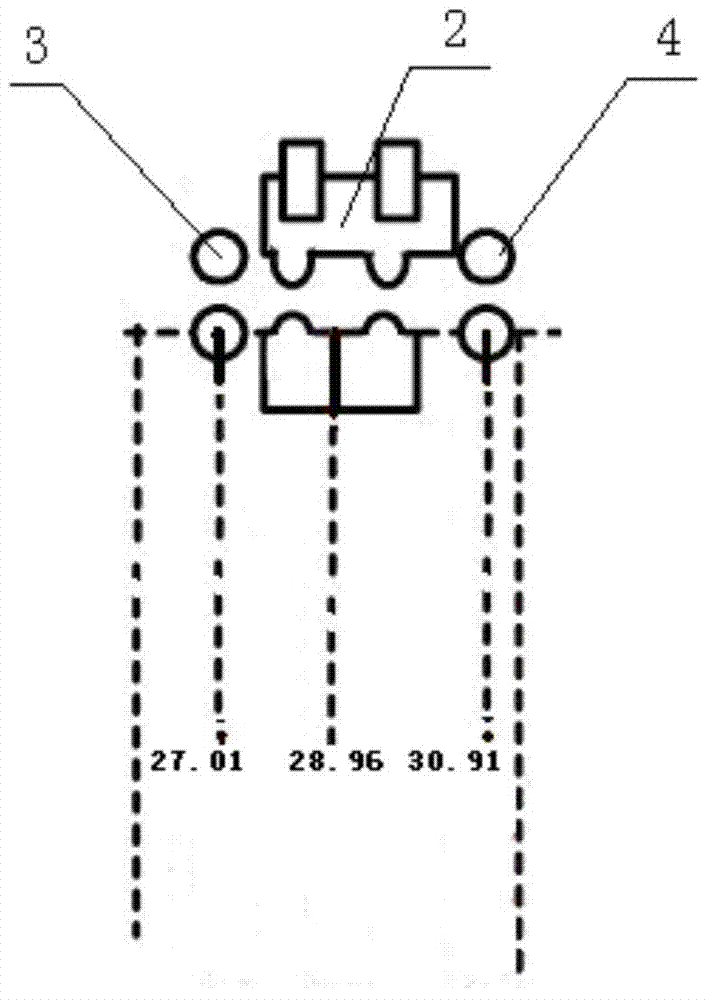

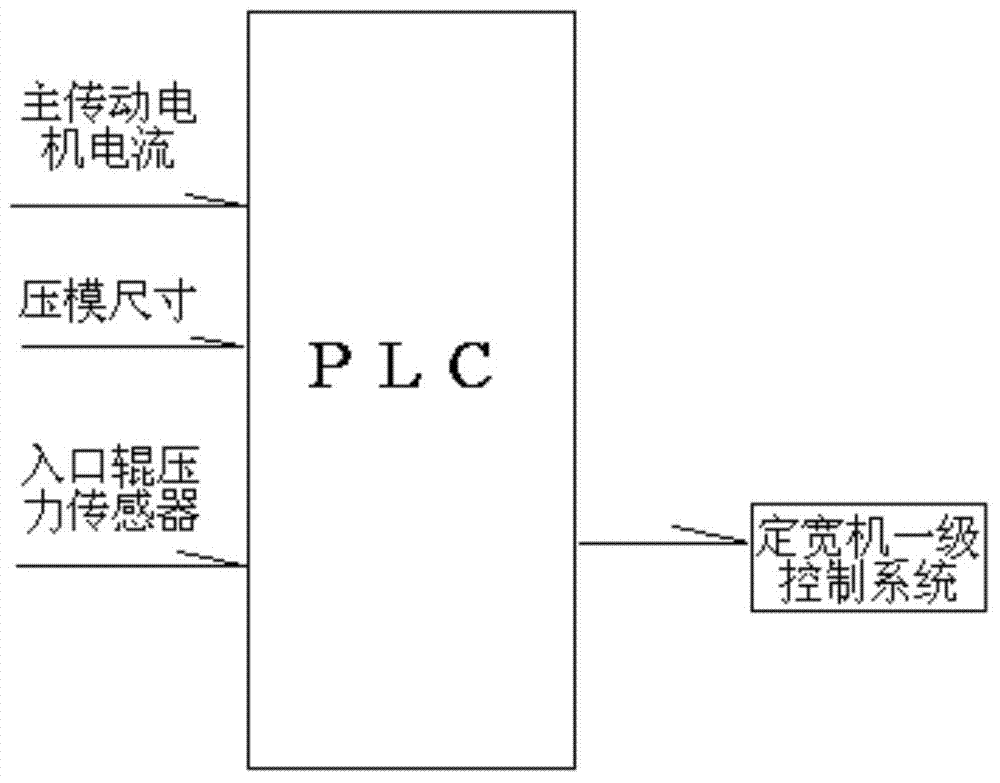

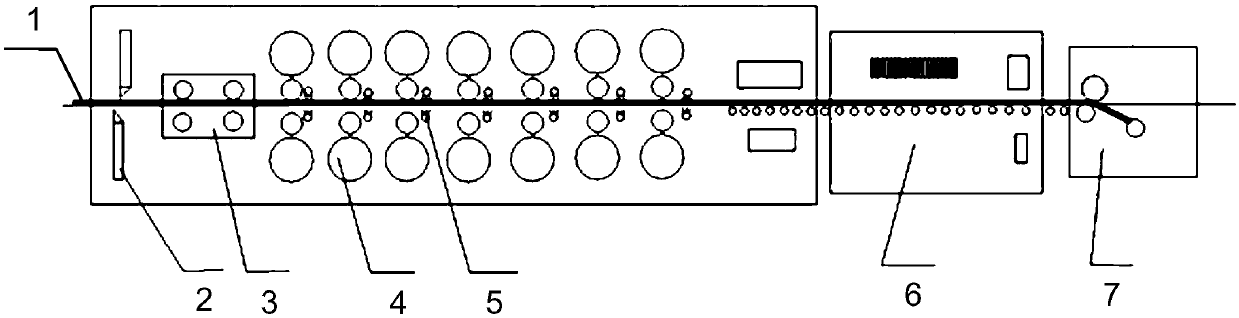

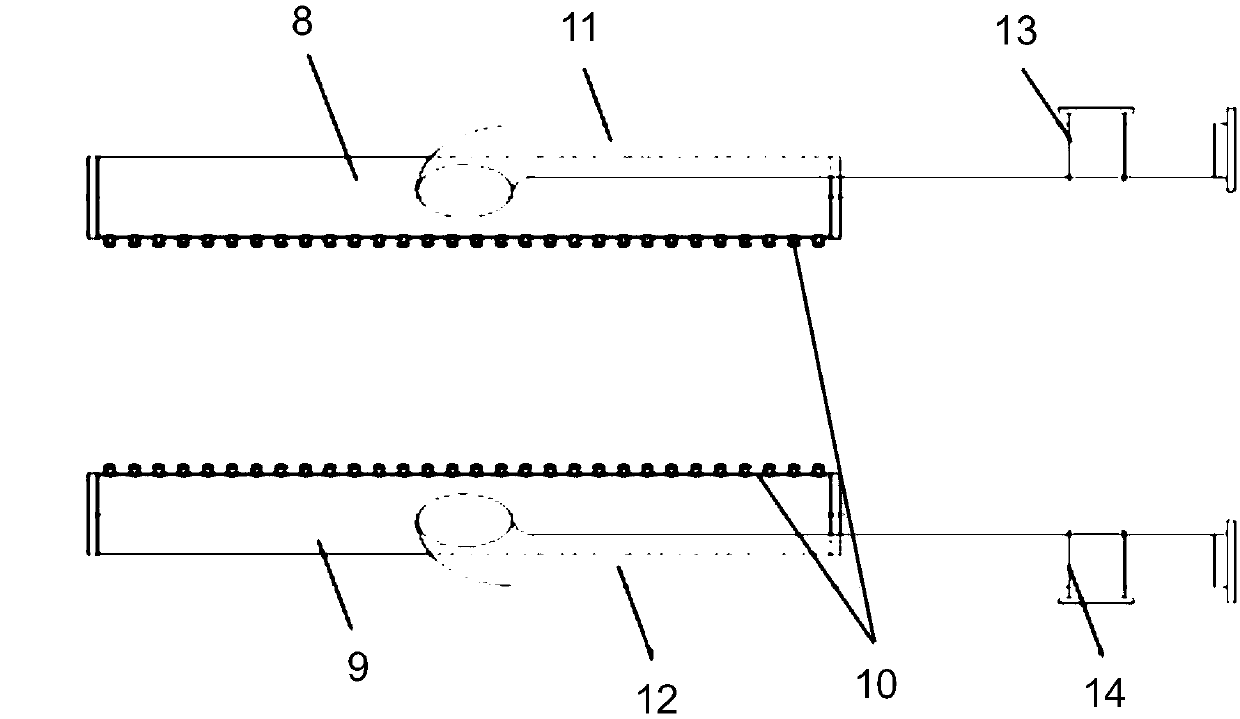

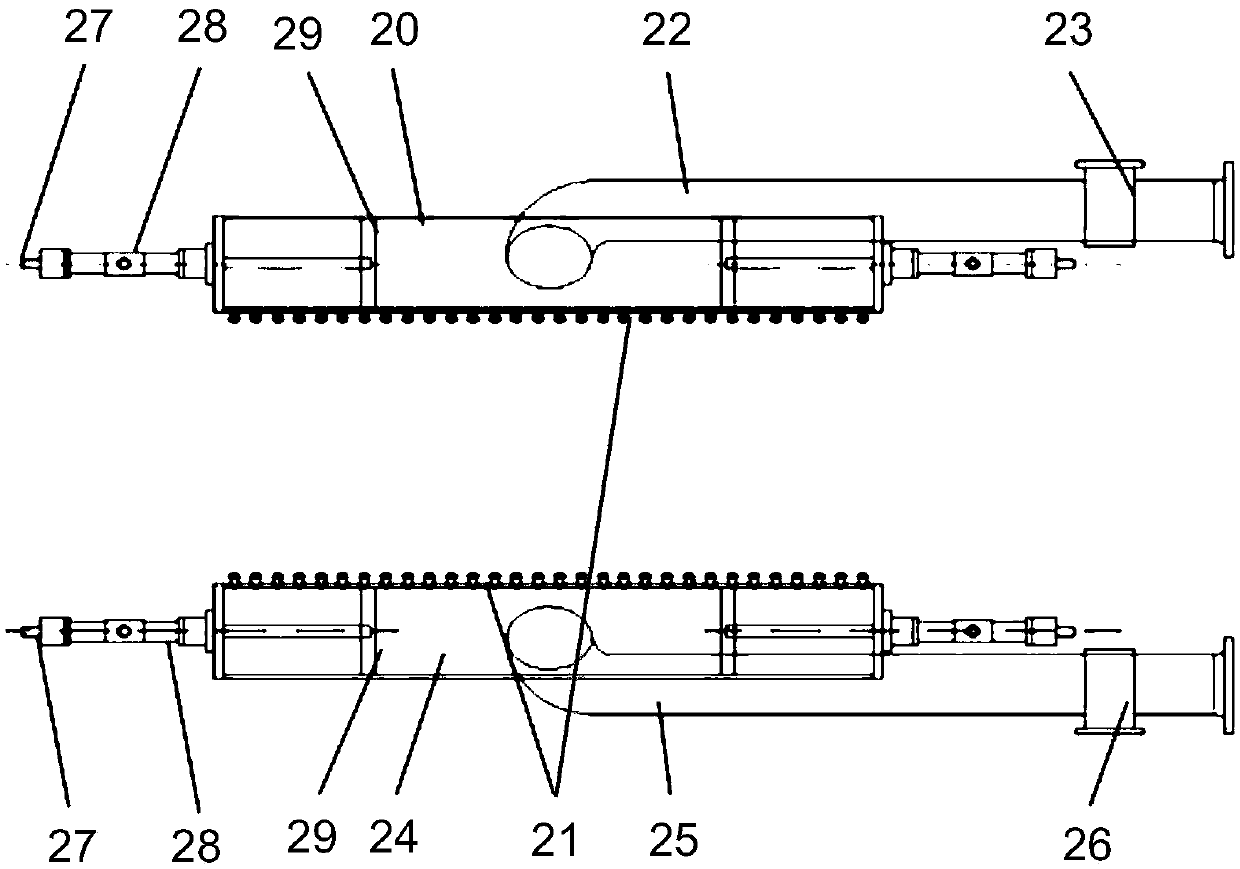

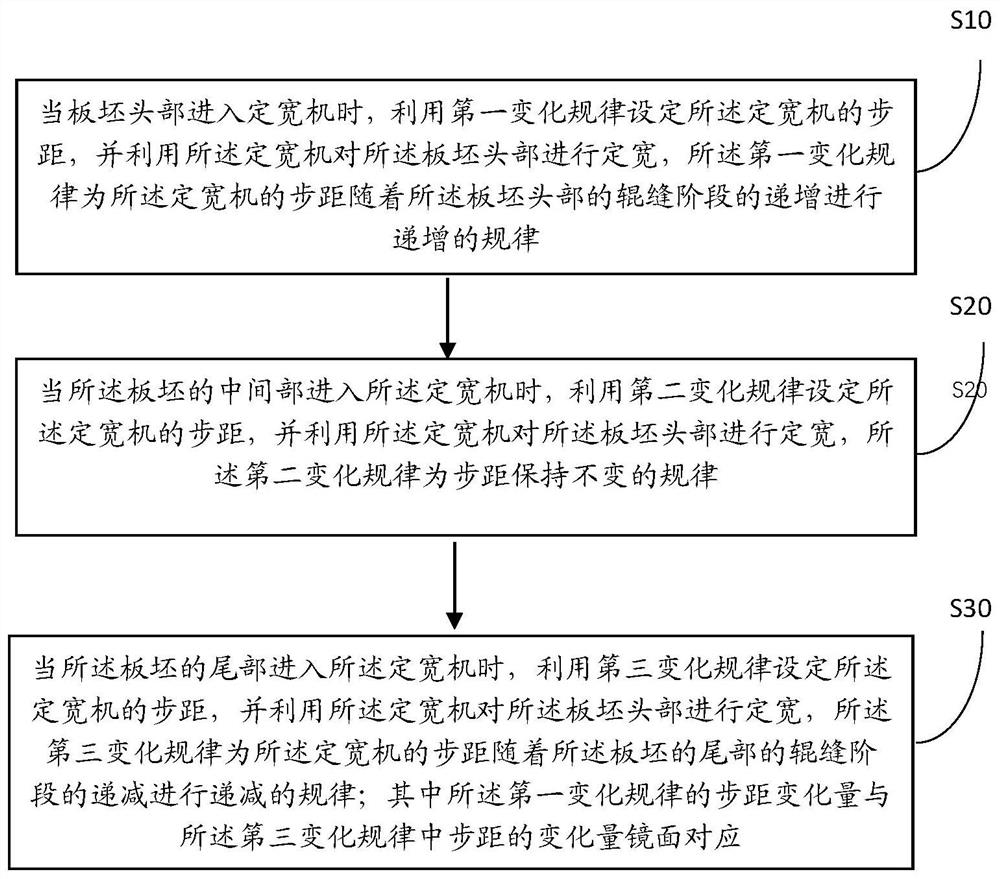

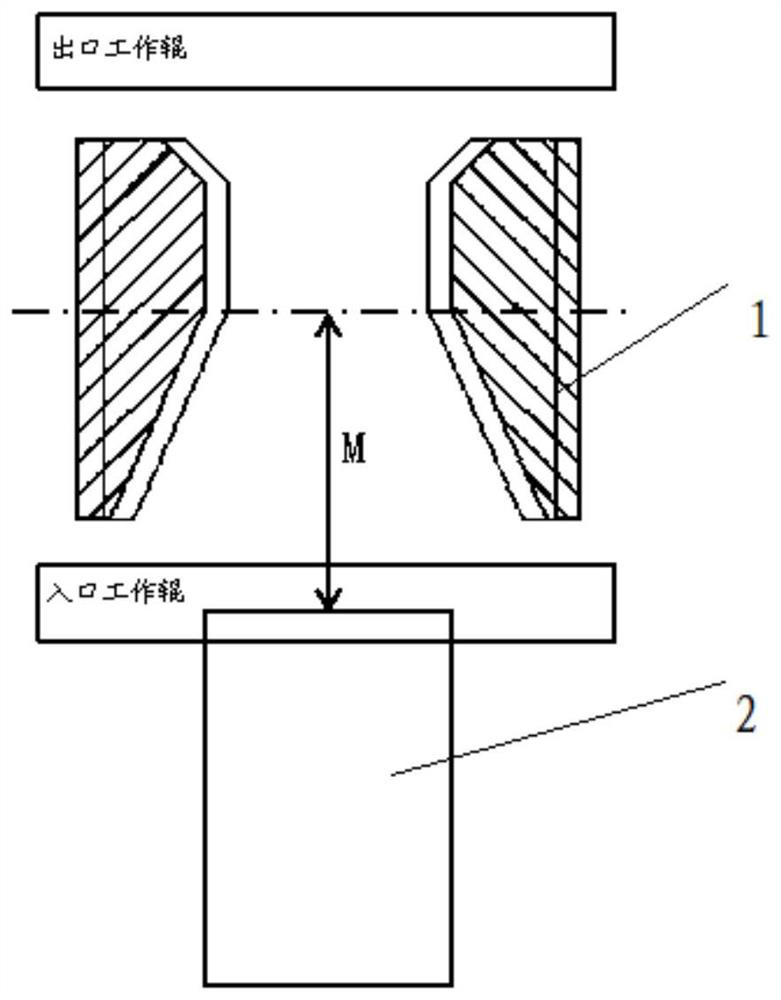

Device for tracing and detecting interior plate blank head position of fixed width machine

InactiveCN103341499AIncreased rolling timeDecreased width control accuracyRoll mill control devicesMetal rolling arrangementsMachine controlPower flow

The invention provides a device for tracing and detecting an interior plate blank head position of a fixed width machine. The device for tracing and detecting the interior the plate blank head position of the fixed width machine comprises a fixed width machine control PLC and a fixed width machine first-level control system connected with the fixed width machine control PLC; the input end of the fixed width machine control PLC is connected with a main transmission motor current signal, a pressing die size, and an inlet pinch roller pressure signal. The fixed width machine control PLC comprises a filtering module, a counting module, a plate blank head position calculating module and a communication module; filter shaping is conducted on the main transmission motor signal by the filtering module; the number of impulses of the main transmission motor current signal is accumulated by the counting module; the plate blank head position is calculated by the plate blank head position counting module, and the calculation formula is a plate blank head position value=28.96m+the number of the impulses of the main transmission motor current signal*the pressing die size; the plate blank head position value is transmitted to the fixed width machine first-level control system in real time by the communication module; the filtering module judges monitored currents, and the impulses are effective when the currents are larger than or equal to 4000A every time.

