Energy-saving type sectional rack water collecting tube device and control method thereof

A control method and segmented technology, applied in rolling mill control devices, contour control, metal rolling, etc., can solve the problem of uneven cooling between the middle and the sides, greater impact on energy consumption and cost, and out-of-tolerance control of strip width, etc. problems, to achieve the effect of solving uneven temperature, reducing manufacturing costs, and reducing local cold spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

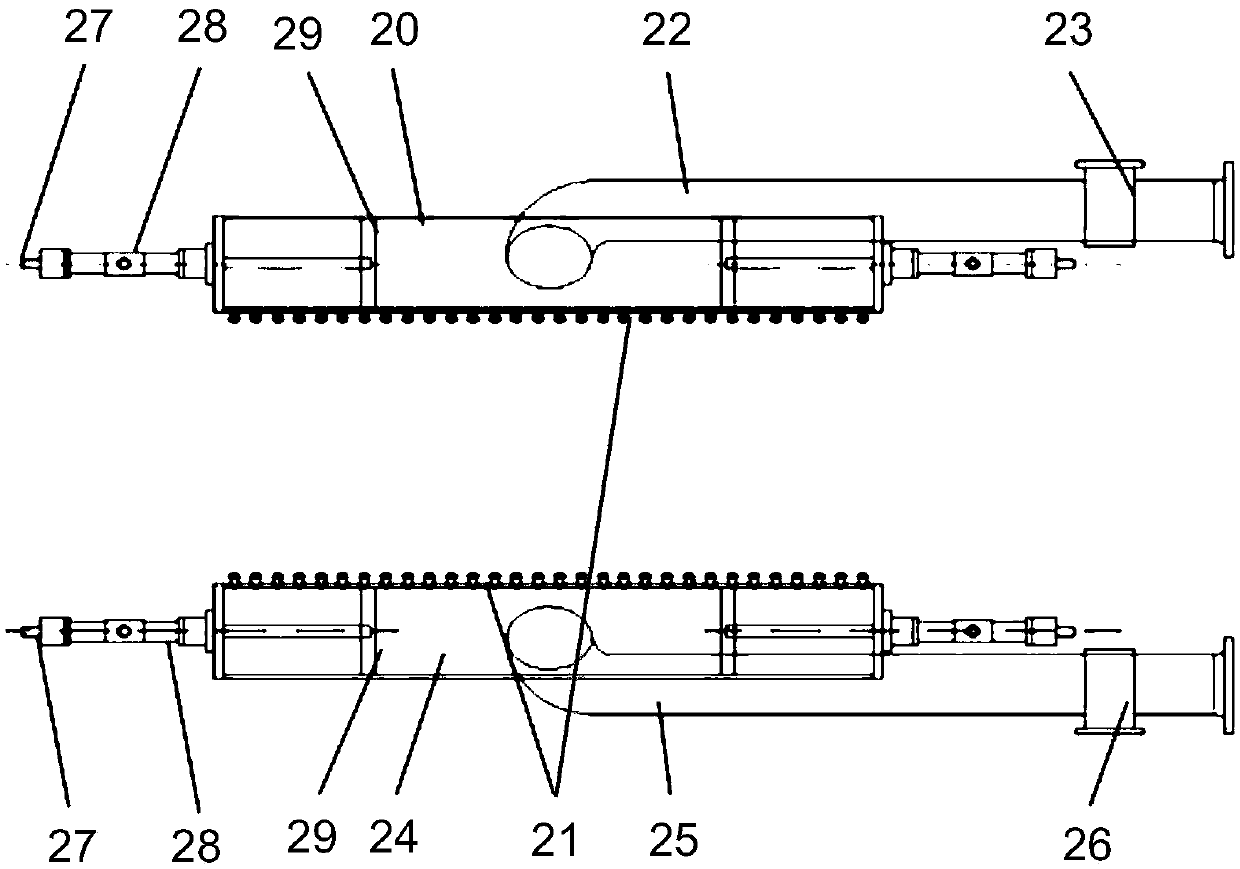

[0039] Please combine Figure 3 to Figure 4 As shown, an energy-saving segmented rack water header device provided by the present invention includes: a rack water header, and the rack water header mainly includes: an upper rack water header 20, an upper rack water header Several nozzles 21 are evenly distributed on the water header 20, connected to the upper frame water inlet pipe 22 at the middle position of the upper frame water header 20, the upper water inlet pipe clamp 23 for fixing the upper frame water inlet pipe 22, and Respectively with the lower frame water header 24, the lower frame water inlet pipe 25, the lower water inlet pipe clamp 26 arranged in mirror image symmetry with the upper frame water header 20, the upper frame water inlet pipe 22, and the upper water inlet pipe clamp 23, the lower machine Several noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com