A Fast Dynamic Adaptive Method for Hot Rolling Width Model

A dynamic self-adaptive, width technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problems of not being able to eliminate the width control deviation, low strip width control accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

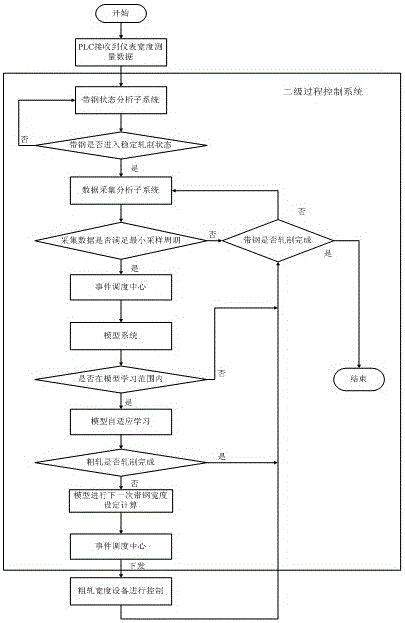

[0037] see figure 1 , a hot rolling width model fast dynamic adaptive method, the method includes the following steps, 1) after the strip passes through the equipment in the finishing rolling area and the width instrument at the exit of the finishing mill, the instrument detects the strip width, and then the instrument The detection periodically sends the corresponding width data to the first-level PLC system;

[0038] 2) After receiving the instrument data, the first-level PLC system sends the corresponding measurement width data to the second-level process control system with a fixed communication cycle;

[0039] 3) The strip state subsystem in the secondary process control determines the length of the strip entering stable rolling and the minimum sampling period according to the distance between the two stands, the thickness of the intermediate billet, the thickness of the finished product, and the rolling speed of the last stand ; The calculation method in this step is as...

Embodiment 2

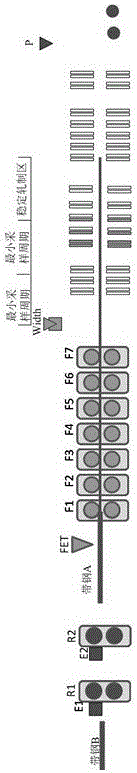

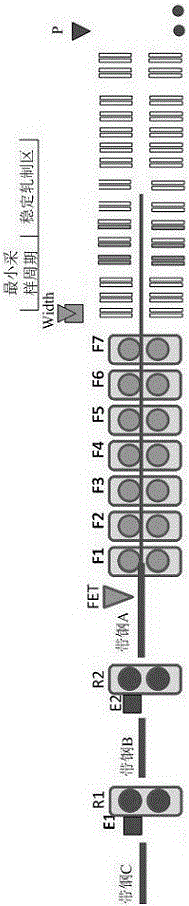

[0055] Strip A, when the head of the strip passes through the Width instrument, it sends data to the PLC system, and the PLC sends the corresponding width data to the secondary process control system, and the secondary strip status subsystem determines the stable rolling of the strip according to the formula (1). The measurement length is 55 meters, and the minimum sampling period determined by the formula (2) is 5.5 seconds, such as image 3 As shown, the first data collection is completed. The rolling stable area is 55 meters and the minimum data collection period is 5.5 seconds. Since the rolling speed is 10m / s at a constant speed, the minimum detection cycle length is also 55 meters. Assuming that the instrument The sampling period is 0.1 second, and the minimum data collection volume is determined to be 55 sampling points. After the data collection system checks the data, the average value is calculated assuming that the average width is 1280mm. After the model receives th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com