Owner:武汉钢铁有限公司

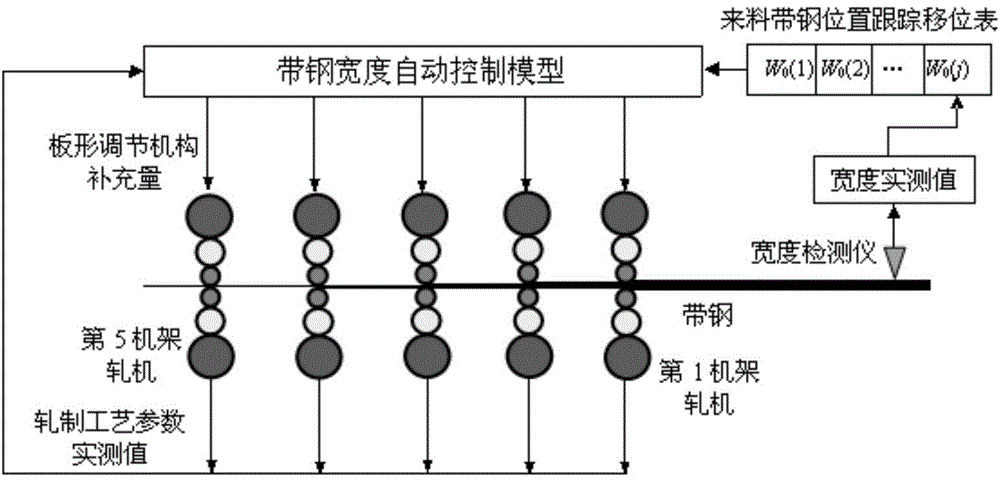

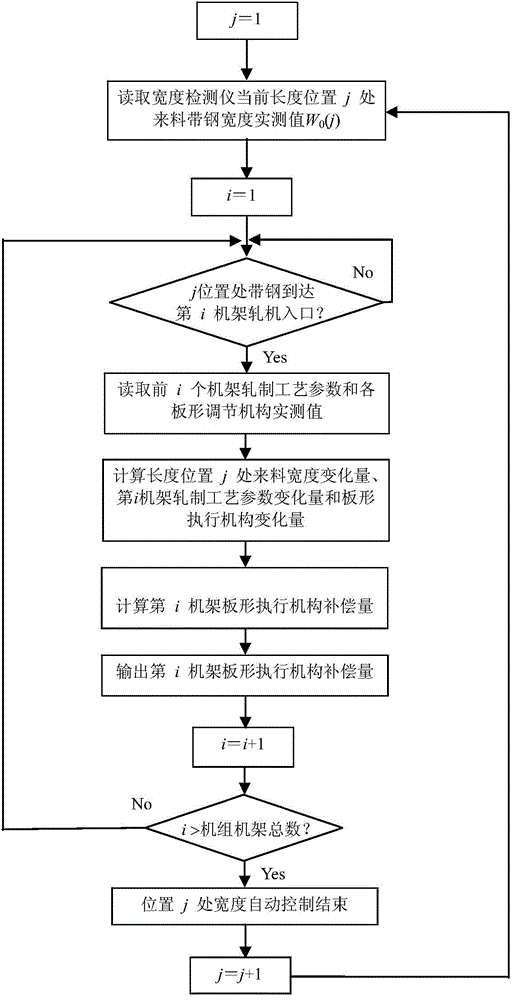

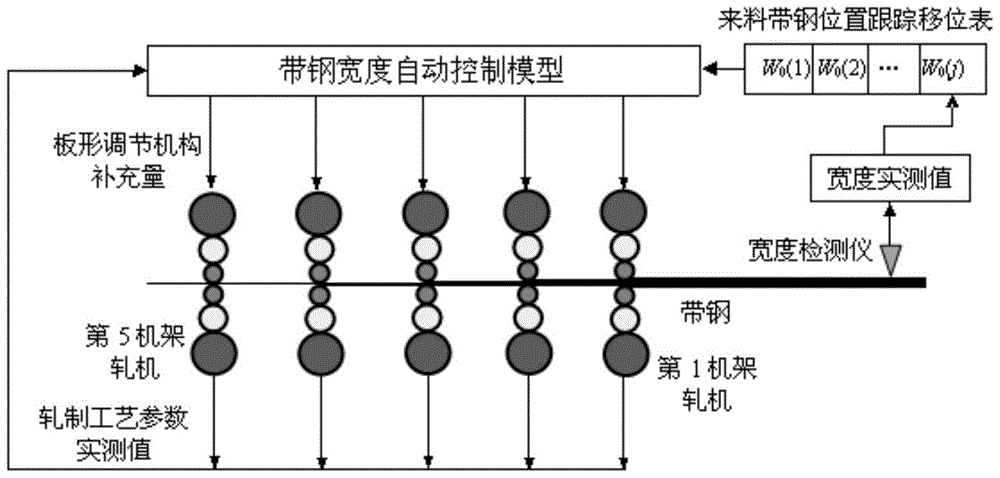

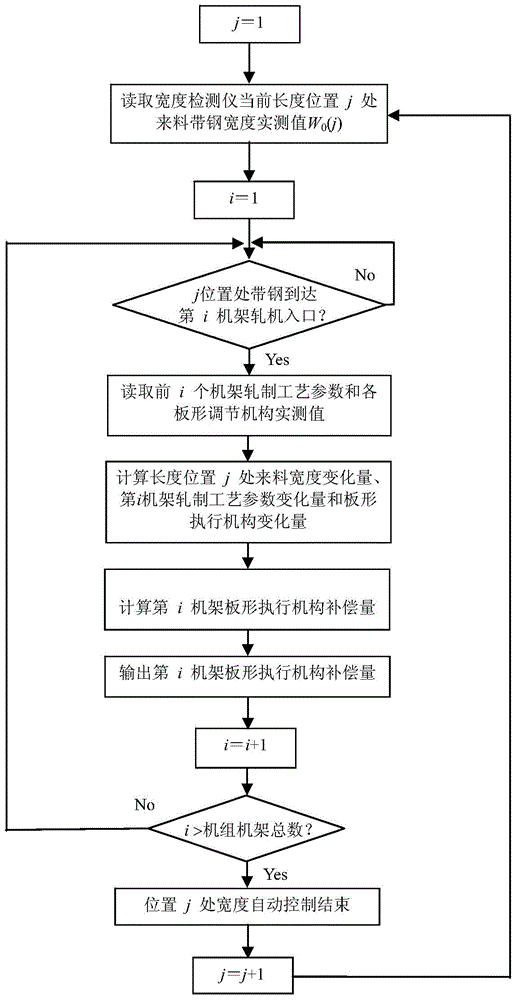

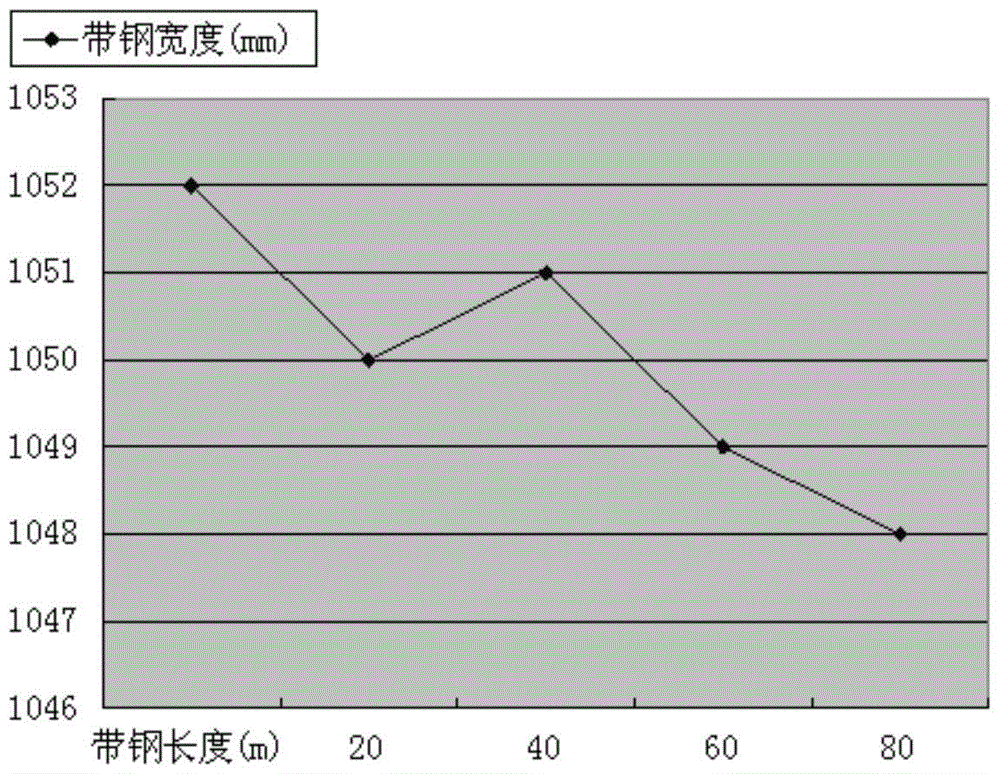

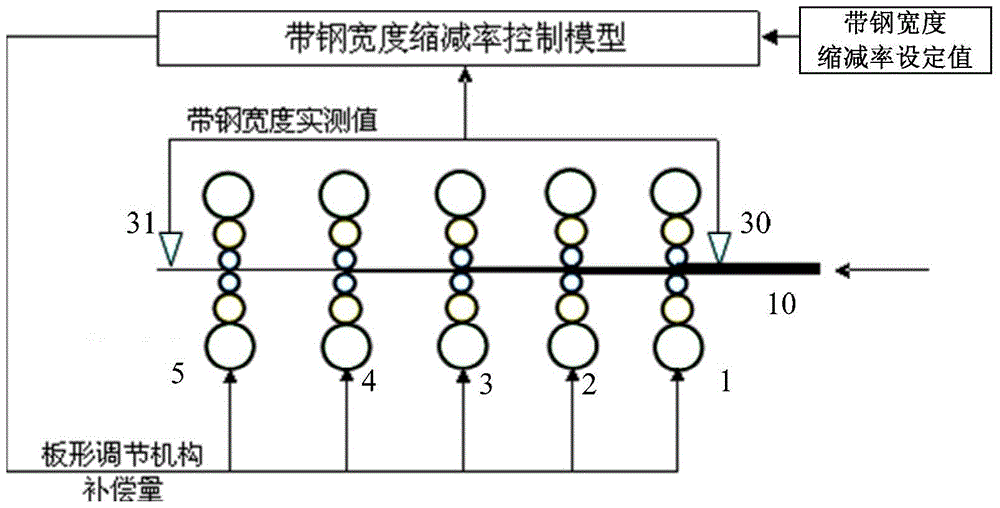

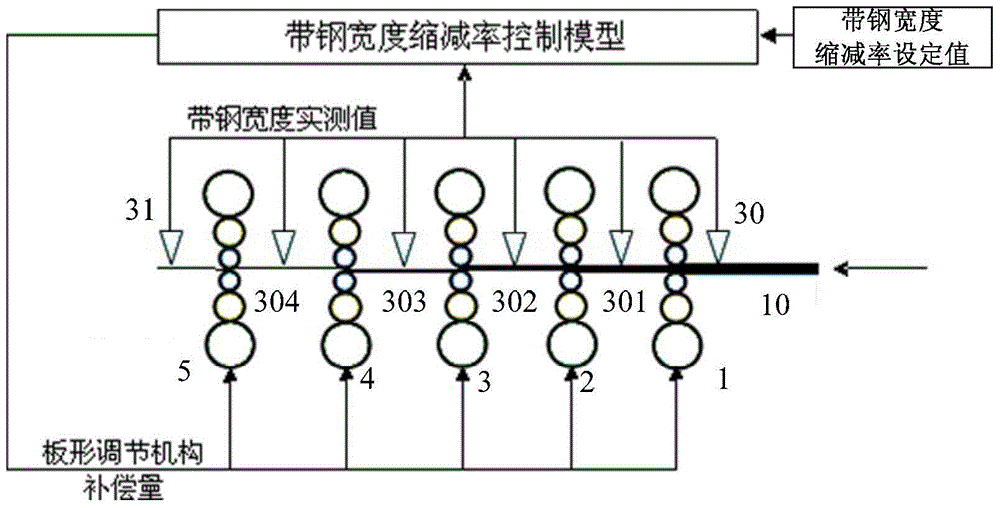

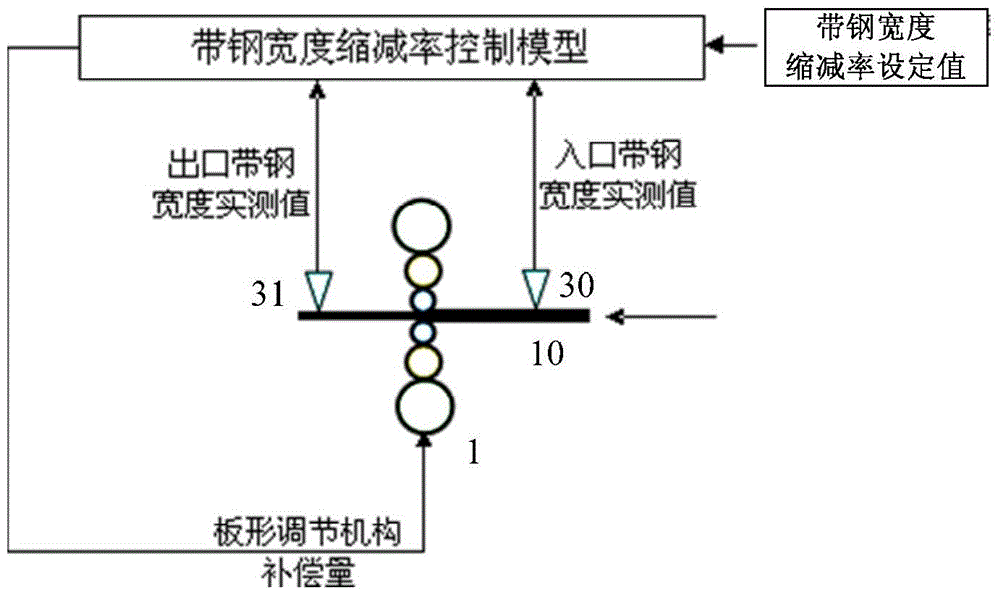

Automatic control method for width of steel strips during cold rolling

ActiveCN104942019ASmall sectionImprove stabilityMetal rolling stand detailsRoll mill control devicesAutomatic controlHot rolled

The invention relates to an automatic control method for width of steel strips during cold rolling, and belongs to the technical field of automatic control. The method includes: establishing forecasting models for width of exit steel strips for each stand; detecting width measured value at each position in the longitudinal direction of hot-rolled steel strips from an entry of a cold rolling unit in real time; calculating the differences between the measured values and preset values of width of the hot-rolled steel strips, and obtaining width variation of the hot-rolled steel strips to be eliminated by each stand; performing length position tracking on the hot-rolled steel strips from the entry of the cold rolling unit to obtain predicted values of exit width variation of the unit; determining real-time compensation of plate-shaped regulating mechanism of the No. m stand by changing compensation value of the plate-shaped regulating mechanism of a rolling mill of the stand in real time; according to the real time compensation of the plate-shaped regulating mechanism of each stand, performing feedforward control for exit width of each stand, and timely eliminating fluctuation of the width of the hot-rolled steel strips and influence on width of exit steel strips at the last stand by rolling technology parameter variation of each stand to improve width control precision of cold-rolled steel strips and stability of cold-rolling production process.

Owner:BAOSHAN IRON & STEEL CO LTD

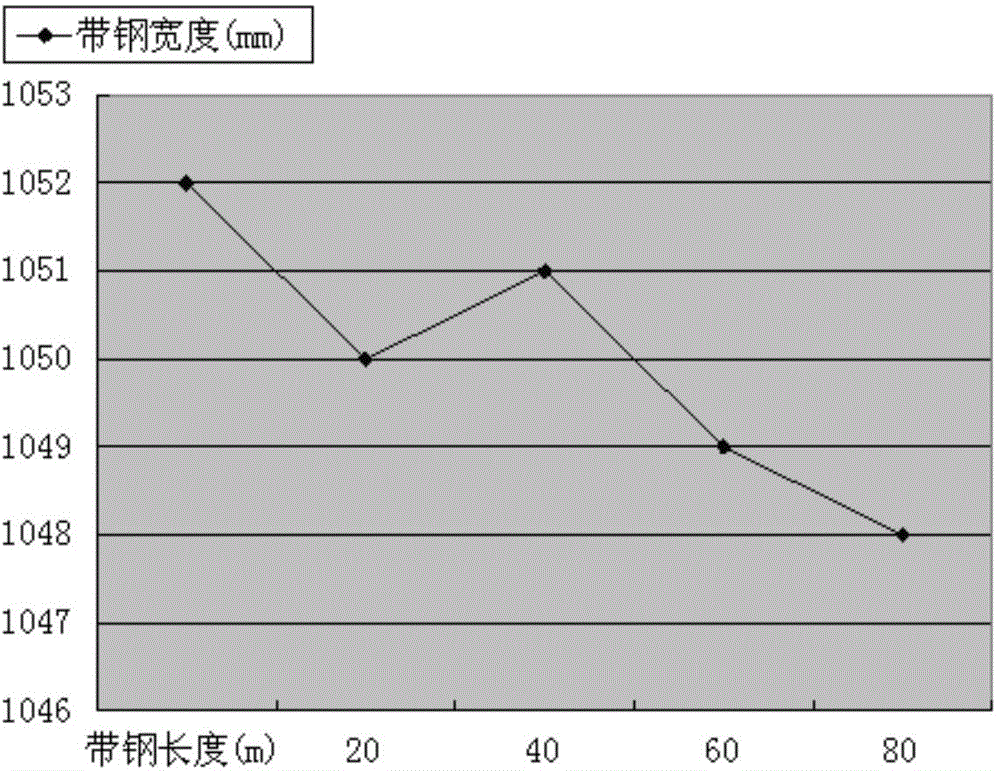

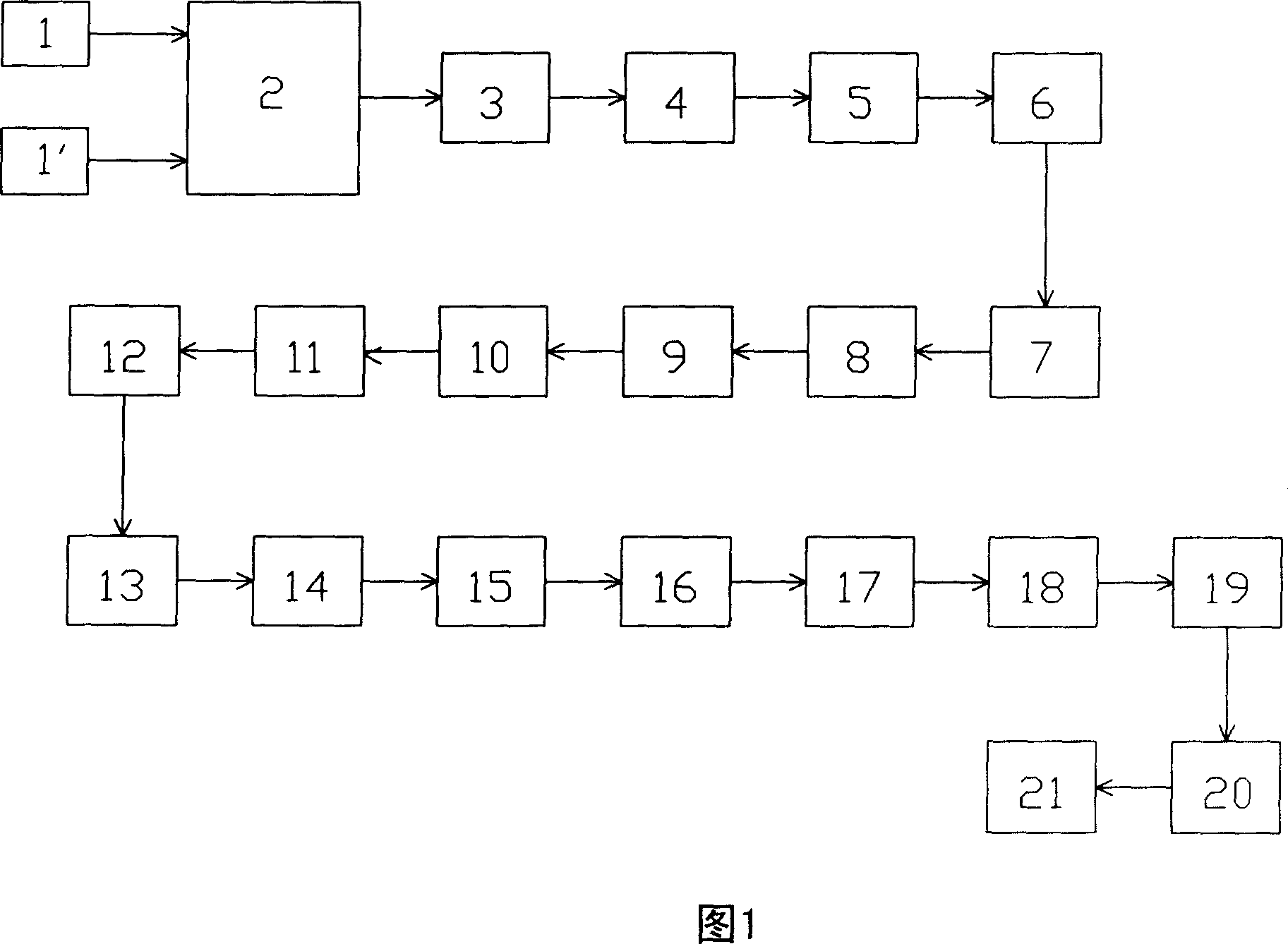

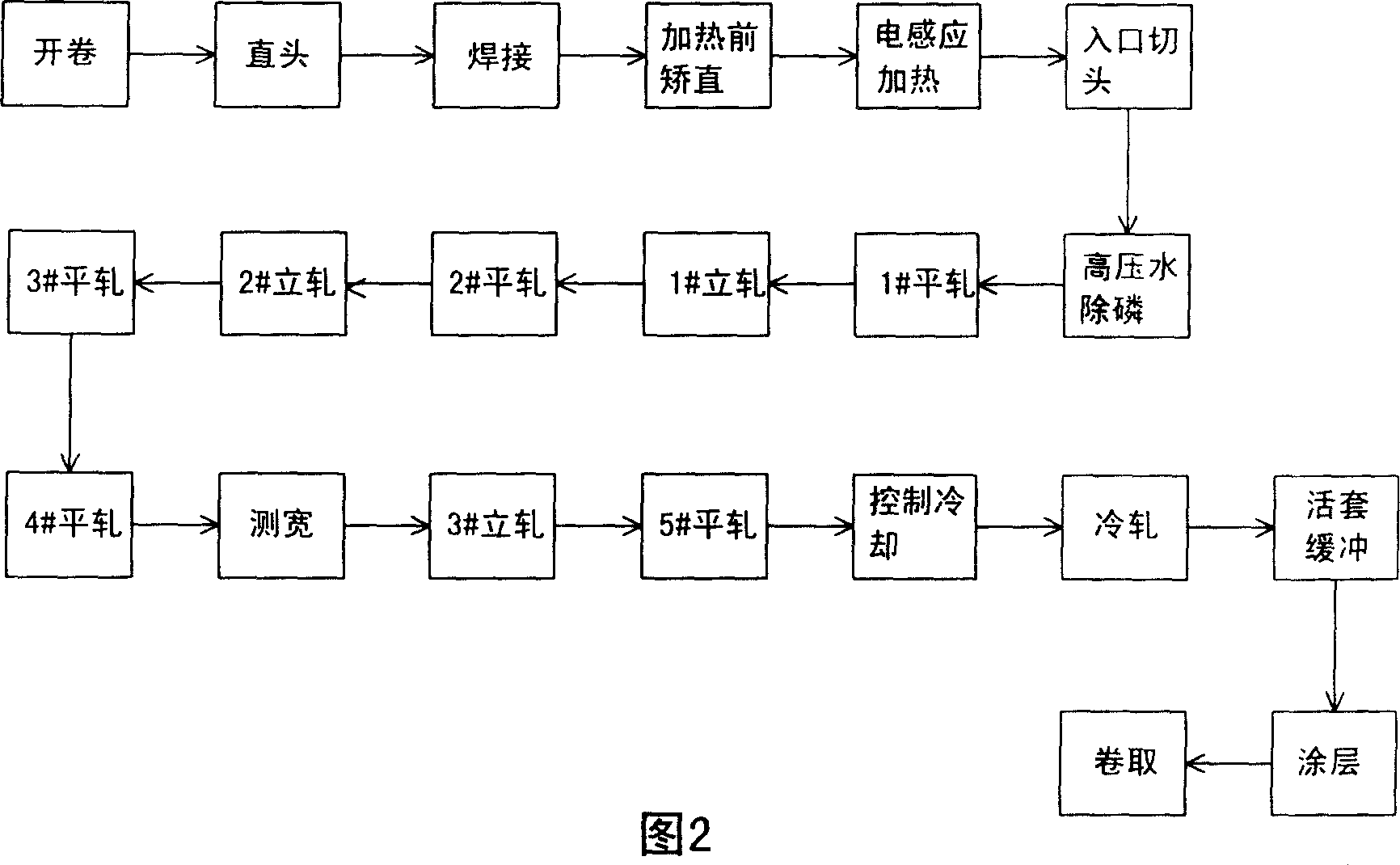

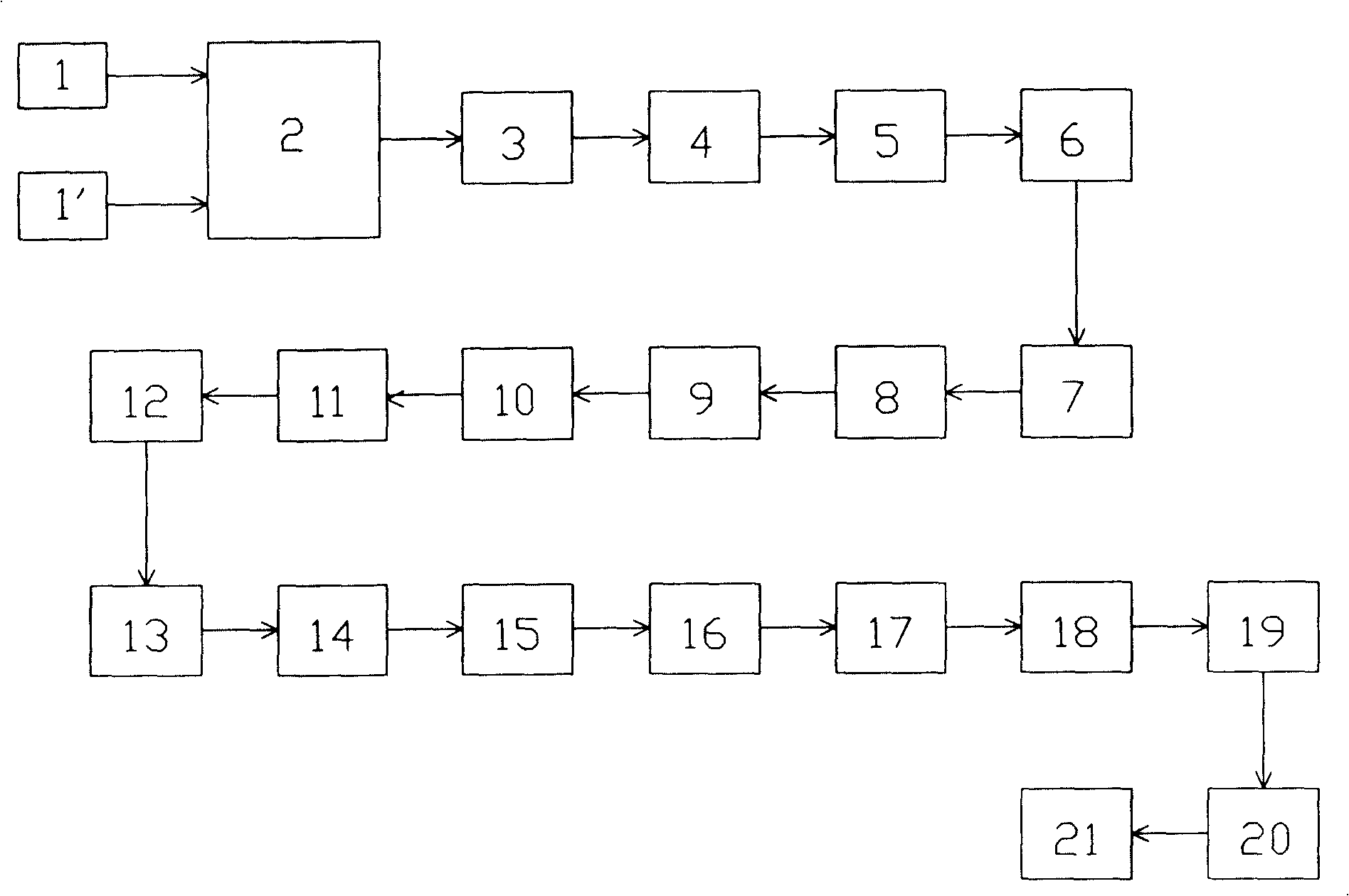

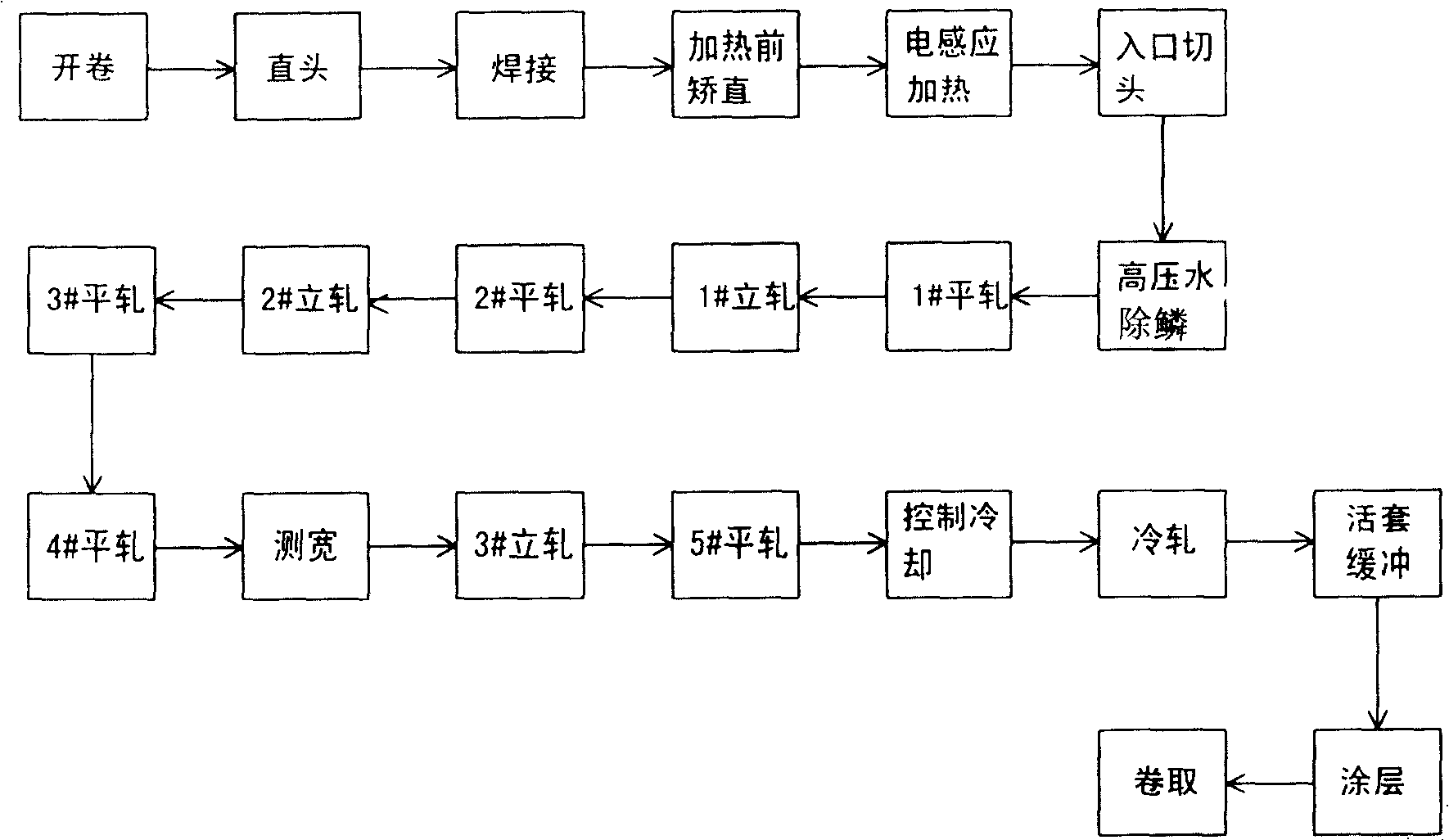

Production facility and method for high-intensity packing steel belt

InactiveCN1927482ARounded cornersHigh elongationWork treatment devicesMetal rolling arrangementsPhosphorHigh pressure water

The invention relates to a method for producing high-strength packing steel band. Wherein, the inventive device comprises material preparer, induction heating furnace, end cutter, high-pressure water dephosphorize device, eight thermal rollers, one cold roller, middle cooling section, wide closed controller, thickness closed controller, movable sleeve, coater, and coiler; and the method comprises: preparing materials, induced heating, cutting end, removing phosphor, thermally rolling, controlling width, cooling, cold rolling, coating, coiling, while it can add welder and additive heater. In the production, the temperature of heating furnace should be controlled accurately, and the cooling speed should be controlled. The inventive steel band has high quality while the width accuracy is 0-1mm, and its cost is low.

Owner:鞍山众鼎科技有限公司

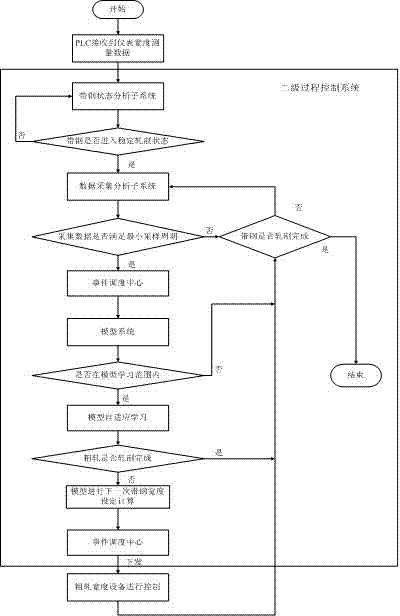

Hot rolling width model fast dynamic self-adapting method

ActiveCN104707869AMaximum sizeSmall deviation from the minimumMetal rolling stand detailsRoll mill control devicesAdaptive learningDynamic learning

The invention relates to a hot rolling width model fast dynamic self-adapting method. According to the main control principle of the hot rolling width model fast dynamic self-adapting method, the model leaning strategy is changed, the data collecting method is improved, one time of model self-adapting leaning is conducted through width detecting equipment needed the overall pass through of a strip steel formerly, and the methods that leaning is conducted when part of the strip steel passes through the width detecting equipment, and repeatedly dynamic learning strategy is possessed are replaced. The hot rolling width model fast dynamic self-adapting method have the advantages that the problems that the width self-adapting correction is lagged in real production control, the phenomenon of width over-control occurs, and the width control deviation occurs in high-speed rolling pacing are solved, and the subsequent strip steel control precision is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

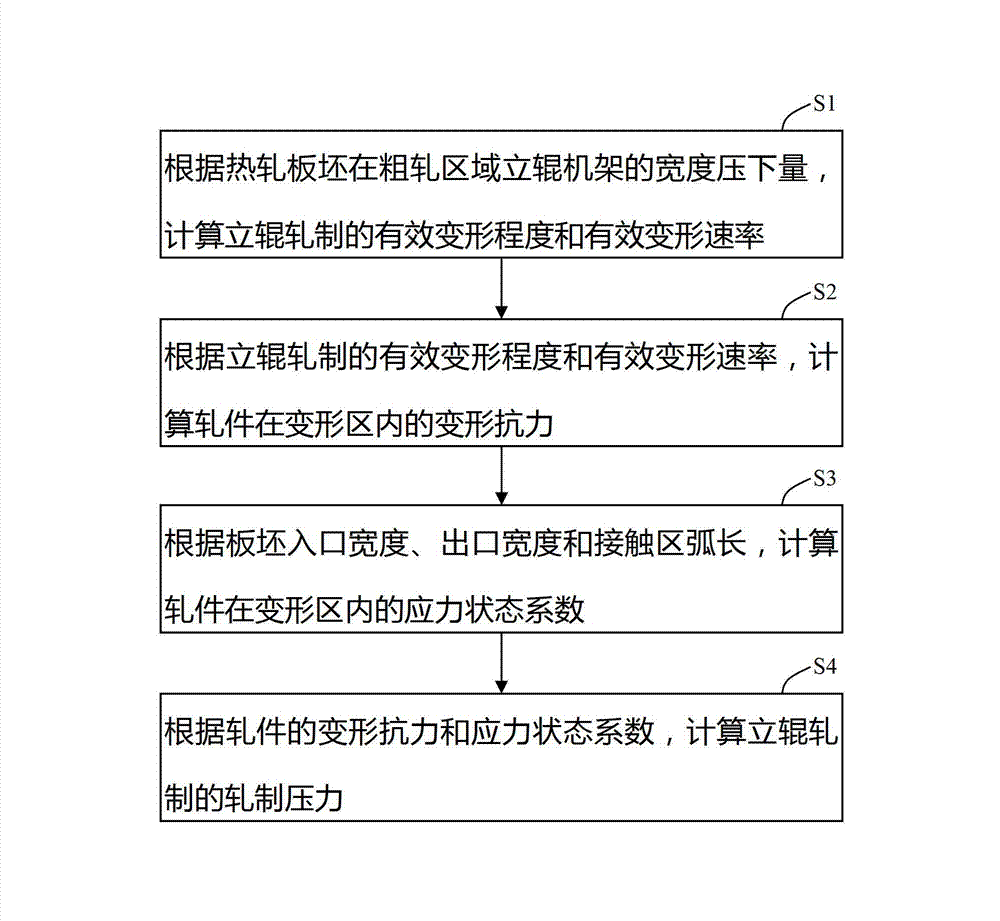

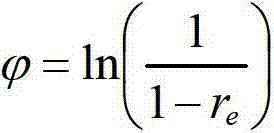

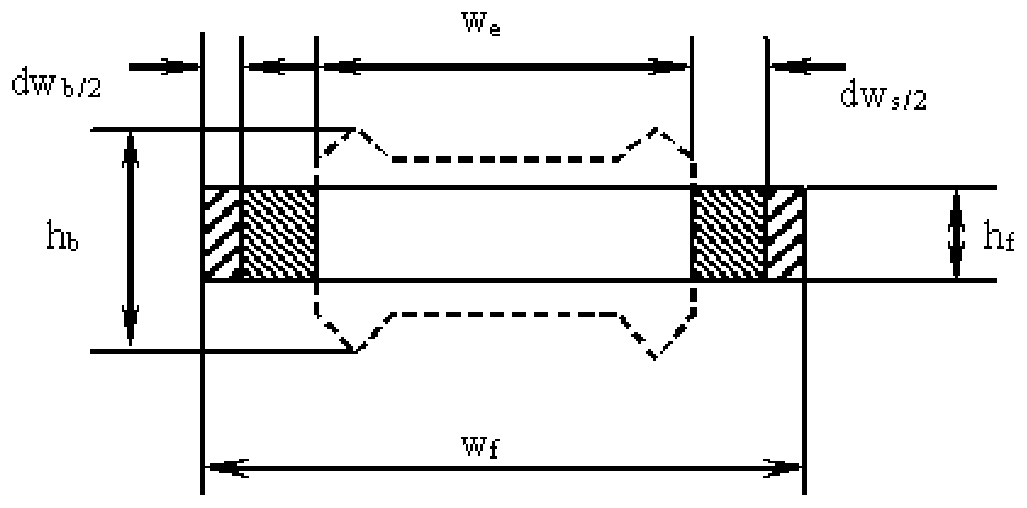

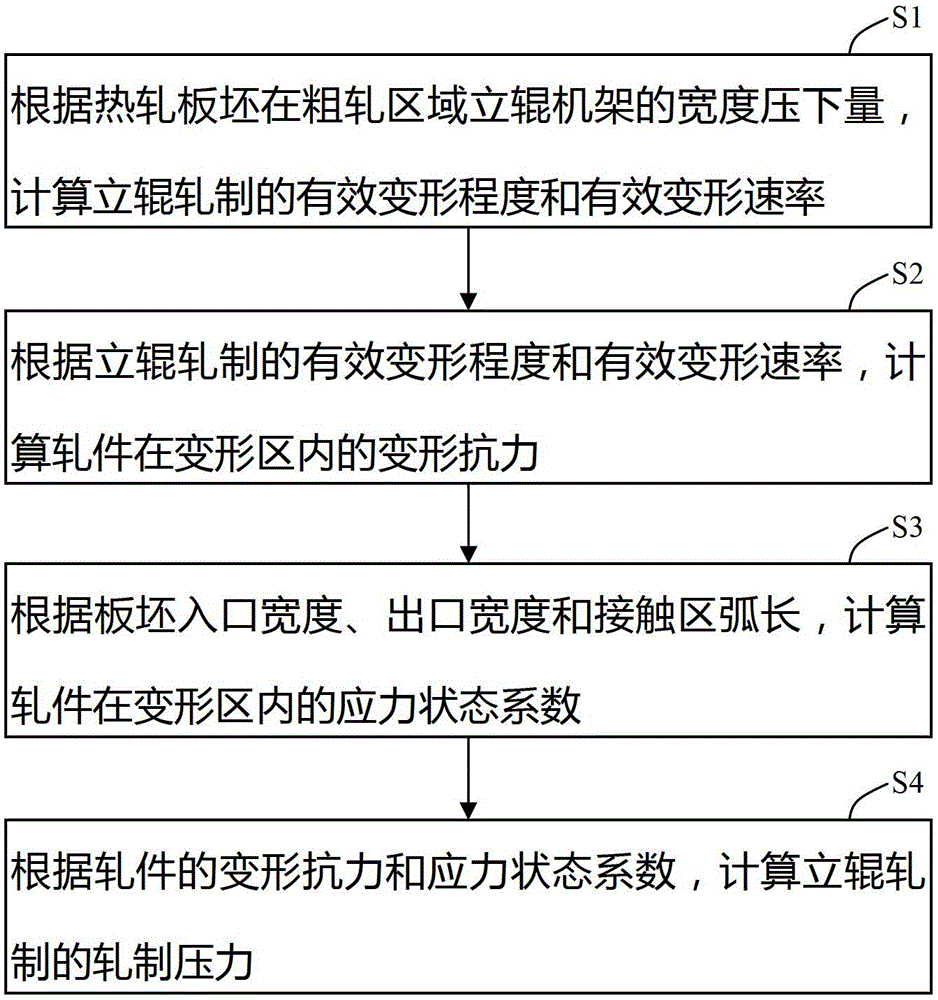

Method for setting rolling pressure of hot continuous rough rolling area during rolling by aid of vertical rolls

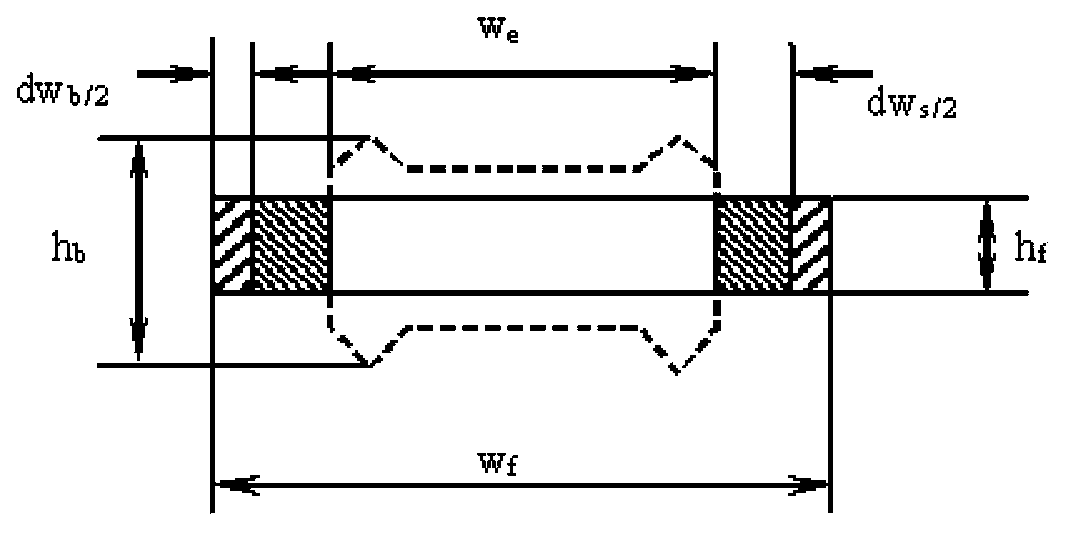

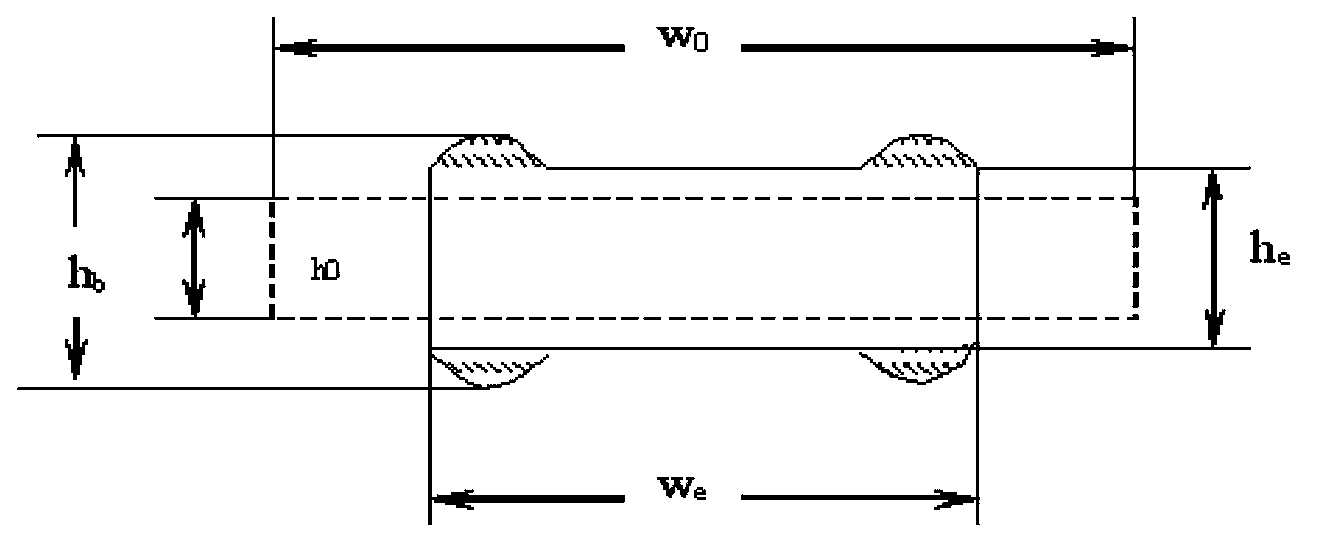

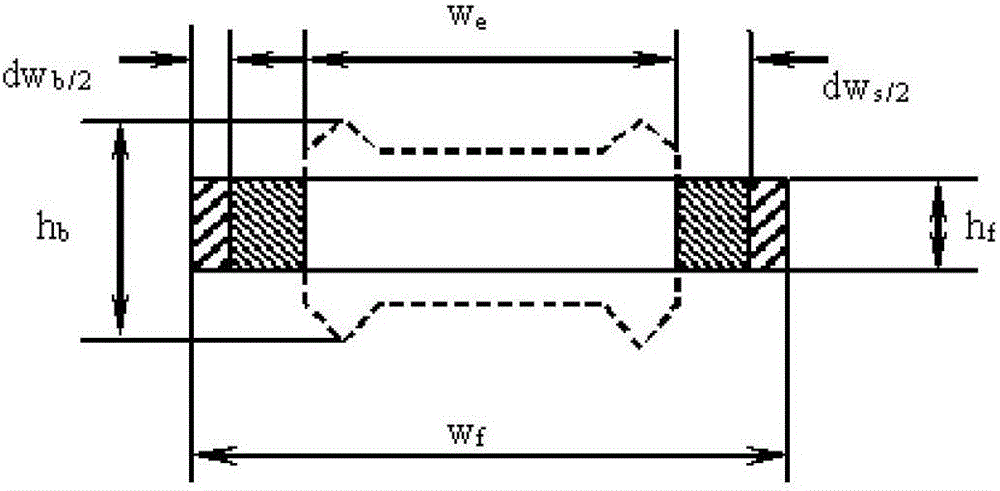

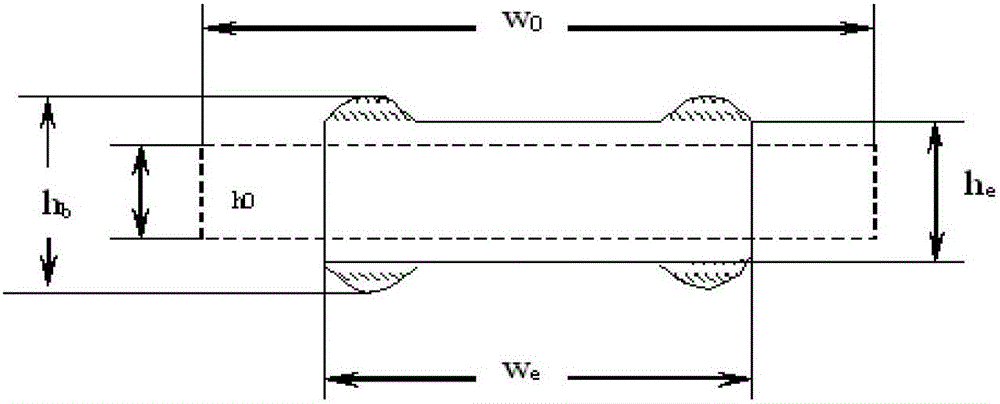

ActiveCN103586289AImprove rolling pressure setting accuracyImproved Width Control AccuracyTension/compression control deviceStrip steelStressed state

The invention discloses a method for setting rolling pressure of a hot continuous rough rolling area during rolling by the aid of vertical rolls. The method includes steps of firstly, computing an effective deformation degree and an effective deformation rate during rolling by the aid of the vertical rolls according to width rolling reduction of a hot-rolled plate blank on a vertical roll framework in the rough rolling area; secondly, computing deformation resistance of a rolled piece in a deformation area according to the effective deformation degree and the effective deformation rate which are obtained in the first step; thirdly, computing stress state coefficients of the rolled piece in the deformation area according to the width of a plate blank inlet, the width of an outlet and an arc length of a contact area; fourthly, computing the rolling pressure during rolling by the aid of the vertical rolls according to the deformation resistance obtained in the second step and the stress state coefficients obtained in the third step. The method for setting the rolling pressure of the hot continuous rough rolling area during rolling by the aid of the vertical rolls has the advantages that the rolling pressure setting precision of the rough rolling area during rolling by the aid of the vertical rolls can be improved, and accordingly the strip steel width control precision can be enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

Computer model control method for thickness of hot-rolled product

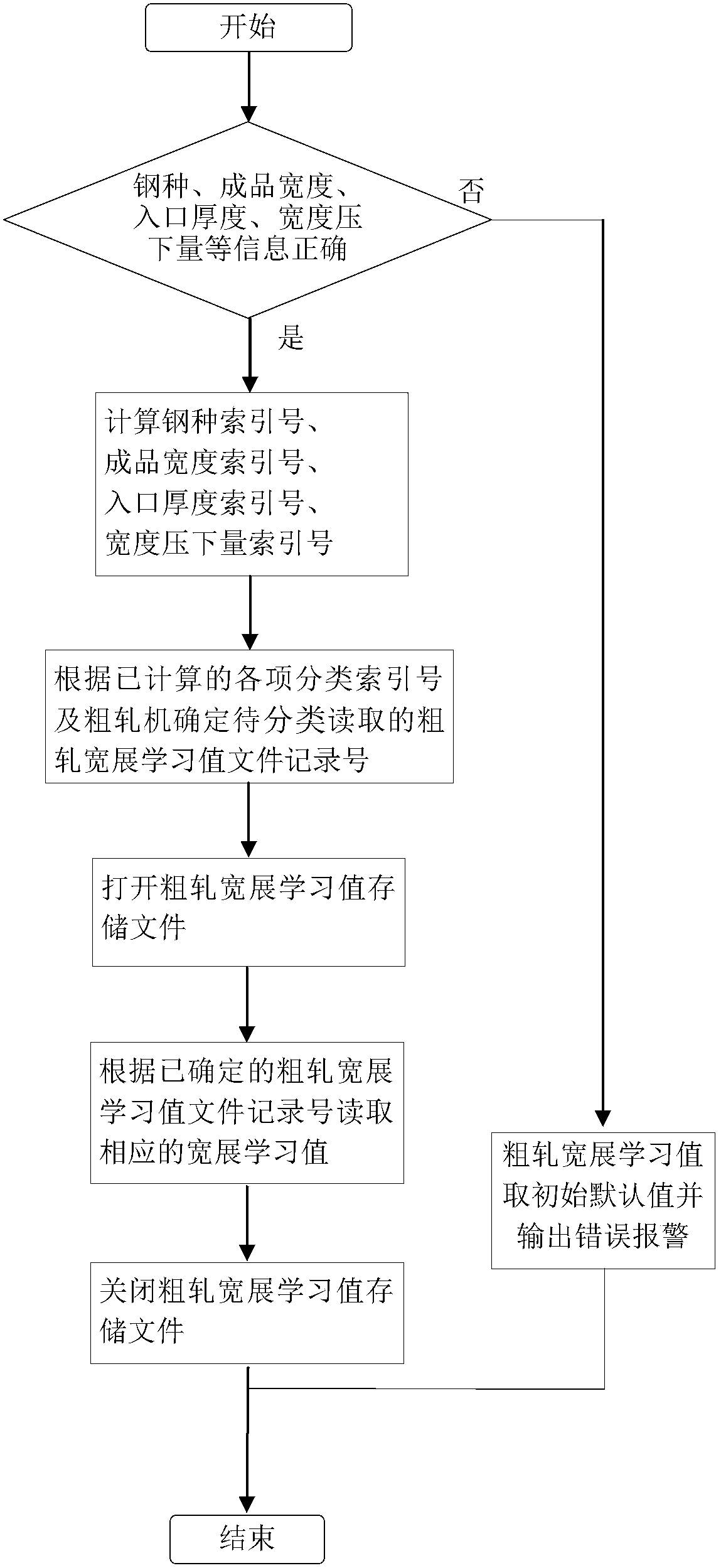

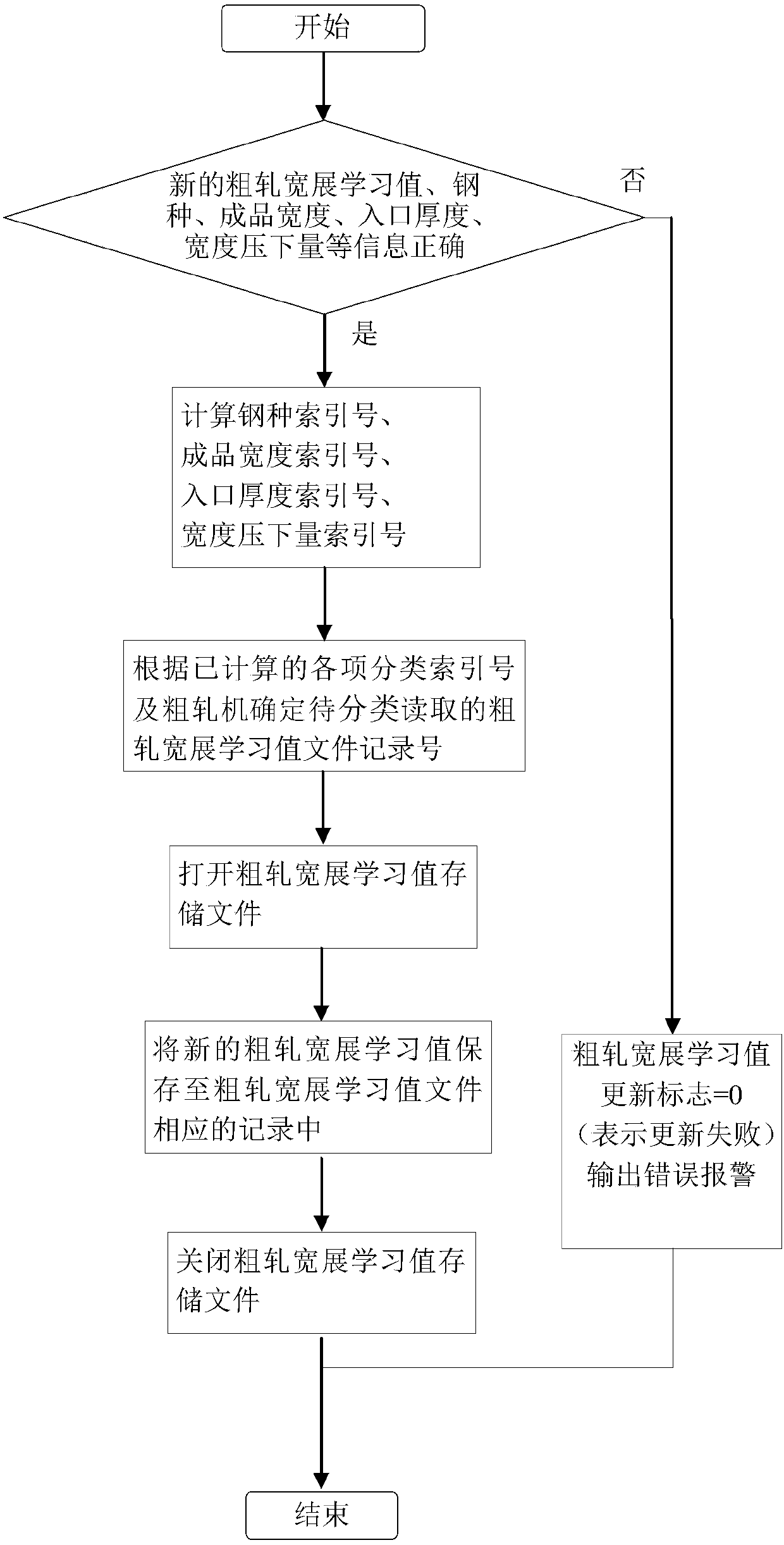

ActiveCN107626748ANarrowing the volatility rangeReduce resection rateMetal rolling stand detailsRoll mill control devicesClassification methodsWaste product

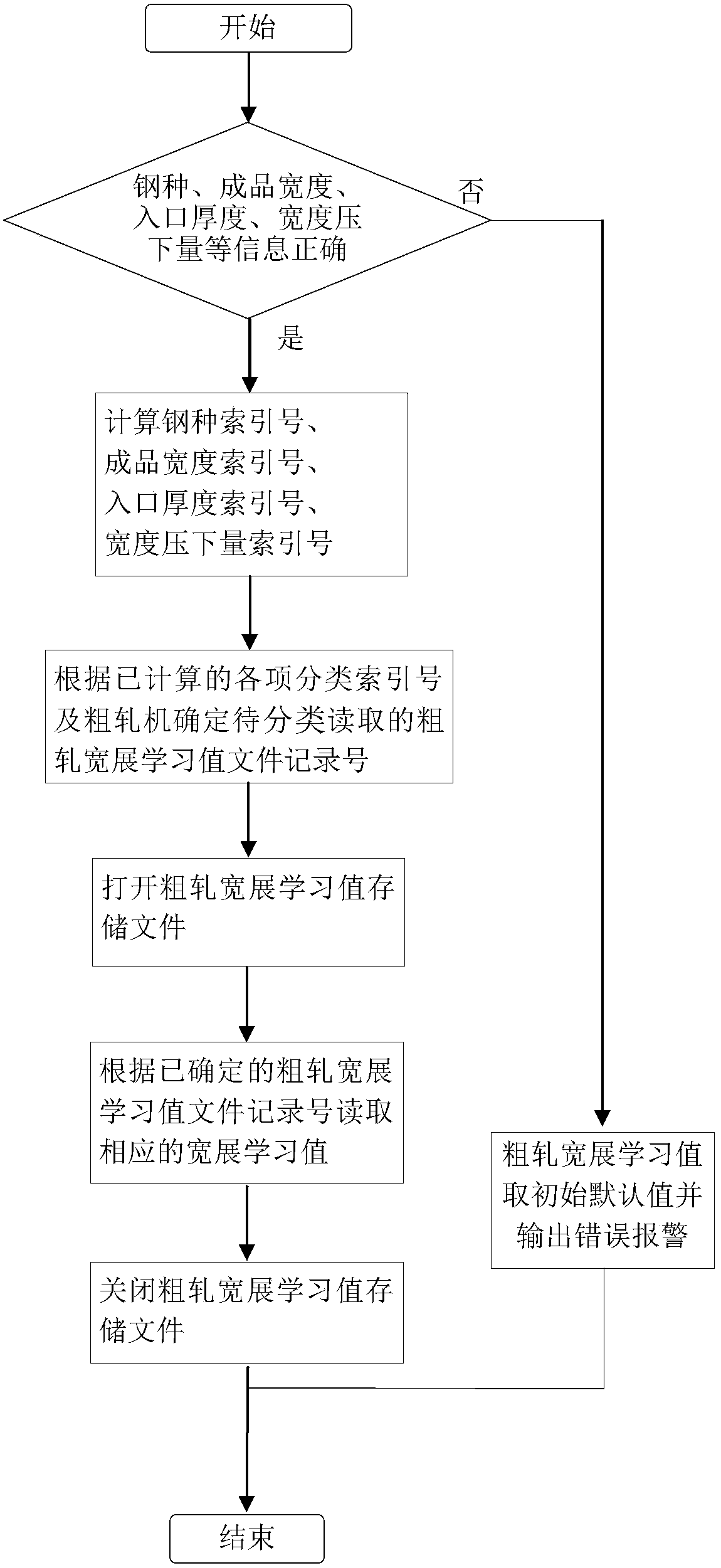

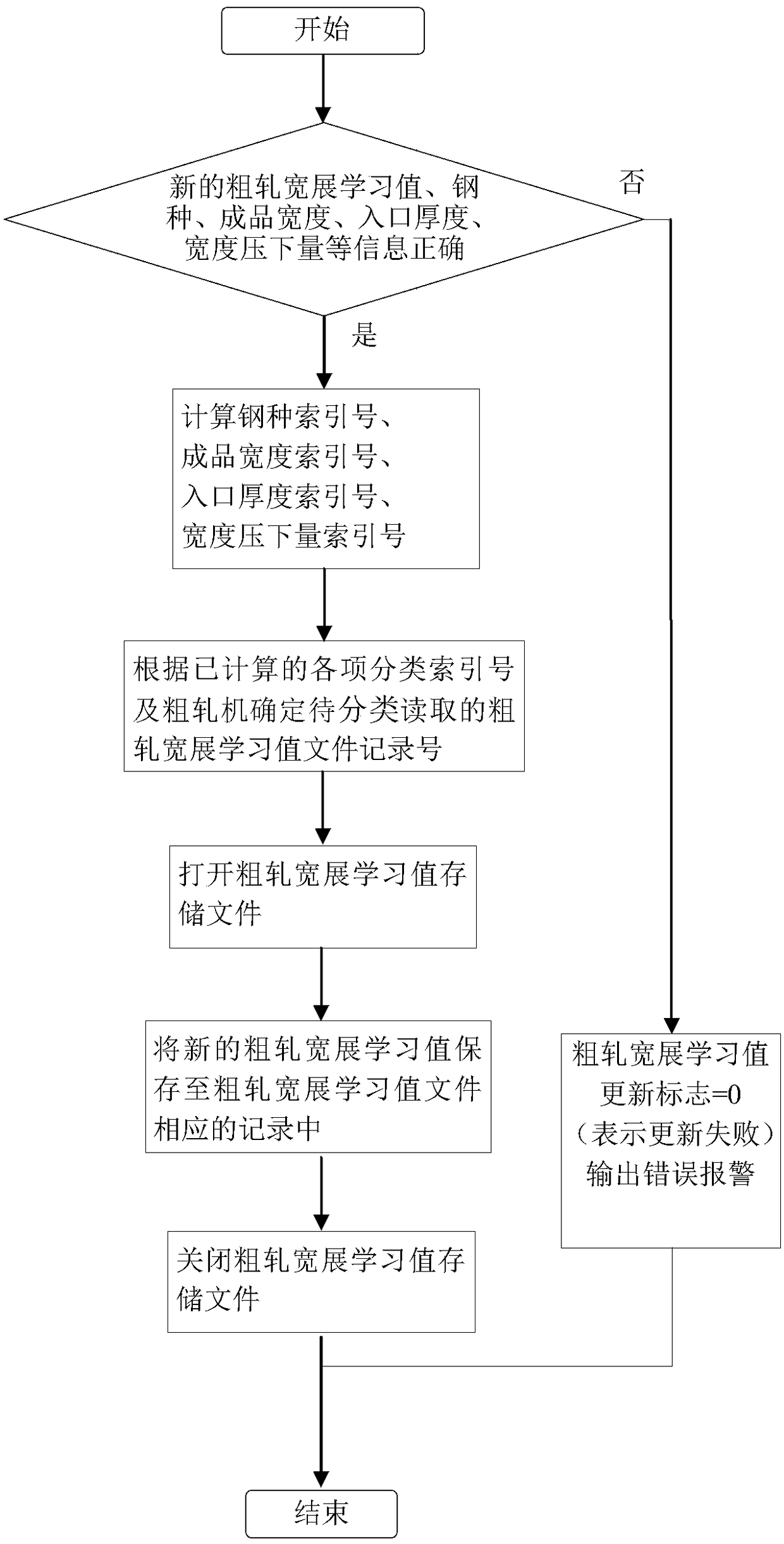

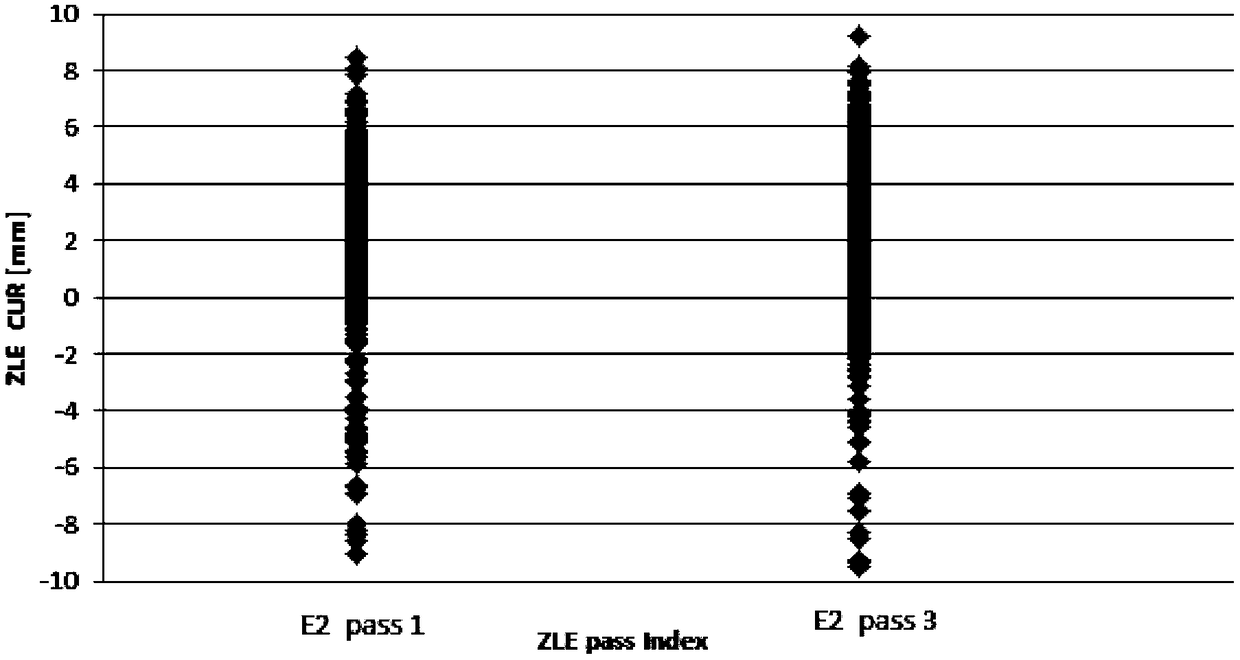

The invention discloses a computer model control method for the thickness of a hot-rolled product. The method is a method for conducting classified reading and storing on the rough rolling broadeningstudy value according to the steel ball, the product thickness, a rough rolling machine, the width rolling reduction and the inlet thickness. Compared with the prior art, the computer model control method has the beneficial effects that the rough rolling broadening study value is classified according to the steel ball, the product thickness, the rough rolling machine, the width rolling reduction and the inlet thickness, the relevance between various factors and the width variation in the classifying method is obvious and is not affected by the rough rolling pass combination manner and the product thickness, the rough rolling broadening study value fluctuation range is obviously reduced, the method is suitable for production of products with various incoming material plate slab thicknesses,the product width control precision can be effectively improved, and therefore the generated waste product cutting-off rate and cost losses are reduced.

Owner:ANGANG STEEL CO LTD

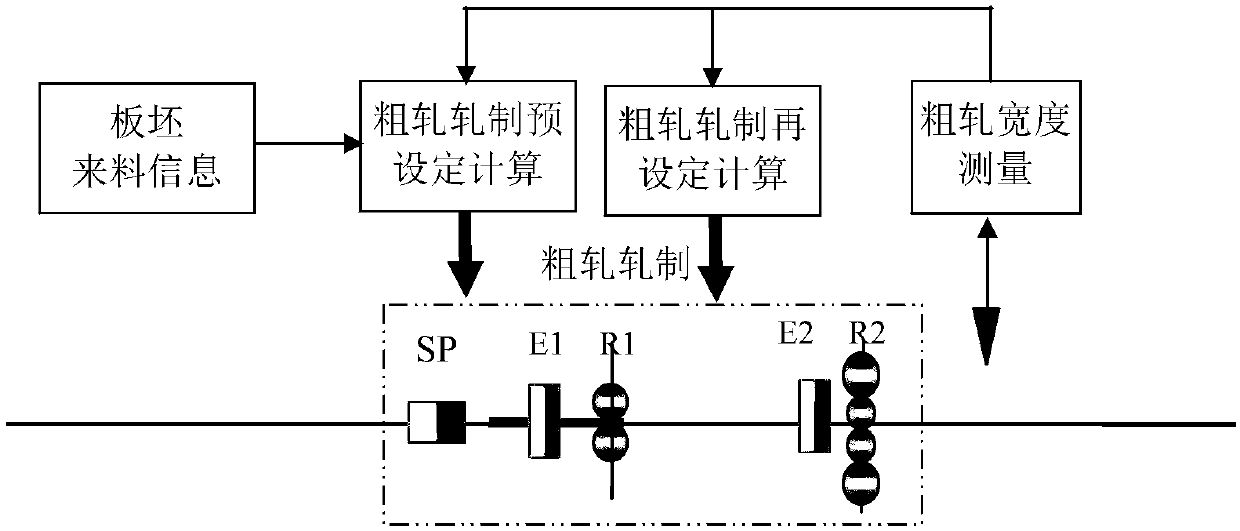

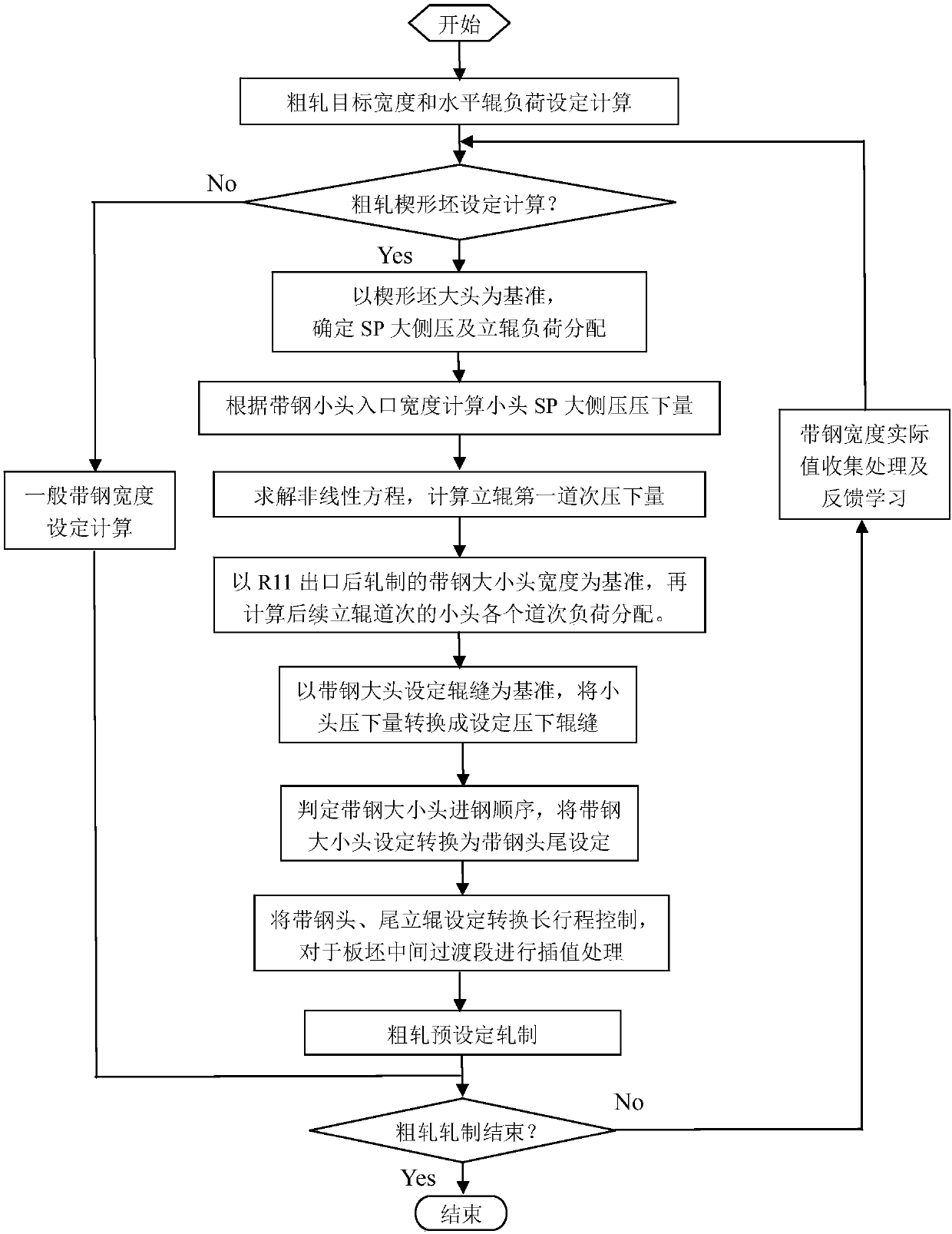

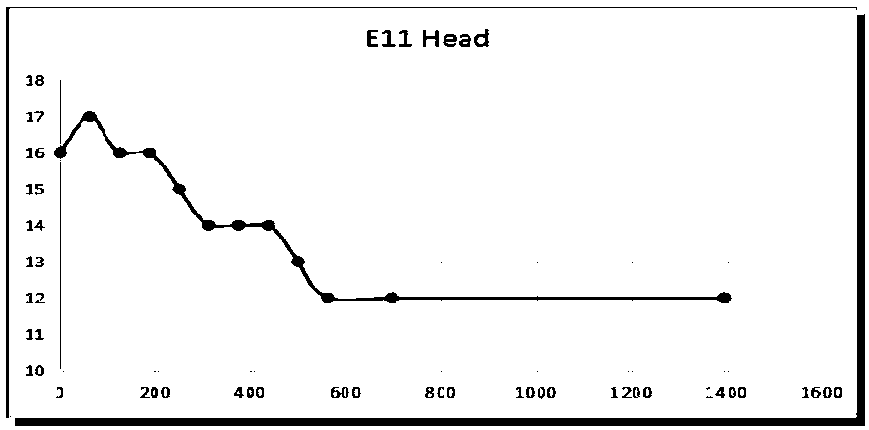

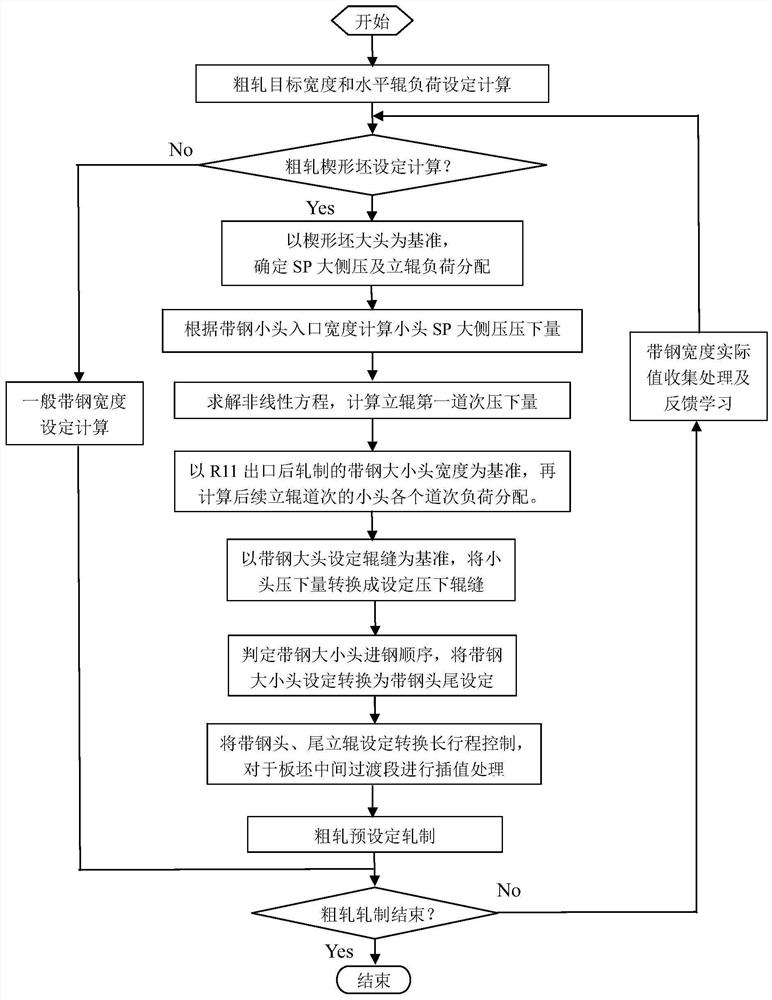

Hot-rolled wedge-shaped blank strip steel width control method

ActiveCN109772894AImproved Width Control AccuracyMetal rolling stand detailsStrip steelLoad distribution

The invention relates to a hot-rolled wedge-shaped blank strip steel width control method. The control method comprises the steps that the rough rolling objective and load distribution are completed according to the width of an incoming material of a large head at first; width reduction of all passes of a small head is determined according to the outlet width objective, determined by the large head, of all passes; and reduction is controlled through the large head and the small head of a plate blank, an on-site connection control curve is subjected to long-stroke control, and finally, rectangular control over the plate blank is achieved. According to the control method, the control precision is greatly improved, and the problem that the overall control precision of the width of a plate blank in an existing control method is not high enough is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

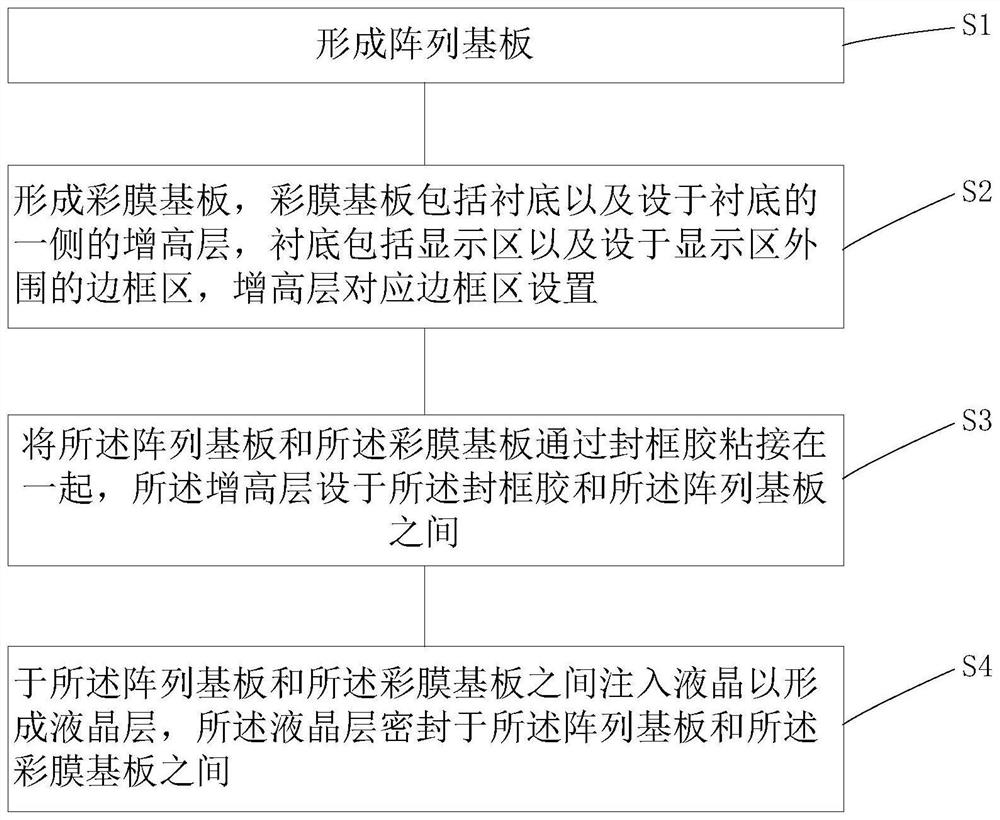

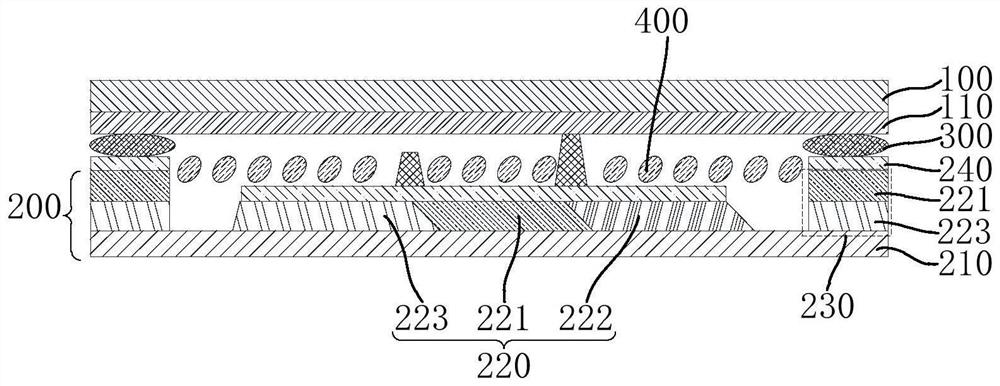

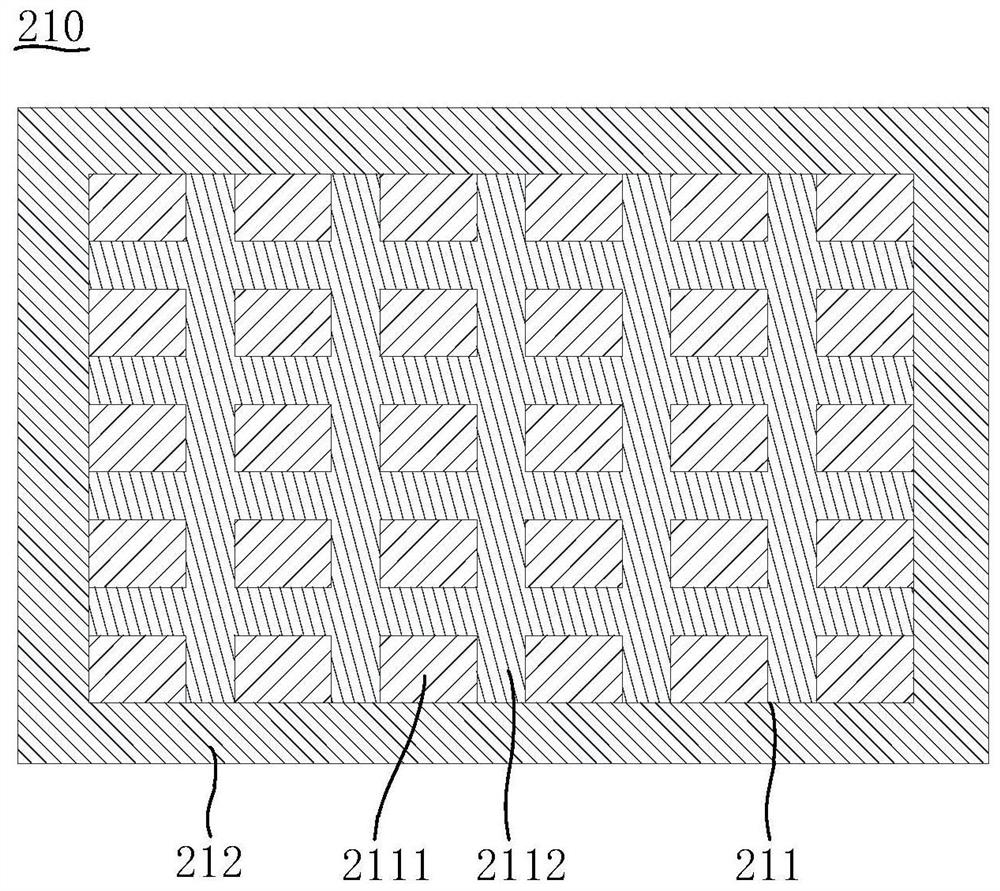

Display panel and manufacturing method thereof

InactiveCN113126356AAchieve narrow bezel designImprove overflow phenomenonNon-linear opticsColor filmEngineering

The invention is suitable for the technical field of display, and provides a display panel and a manufacturing method thereof. The manufacturing method of the display panel comprises the steps: an array substrate is formed; a color film substrate is formed, the color film substrate comprises a substrate body and a heightening layer arranged on one side of the substrate body, the substrate body comprises a display area and a frame area arranged on the periphery of the display area, the heightening layer is arranged corresponding to the frame area, and the thickness of the heightening layer ranges from 2.9 micrometers to 4.6 micrometers; the array substrate and the color film substrate are bonded together through the frame sealing glue, so that the heightening layer is arranged between the frame sealing glue and the array substrate; and a liquid crystal layer is formed between the array substrate and the color film substrate, and the liquid crystal layer is sealed between the array substrate and the color film substrate. According to the display panel, under the condition that the gap of the liquid crystal layer is kept unchanged, the thickness of the frame sealing glue is smaller, the phenomenon that the frame sealing glue overflows to the two sides is improved, the width of the frame sealing glue can be reduced, and the width control precision of the frame sealing glue can be improved.

Owner:BEIHAI HKC OPTOELECTRONICS TECH CO LTD +1

Production facility and method for high-intensity packing steel belt

InactiveCN100423857CRounded cornersHigh elongationWork treatment devicesMetal rolling arrangementsPhosphorHigh pressure water

The invention relates to a method for producing high-strength packing steel band. Wherein, the inventive device comprises material preparer, induction heating furnace, end cutter, high-pressure water dephosphorize device, eight thermal rollers, one cold roller, middle cooling section, wide closed controller, thickness closed controller, movable sleeve, coater, and coiler; and the method comprises: preparing materials, induced heating, cutting end, removing phosphor, thermally rolling, controlling width, cooling, cold rolling, coating, coiling, while it can add welder and additive heater. In the production, the temperature of heating furnace should be controlled accurately, and the cooling speed should be controlled. The inventive steel band has high quality while the width accuracy is 0-1mm, and its cost is low.

Owner:鞍山众鼎科技有限公司

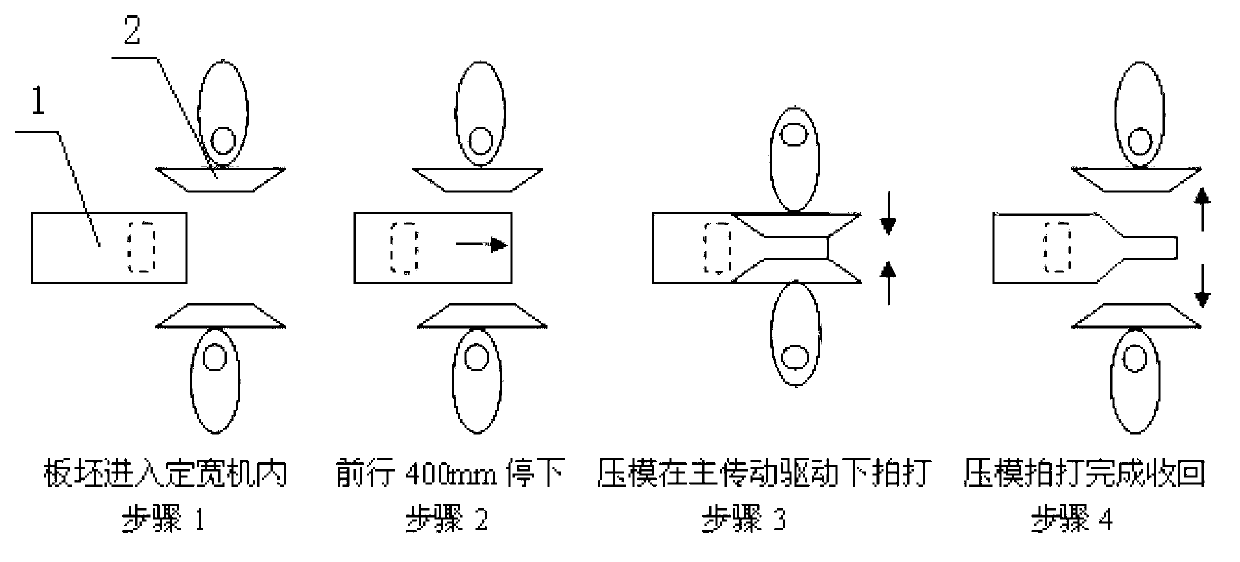

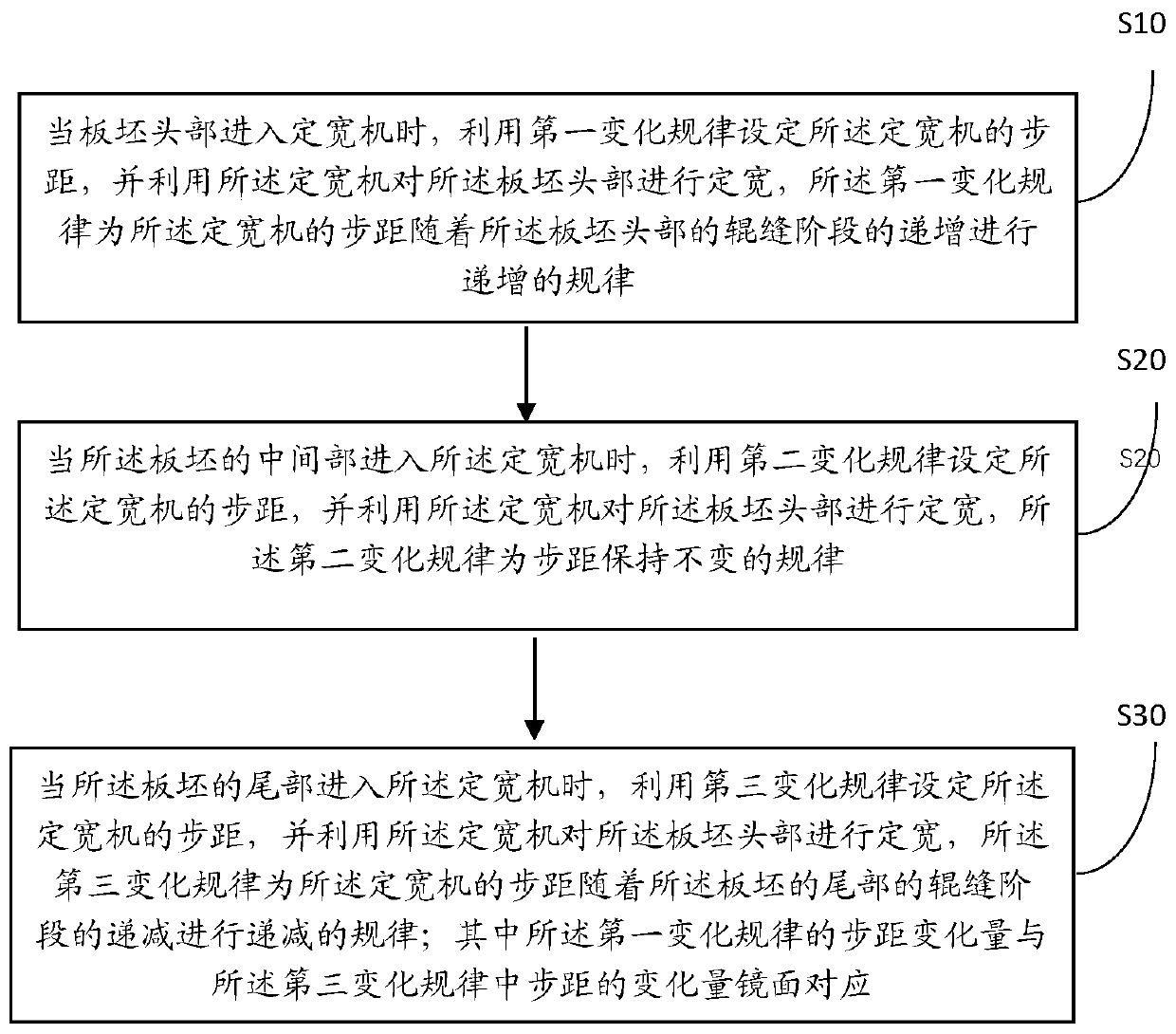

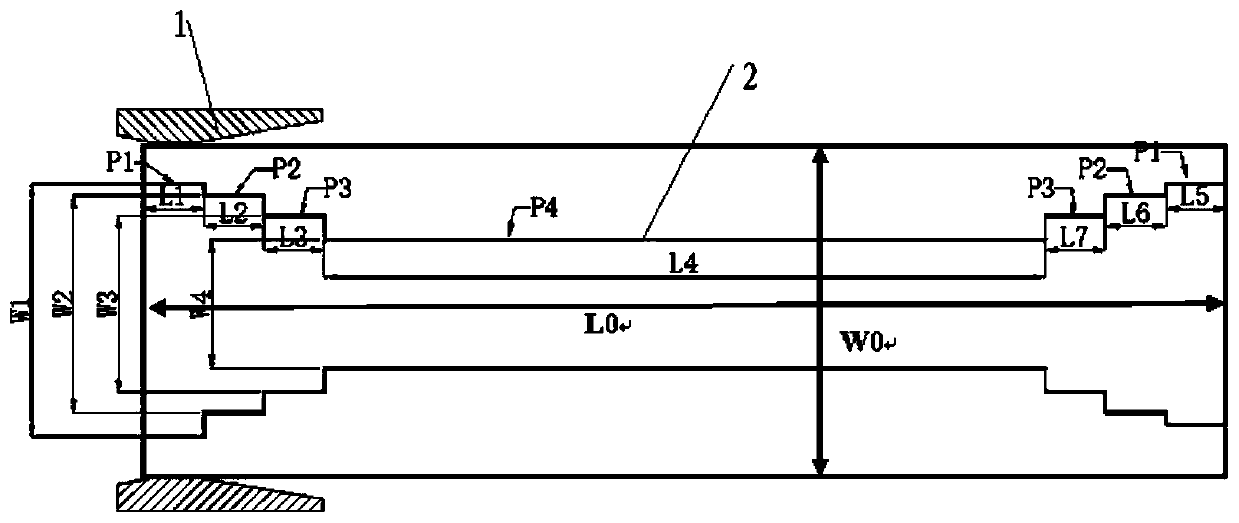

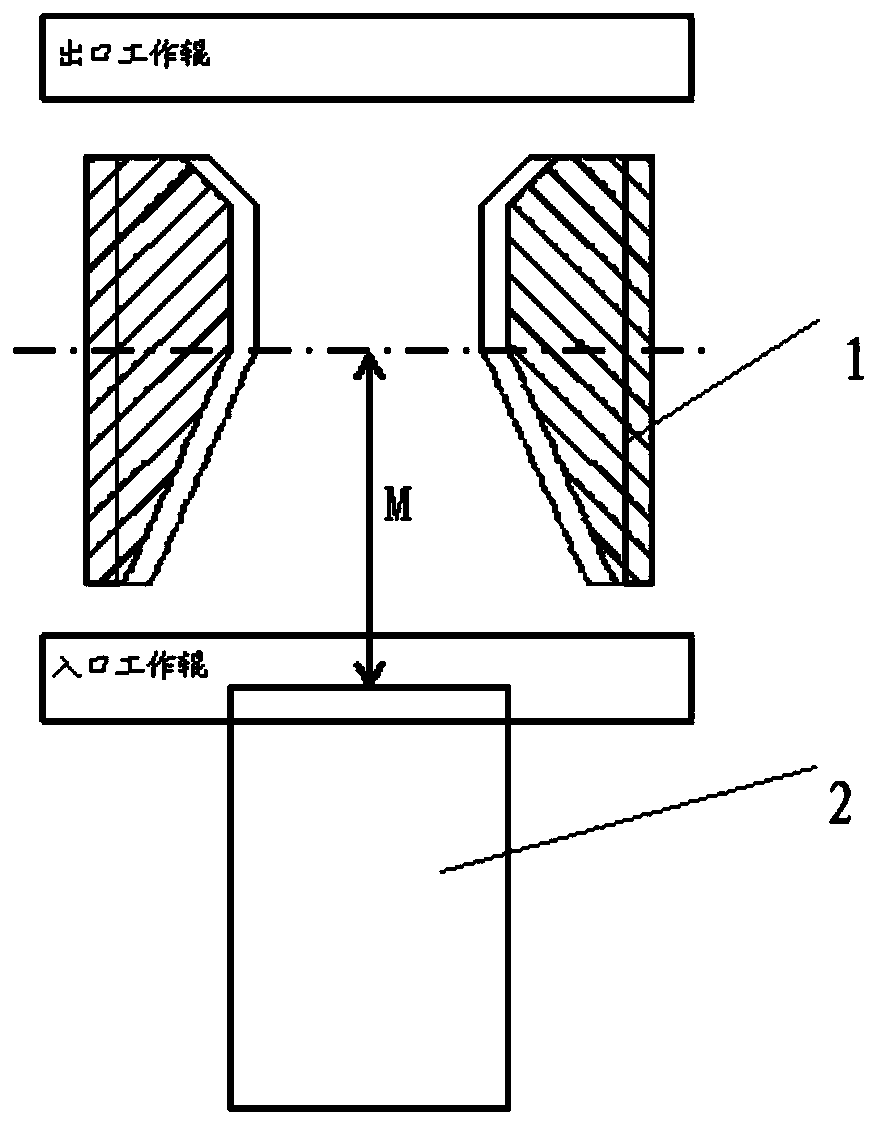

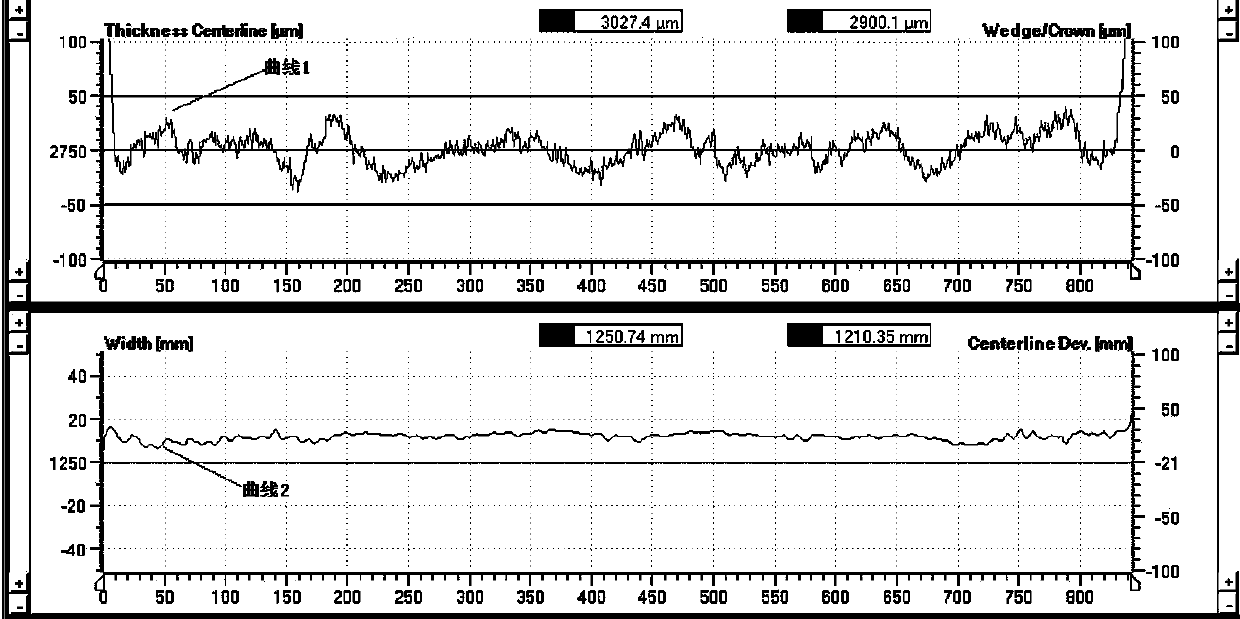

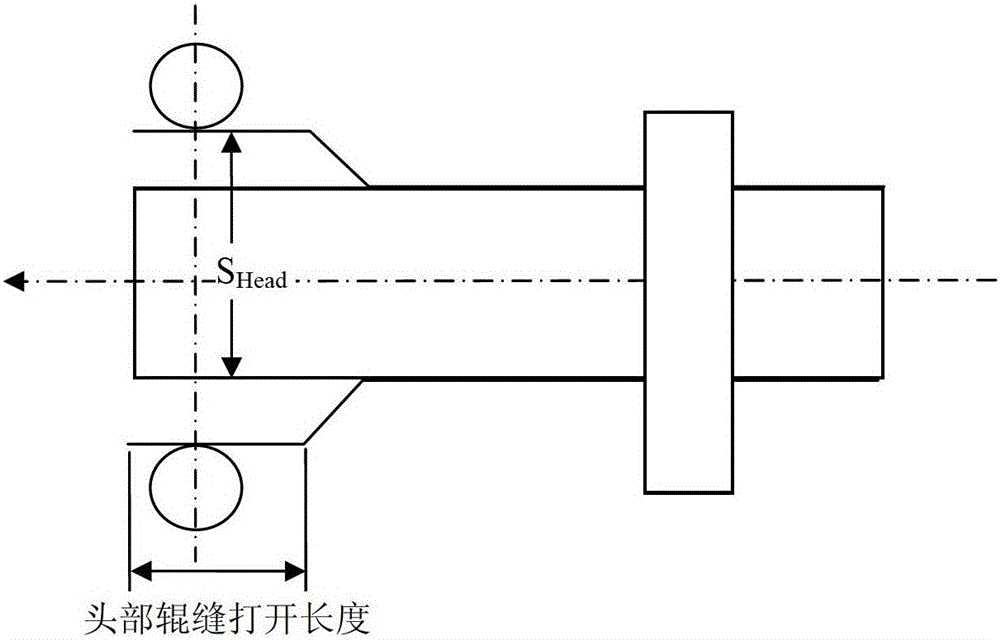

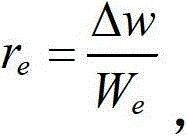

Variable step pitch head-tail width control method of fixed width machine

ActiveCN109821901AReduce the temperatureSave rolling timeMetal rolling stand detailsPulp and paper industryFirst variation

The invention provides a variable step pitch head-tail width control method of a fixed width machine. The method comprises the steps that the step pitch of the fixed width machine is set according toa first variation rule when the head of a plate blank enters the fixed width machine, and the first variation rule means that the step pitch of the fixed width machine is increased with the roll gap of the head of the plate blank in a staged mode; when the middle portion of the plate blank enters the fixed width machine, the width of the head of the plate blank is fixed through the fixed width machine, and the step pitch is constant according to a second variation rule; when the tail of the plate blank enters the fixed width machine, the step pitch of the fixed width machine is set in accordance with a third variation rule, and the third variation rule means that the step pitch is decreased in a multi-staged mode; and the variation amounts of all the stage of the first variation rule and the third variation rule are in mirror symmetry. The method achieves the technical effects that through layered control over the step pitch of the fixed width machine, the problem that the head end andthe tail end of metal of steel with high hardness level and widened amount are not restrained, and consequently width reduction is caused is effectively solved, the width control precision of the fixed width machine is effectively improved, and the product yield is increased.

Owner:BEIJING SHOUGANG CO LTD

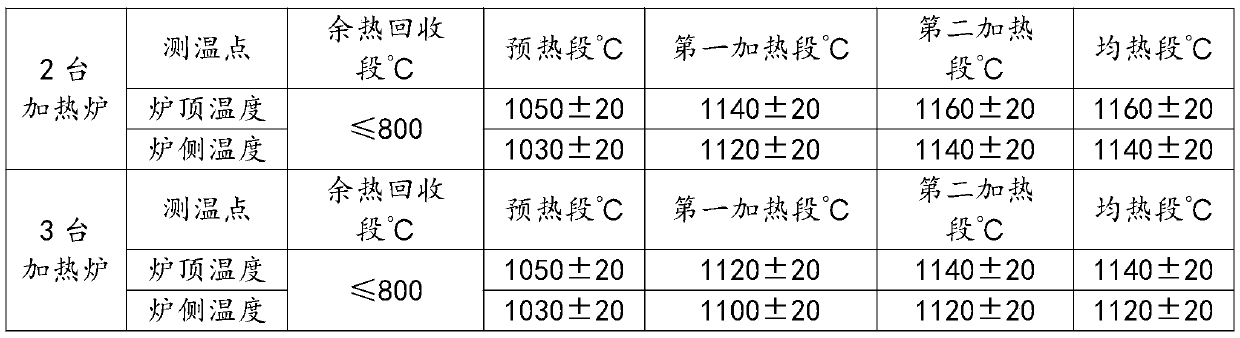

Preparation method of hot-rolled strip steel

InactiveCN110899338AImproved Width Control AccuracyIncreasing the thicknessMetal rolling stand detailsTension/compression control deviceManufacturing engineeringLoad distribution

The invention provides a preparation method of hot-rolled strip steel. The method comprises the steps of heating, rough rolling, finish rolling and winding, in the finish rolling process, under the condition of normal rolling production of seven continuous rolling machines F1-F7 of a finishing mill unit, before the strip steel enters a finishing mill, the rolling parameters of the seven continuousrolling machines F1-F7 are input in a controller, the rolling parameters comprise load distribution coefficients and movable sleeve unit tension coefficient, and then the strip steel are put into rolling production; and when the last rolling mill F7 of the finishing mill unit bite steel, and the automatic thickness control AGC gain value is cured according to the measured data of the strip steelhead fed back by a meter. According to the preparation method, through the load distribution, the AGC gain adjustment and the optimization of the movable sleeve tension operation, so that the problemof thickness and width fluctuation caused by rolling of a series of grade silicon steel is solved, the width control precision of the hot-rolled strip steel is improved, the thickness and width fluctuation in actual production control are reduced, the thickness and the width hit rate of the finished product are improved, and the occurrence of the condition of steel stacking is avoided.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +1

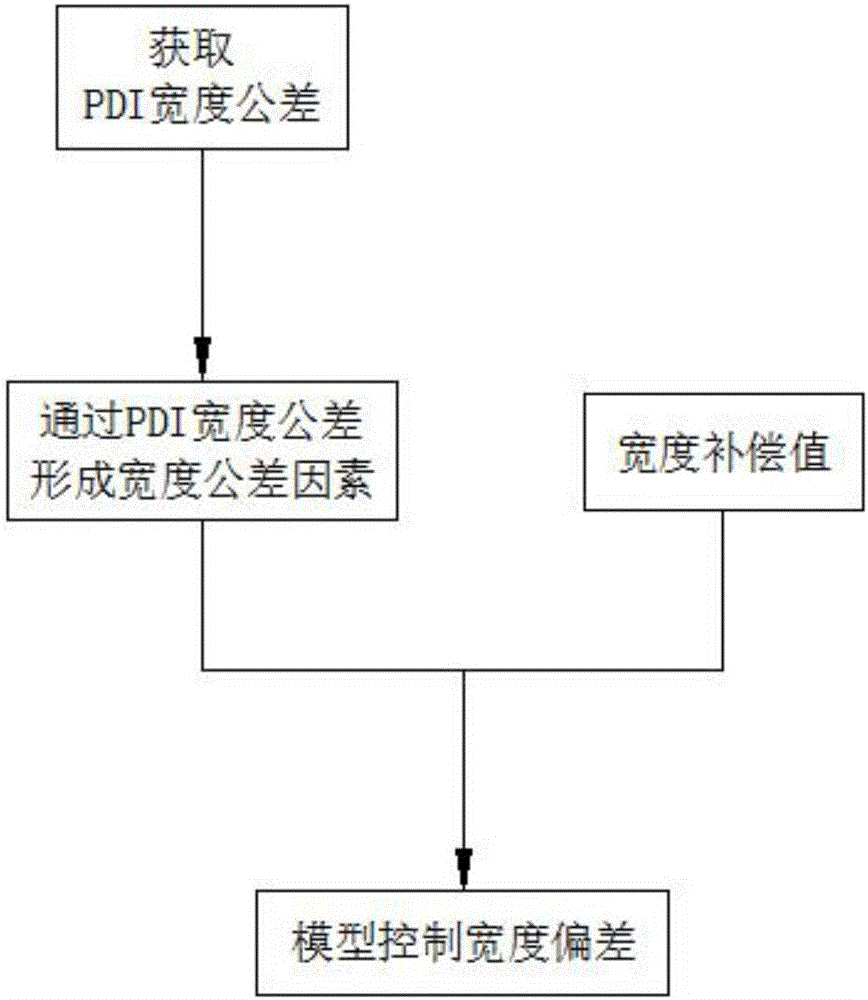

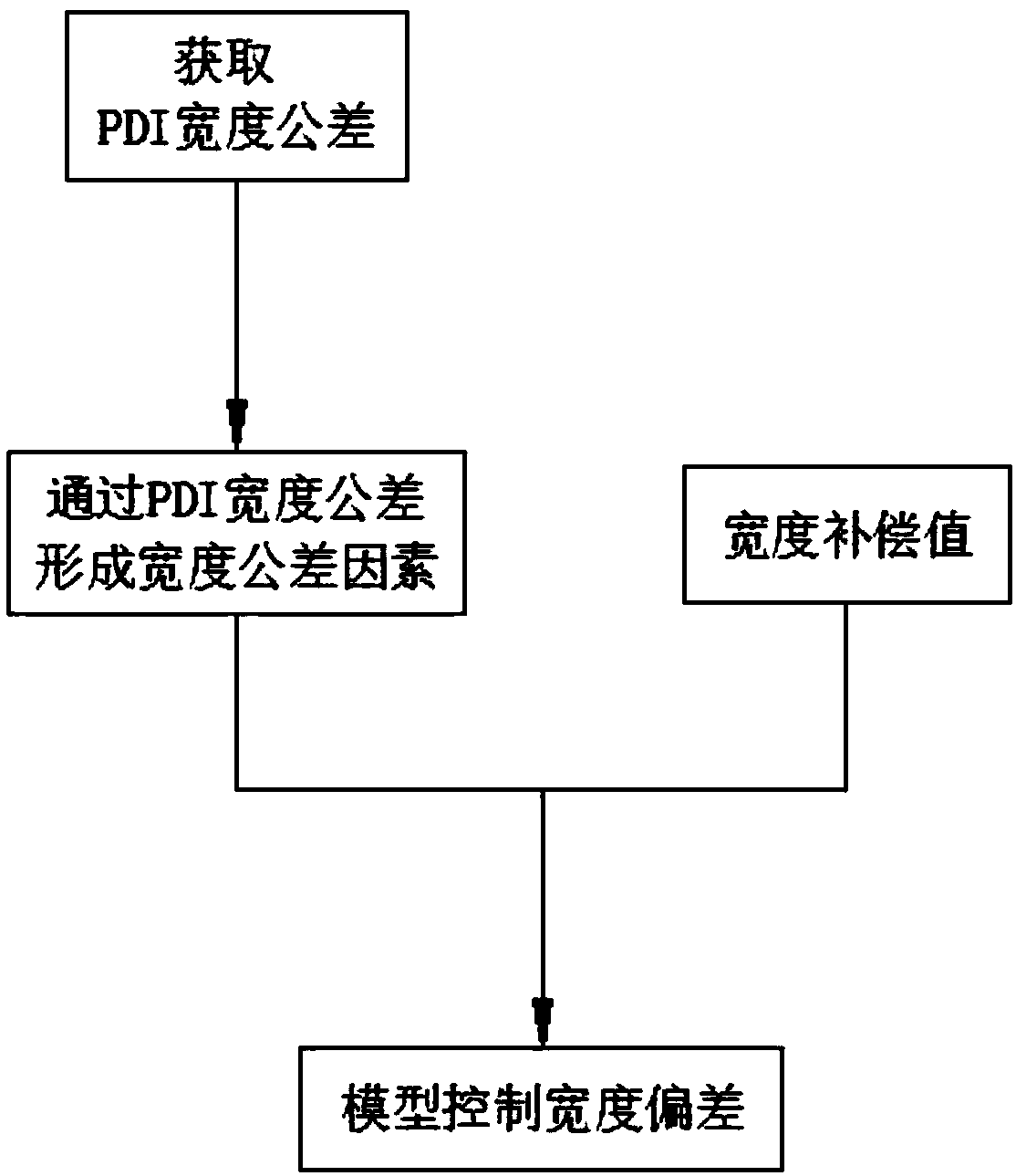

Method for improving strip steel width control precision

ActiveCN106334715AImproved Width Control AccuracyImprove pass rateMetal rolling stand detailsRoll mill control devicesModel controlStrip steel

The invention provides a method for improving the strip steel width control precision and relates to a method applicable to control of the steel strip width. In order to overcome defects in the prior art, the method for improving the strip steel width control precision is provided. The method for improving the strip steel width control precision comprises the following steps: a PDI width tolerance is acquired; a width tolerance factor is formed through the PDI width tolerance; and the width tolerance factor and a width compensation value are combined to form a model control width deviation.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

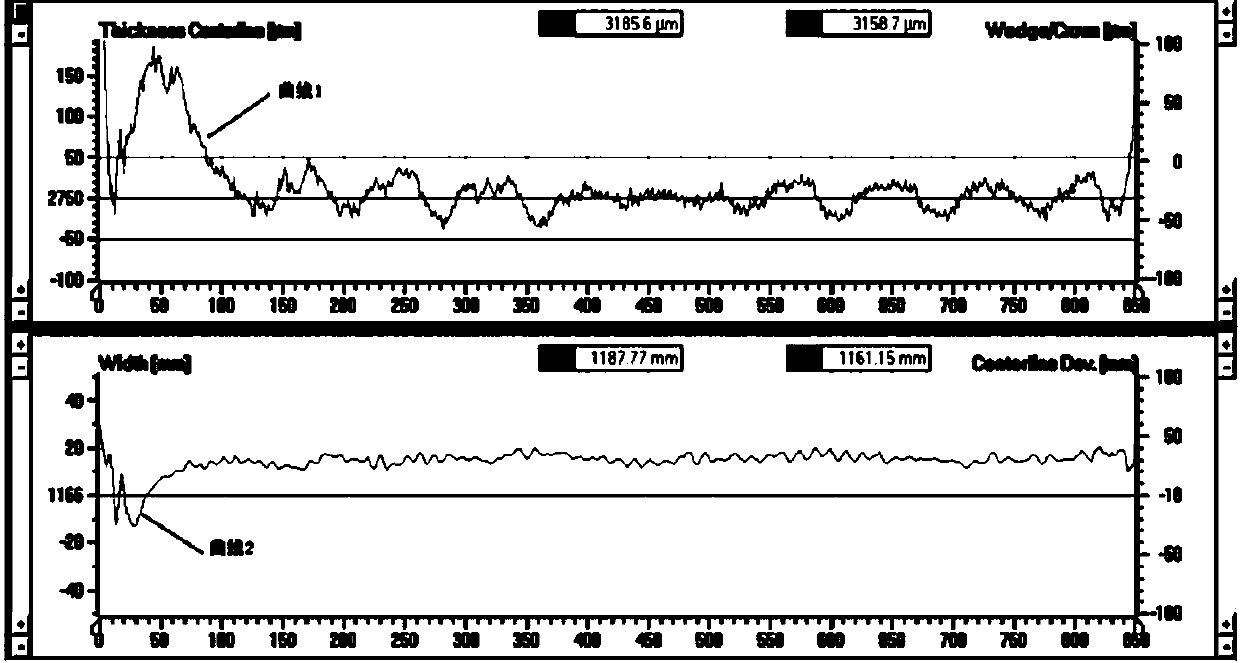

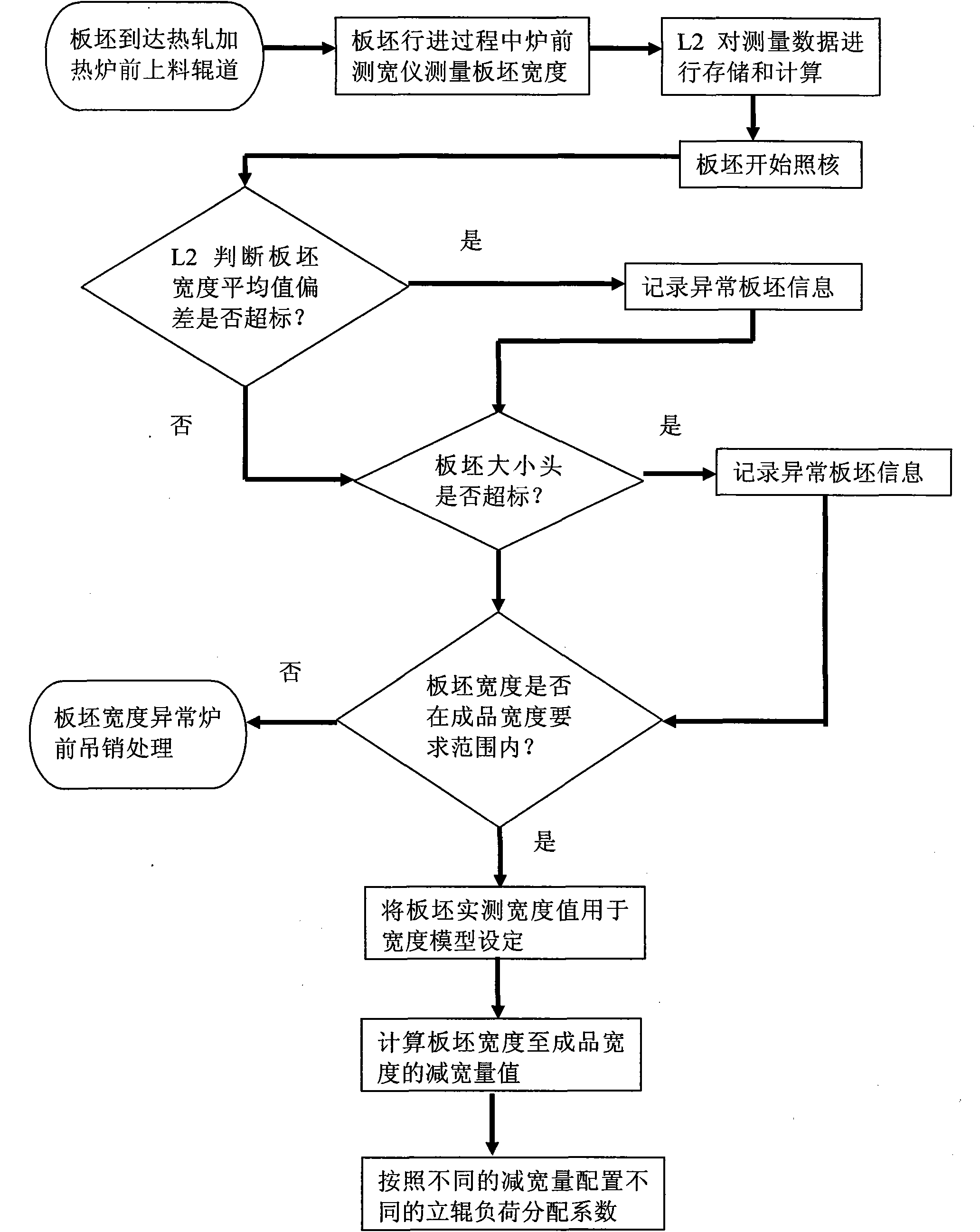

Method for controlling width of plate blank by using stokehold width gauge

InactiveCN102553940BReduce strip width problemsAvoid narrowing quality defectsRoll mill control devicesMetal rolling arrangementsEngineeringStrip steel

The invention relates to a method for controlling width of a hot roller plate blank, in particular to a method for controlling width of the plate blank by using a stokehold width gauge, and mainly solves a technical problem of quality defect such as narrowly pulled strip which is easily occurred in an aequilate rolling process and a small width reduction amount rolling process. The method comprises the following steps: measuring the width data of the plate blank by the stokehold width gauge, transferring the data to an L2 to store and compute; performing width comparison during a plate blank irradiation verification process, recording abnormal plate blank information if the error is higher than a tolerance range, performing the next plate blank big end and small end judging process no matter the plate blanks are normal or abnormal; performing the step of judging whether the width of the plate blank is ranged in the product width request no matter whether the big end value and the small end value of the plate blank are bigger than the width tolerance range; setting a width model with an actually measured width if the width of the plate blank is in the range of the product width request, and setting the width reduction amount values; configuring different vertical roller load distribution coefficient according to the different width reduction amount, and performing withdrawing treatment when the width of the plate blank is more than the range of the product width request.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

A computer model control method for the width of hot-rolled products

ActiveCN107626748BNarrowing the volatility rangeReduce cost lossMetal rolling stand detailsRoll mill control devicesWaste productClassification methods

The invention discloses a computer model control method for the thickness of a hot-rolled product. The method is a method for conducting classified reading and storing on the rough rolling broadeningstudy value according to the steel ball, the product thickness, a rough rolling machine, the width rolling reduction and the inlet thickness. Compared with the prior art, the computer model control method has the beneficial effects that the rough rolling broadening study value is classified according to the steel ball, the product thickness, the rough rolling machine, the width rolling reduction and the inlet thickness, the relevance between various factors and the width variation in the classifying method is obvious and is not affected by the rough rolling pass combination manner and the product thickness, the rough rolling broadening study value fluctuation range is obviously reduced, the method is suitable for production of products with various incoming material plate slab thicknesses,the product width control precision can be effectively improved, and therefore the generated waste product cutting-off rate and cost losses are reduced.

Owner:ANGANG STEEL CO LTD

A strip width control method for hot-rolled wedge-shaped billet

ActiveCN109772894BImproved Width Control AccuracyMetal rolling stand detailsStrip steelLoad distribution

Owner:BAOSHAN IRON & STEEL CO LTD

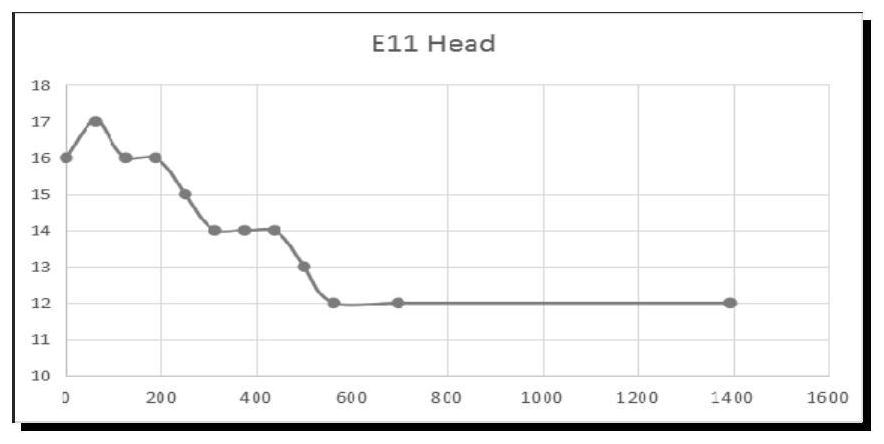

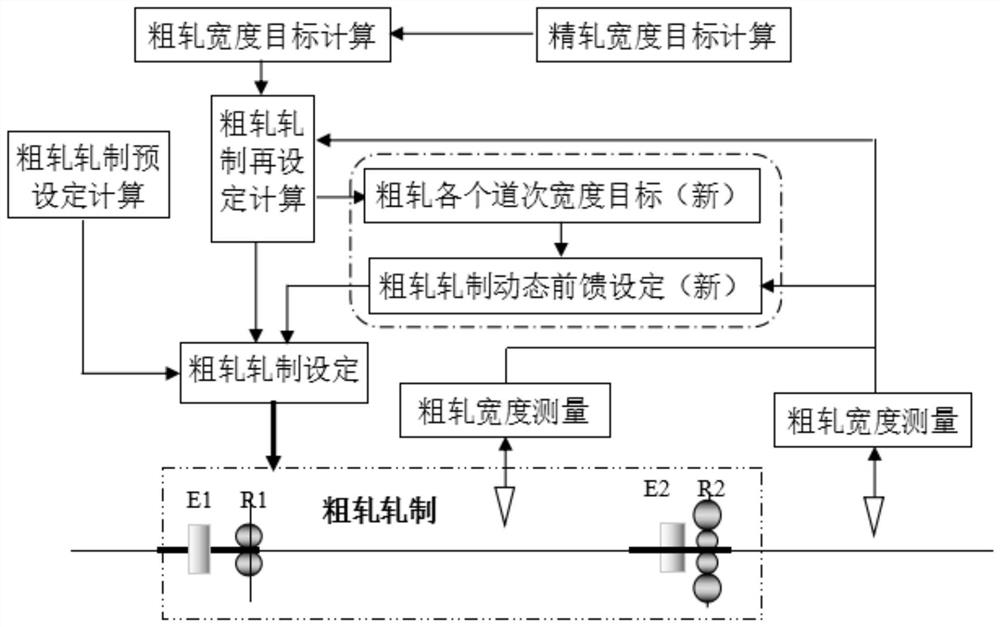

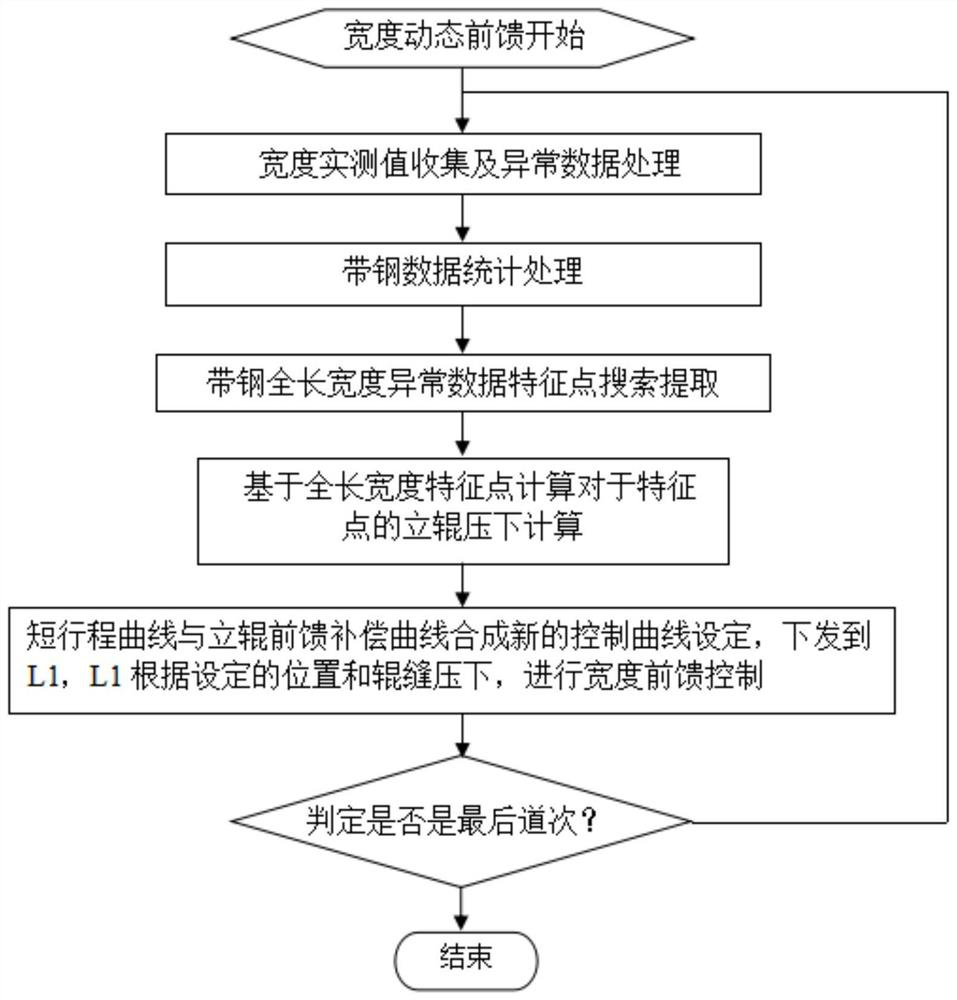

A Dynamic Feedforward Control Method for Rough Rolling Width

ActiveCN110293135BSolve the problem of unevenness in the overall length directionImproved Width Control AccuracyMetal rolling stand detailsRoll mill control devicesControl engineeringStrip steel

Owner:BAOSHAN IRON & STEEL CO LTD

Method for controlling width of hot rolling strip steel

ActiveCN103170508BSolve the shortcomings of poor interference adaptabilityReduce the situation where the amount of control is too largeMetal rolling stand detailsClosed loop feedbackData acquisition

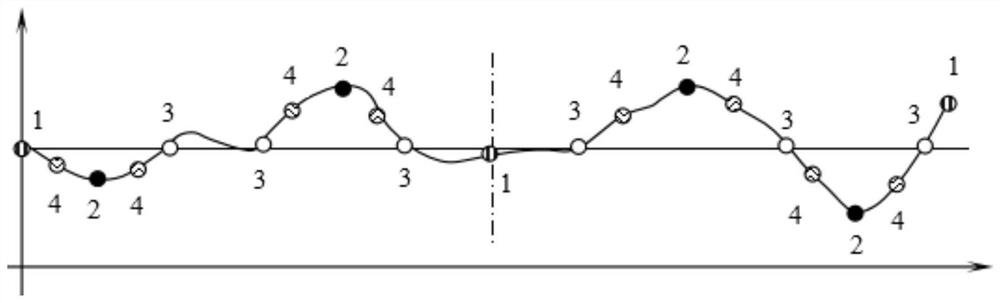

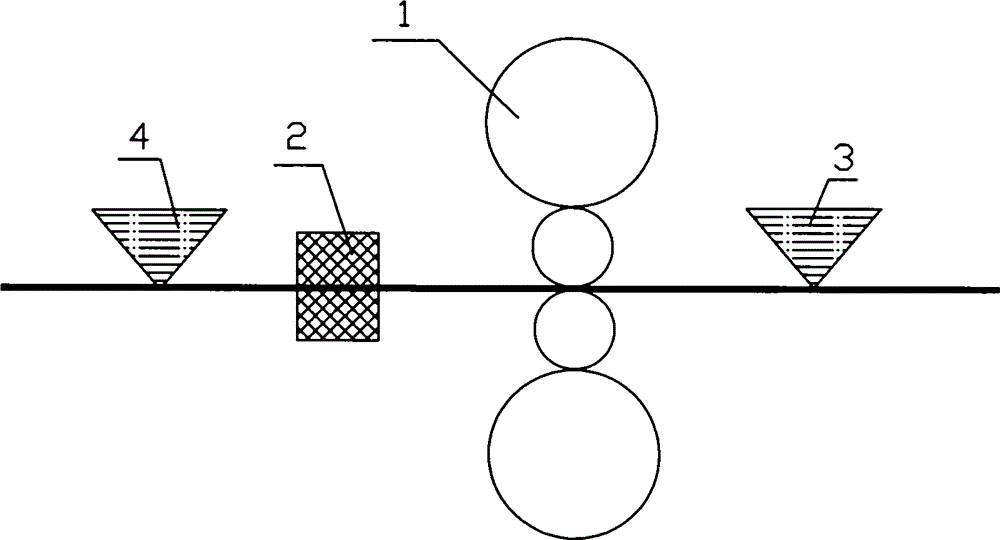

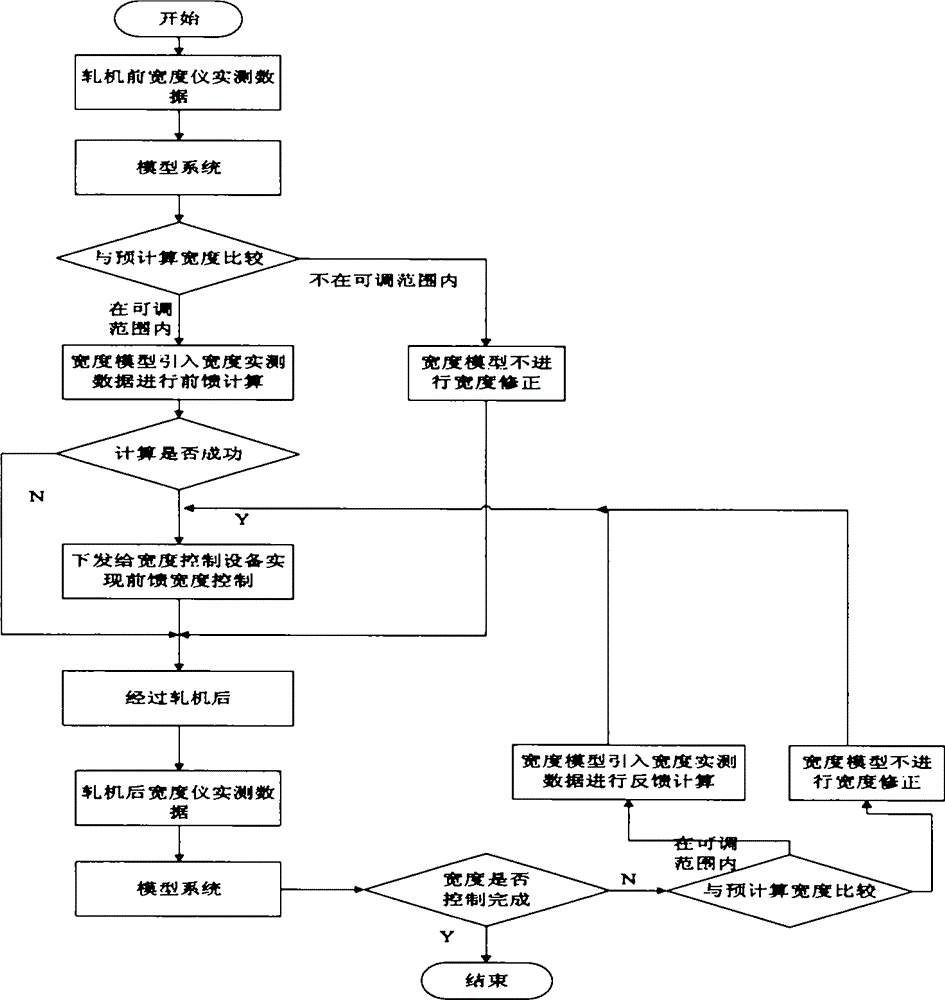

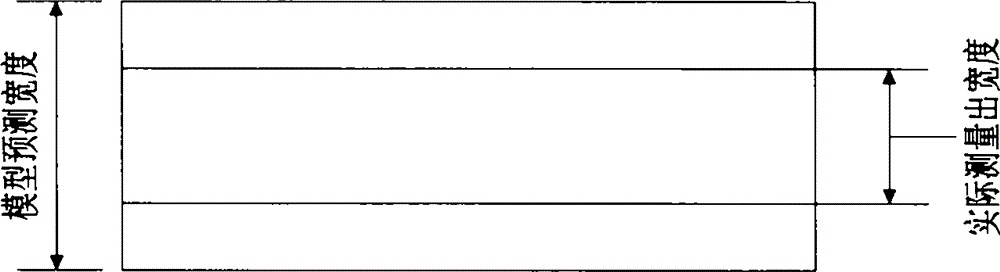

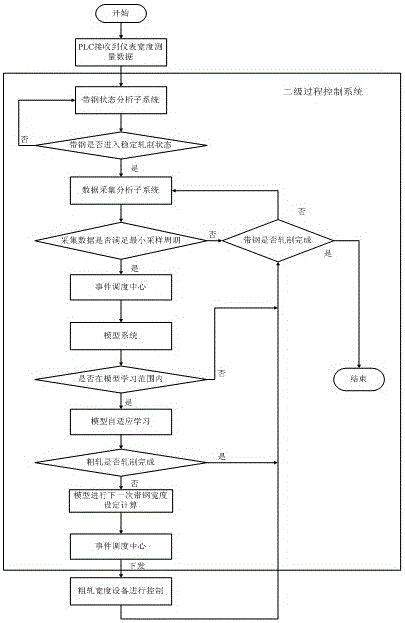

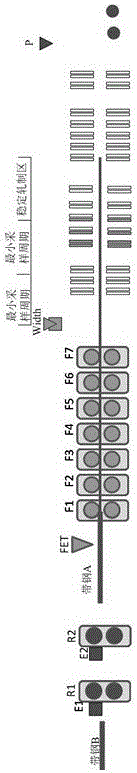

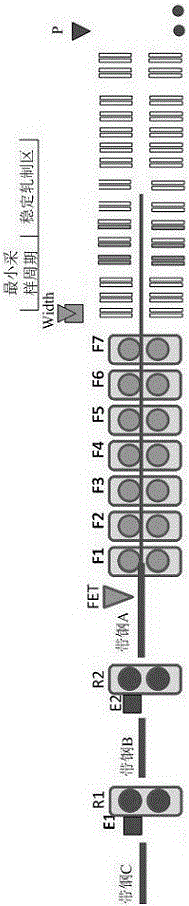

The invention belongs to the technical field of hot rolling production and control, and provides a method for controlling the width of hot rolling strip steel. Width-measuring devices are additionally arranged at the front and the back of a vertical rolling mill of width-controlling equipment, width data of strip billets at the front and the back of a horizontal mill are collected in real time, the real-time width data are transmitted to a data acquisition system before the strip billets enter the mill, and the data acquisition system transmits the width data to a model system; the model system compares the width data acquired in real time with predicted data predicted by a model, and then determines whether width control is corrected or not, if width disturbance is large, width open loop feedforward control is carried out at first, after the belt billets leave the width-controlling equipment and the horizontal mill, mill rear width detection equipment sends corresponding data to the model system, the model system carries out calculation again, on-line control of a vertical roll is achieved through basic automation, and therefore closed loop feedback control is formed. Width detection is carried out on a plate billet at first before the plate billet enters the width-controlling equipment, dynamic correction is carried out on basic automation system control equipment, and therefore the width disturbance is reduced, and width feedforward and feedback dynamic control is realized.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

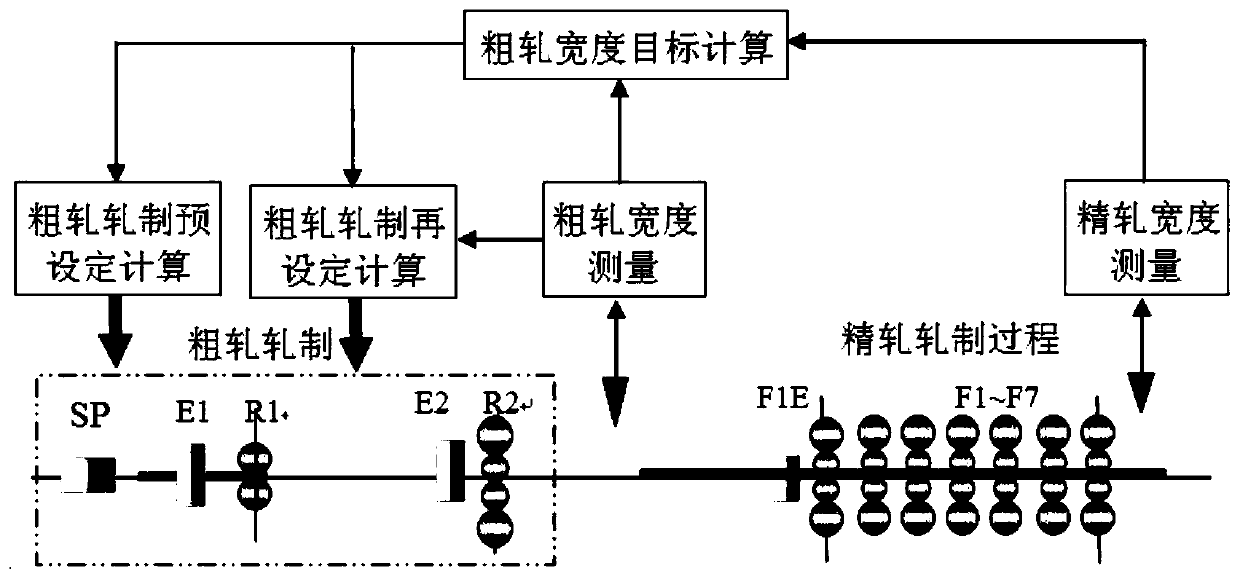

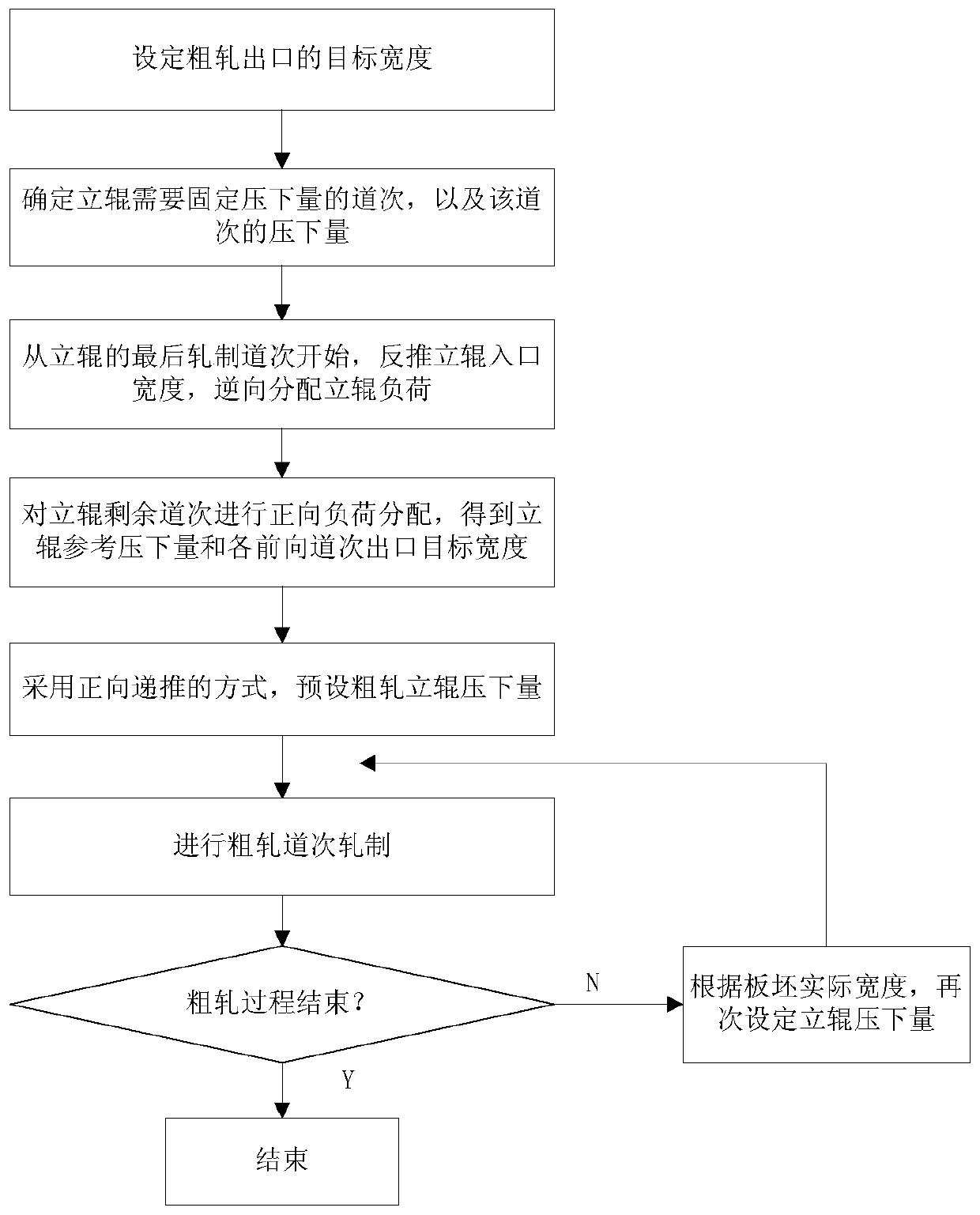

A method for controlling rough rolling width of slab

ActiveCN108941208BImprove controlEfficient use ofMetal rolling stand detailsRoll mill control devicesControl objectiveControl engineering

The invention relates to a rough rolling width control method of a plate blank. According to the rough rolling width control target, firstly, the pass of rolling reduction needing to be fixed by a vertical roll and the rolling reduction of the pass are determined according to needs; then, starting from the last rolling pass of the vertical roll, the inlet width of the vertical roll is reversely pulled to be used as the target width of the previous pass or several passes according to the rolling reduction, and vertical roll loads of one or more passes is distributed reversely; finally, the restof passes of the vertical roll is subjected to forward load distribution; and after the plate blank completes rolling of every pass, rolling recalculation is started, and the rolling reduction of thevertical roll is re-set according to newest production information. According to the method, the measured value generated after rolling of the plate blank can be utilized more effectively, manual intervention of operation workers can be greatly reduced, the width control precision can be obviously improved, and the problem that the width control precision of a plate blank is low due to manual intervention in an existing rough rolling width control method is solved.

Owner:BAOSHAN IRON & STEEL CO LTD

A method for automatic control of strip width in cold rolling process

ActiveCN104942019BEliminate Width FluctuationsEliminate the effects ofMetal rolling stand detailsRoll mill control devicesAutomatic controlStrip steel

The invention relates to an automatic control method for width of steel strips during cold rolling, and belongs to the technical field of automatic control. The method includes: establishing forecasting models for width of exit steel strips for each stand; detecting width measured value at each position in the longitudinal direction of hot-rolled steel strips from an entry of a cold rolling unit in real time; calculating the differences between the measured values and preset values of width of the hot-rolled steel strips, and obtaining width variation of the hot-rolled steel strips to be eliminated by each stand; performing length position tracking on the hot-rolled steel strips from the entry of the cold rolling unit to obtain predicted values of exit width variation of the unit; determining real-time compensation of plate-shaped regulating mechanism of the No. m stand by changing compensation value of the plate-shaped regulating mechanism of a rolling mill of the stand in real time; according to the real time compensation of the plate-shaped regulating mechanism of each stand, performing feedforward control for exit width of each stand, and timely eliminating fluctuation of the width of the hot-rolled steel strips and influence on width of exit steel strips at the last stand by rolling technology parameter variation of each stand to improve width control precision of cold-rolled steel strips and stability of cold-rolling production process.

Owner:BAOSHAN IRON & STEEL CO LTD

Device for tracing and detecting interior plate blank head position of fixed width machine

InactiveCN103341499BIncreased rolling timeDecreased width control accuracyRoll mill control devicesMetal rolling arrangementsPower flowMachine control

Owner:武汉钢铁有限公司

Energy-saving type sectional rack water collecting tube device and control method thereof

InactiveCN111283000ASolve the problem of temperature unevenness in the width directionImprove mechanical stamping performanceProfile control deviceMetal rolling arrangementsSpray nozzleStructural engineering

The invention discloses an energy-saving type sectional rack water collecting tube device and a control method thereof. The energy-saving type sectional rack water collecting tube device comprises a rack water collecting tube and further comprises a central controller and a base automatic assembly, wherein the rack water collecting tube comprises an upper rack water collecting tube, an upper rackwater inlet tube connected onto the upper rack water collecting tube, an upper water inlet tube blocker for fixing the upper rack water inlet tube as well as a lower rack water collecting tube, a lower rack water inlet tube and a lower water inlet tube blocker which are in mirror symmetry with the upper rack water collecting tube, the upper rack water inlet tube and the upper water inlet tube blocker separately, wherein a plurality of spray nozzles are arranged on the upper rack water collecting tube; the central controller is used for issuing a strip steel width layer instruction; and the base automatic assembly is used for receiving the instruction issued by the central controller to realize controlling the rack water collecting tube to spray cooling water to a strip steel surface in a sectional mode. The energy-saving type sectional rack water collecting tube device improves strip steel width dimension precision, solves the hot-rolled strip steel edge performance defect, further reduces energy consumption, realizes reducing cost and improving efficiency, and improves product competitiveness.

Owner:BAOSHAN IRON & STEEL CO LTD

The Method of Improving the Controlling Accuracy of Strip Width

ActiveCN106334715BImproved Width Control AccuracyImprove pass rateMetal rolling stand detailsRoll mill control devicesModel controlStrip steel

The invention provides a method for improving the strip steel width control precision and relates to a method applicable to control of the steel strip width. In order to overcome defects in the prior art, the method for improving the strip steel width control precision is provided. The method for improving the strip steel width control precision comprises the following steps: a PDI width tolerance is acquired; a width tolerance factor is formed through the PDI width tolerance; and the width tolerance factor and a width compensation value are combined to form a model control width deviation.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A control method for preventing strip breakage in thin strip steel cold rolling process

ActiveCN104923568BReduce the incidence of broken beltsReduce tensile stressRoll mill control devicesMeasuring devicesReduction rateControl system

Owner:BAOSHAN IRON & STEEL CO LTD

A Method of Controlling the Slab Width Using the Gap Measurement of Vertical Rollers in Reverse Pass of Rough Rolling

ActiveCN104209339BExact width dataImproved Width Control AccuracyMetal rolling stand detailsPresent methodEngineering

In view of the fact that conventional rough-rolling vertical rollers adopt the method of empty pass during reverse rolling without carrying out width control on the strip steel, the method of the present invention is to adopt the small rolling force control mode for the vertical rollers during the rough-rolling reverse rolling. The vertical roll is rolled and the roll gap is measured, and the slab width is calculated according to the roll gap model. Use this width to re-set the rough rolling width and learn the widening model. The method can solve the problem that accurate width measurement data cannot be obtained in the middle pass of rough rolling at present, and accurately provide the slab entrance width re-set and calculated during the rough rolling process, thereby improving the final rough rolling width accuracy.

Owner:BAOSHAN IRON & STEEL CO LTD

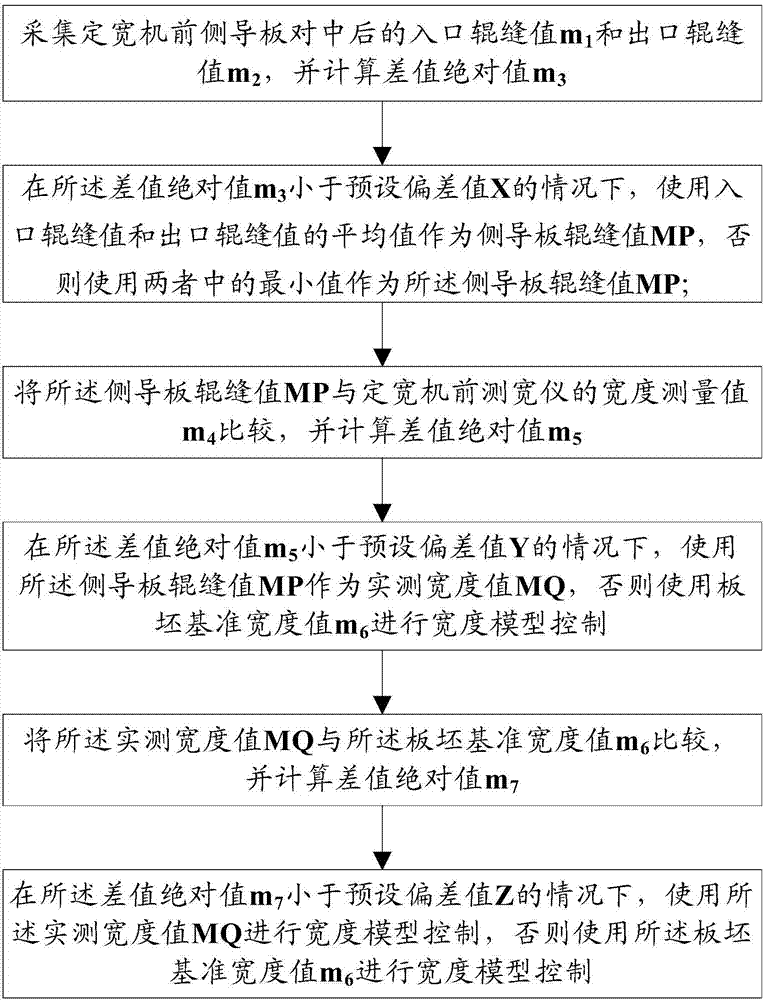

A Method of Width Model Control Using Roll Gap Value of Side Guide Plate

ActiveCN105642676BImproved Width Control AccuracyMetal rolling stand detailsRoll mill control devicesModel controlEngineering

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

A Fast Dynamic Adaptive Method for Hot Rolling Width Model

ActiveCN104707869BChange learning strategiesOptimize collection methodMetal rolling stand detailsRoll mill control devicesAdaptive learningDynamic learning

The invention relates to a hot rolling width model fast dynamic self-adapting method. According to the main control principle of the hot rolling width model fast dynamic self-adapting method, the model leaning strategy is changed, the data collecting method is improved, one time of model self-adapting leaning is conducted through width detecting equipment needed the overall pass through of a strip steel formerly, and the methods that leaning is conducted when part of the strip steel passes through the width detecting equipment, and repeatedly dynamic learning strategy is possessed are replaced. The hot rolling width model fast dynamic self-adapting method have the advantages that the problems that the width self-adapting correction is lagged in real production control, the phenomenon of width over-control occurs, and the width control deviation occurs in high-speed rolling pacing are solved, and the subsequent strip steel control precision is improved.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Rolling pressure setting method for vertical roll rolling in rough rolling area of hot continuous rolling

ActiveCN103586289BImprove rolling pressure setting accuracyImproved Width Control AccuracyTension/compression control deviceStrip steelStressed state

The invention discloses a method for setting rolling pressure of a hot continuous rough rolling area during rolling by the aid of vertical rolls. The method includes steps of firstly, computing an effective deformation degree and an effective deformation rate during rolling by the aid of the vertical rolls according to width rolling reduction of a hot-rolled plate blank on a vertical roll framework in the rough rolling area; secondly, computing deformation resistance of a rolled piece in a deformation area according to the effective deformation degree and the effective deformation rate which are obtained in the first step; thirdly, computing stress state coefficients of the rolled piece in the deformation area according to the width of a plate blank inlet, the width of an outlet and an arc length of a contact area; fourthly, computing the rolling pressure during rolling by the aid of the vertical rolls according to the deformation resistance obtained in the second step and the stress state coefficients obtained in the third step. The method for setting the rolling pressure of the hot continuous rough rolling area during rolling by the aid of the vertical rolls has the advantages that the rolling pressure setting precision of the rough rolling area during rolling by the aid of the vertical rolls can be improved, and accordingly the strip steel width control precision can be enhanced.

Owner:BAOSHAN IRON & STEEL CO LTD

A head and tail width control method for variable step distance of a fixed width machine

ActiveCN109821901BReduce the temperatureSave rolling timeMetal rolling stand detailsMachineControl theory

The present invention provides a head and tail width control method for variable step pitch of a fixed-width machine, comprising: when the head of a slab enters the fixed-width machine, the step distance of the fixed-width machine is set by using a first change law, and the first A change rule is that the step distance of the sizing machine increases with the roll gap stage of the slab head; when the middle part of the slab enters the sizing machine, the sizing machine is used to The width of the head of the slab is fixed, and the second change law is that the step distance remains unchanged; when the tail of the slab enters the width-fixing machine, the step distance of the width-fixing machine follows the third change law It is set that the third change rule is that the step distance is decreased in multiple stages; the change amount of each stage in the first and third change rules corresponds to the mirror surface. Through the layered control of the step distance of the fixed width machine, the problem of high hardness level, large amount of width reduction steel, and no metal binding at the head and tail ends leading to width loss is solved, which effectively improves the width control accuracy of the fixed width machine and improves the product quality. rate of technical effects.

Owner:BEIJING SHOUGANG CO LTD

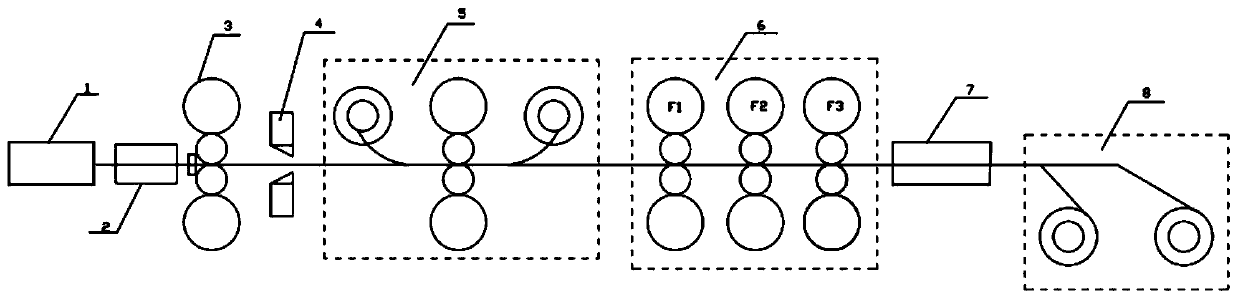

Furnace rolling mill production line

PendingCN110216144AQuality improvementImprove product competitivenessMetal rolling stand detailsRoll mill control devicesThree levelAutomatic control

The invention discloses a furnace rolling mill production line. The furnace rolling mill production line is composed of a heating furnace, a slab descaling box, a rough rolling mill, a drum type flying shear, a furnace rolling mill, a continuous rolling mill, a laminar flow cooling device and a coiling machine which are sequentially arranged. The continuous rolling mill comprises a rolling mill body F1, a rolling mill body F2 and a rolling mill body F3. The production line adopts a full hydraulic automatic width control system and a head and tail short stroke control system to control the width and head and tail shape of a rough-rolled intermediate slab. The whole production line adopts a three-level computer for control and management, the first level is a basic automation system, the second level is a process automation system, and the third level is a production quality management system. By the adoption of the furnace rolling mill production line, the whole line material tracking and automatic rolling steel control are realized, and product quality and product competitiveness are improved; width control and head and tail shape control are carried out on the rough-rolled intermediate slab so that the width control precision can be improved; the intermediate strip billet thickness precision control is realized, and the deviation is smaller; and the furnace rolling mill production line can adapt to the production of high-strength varieties and the development of new products.

Owner:SHANDONG TAISHAN STEEL GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com