Pigment comprising microelement additive and preparation method of pigment

A technology of trace elements and additives, applied in the direction of coating, etc., can solve the problems of uneven dispersion, affecting product quality, unstable color, etc., and achieve the effect of large dosage, good product effect and suitable for popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

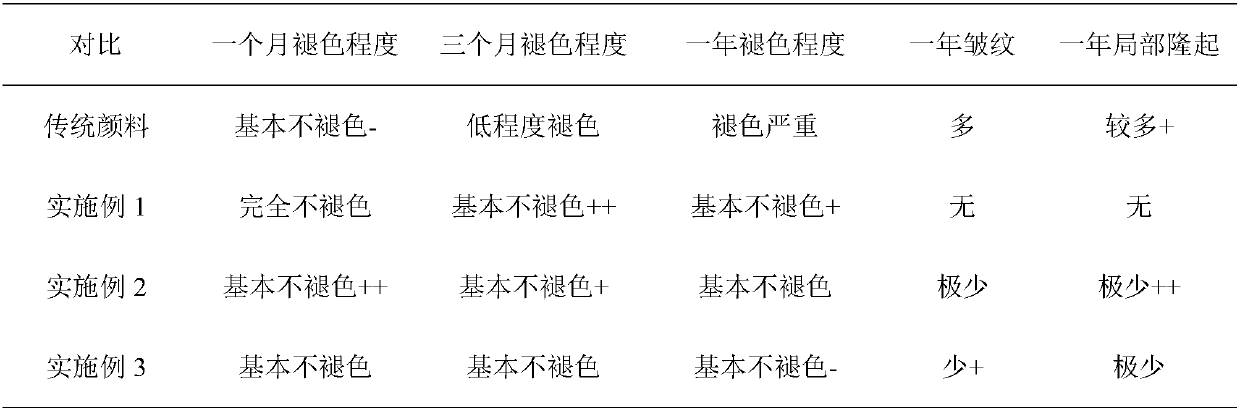

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned pigment with trace element additives comprises the following steps:

[0028] Step 1: Slowly inject dilute sulfuric acid into a reactor filled with iron, after the reaction is complete, dry or dry the obtained precipitate, and recycle to obtain pickling red;

[0029] Step 2: Grinding the above-mentioned acid-washed red and natural red respectively, and then collecting powder products respectively;

[0030] Step 3: Mix pickling red powder and natural red powder according to the formula ratio, stir evenly, and then transfer to the screw conveyor, and add dispersant and suspending agent uniformly in proportion during the conveying process, and the dispersant and suspending agent are powder shape or small granular state;

[0031] Step 4: Then transfer to a pulverizer for further mixing and pulverization. After 8-15 minutes, pass through a 3500-3800 mesh sieve to obtain the product and pack it.

[0032] Among them, the grinding ...

Embodiment 1

[0034] To produce 100kg of pigment, first weigh 4kg of natural red, 0.6kg of dispersant, and 0.4kg of suspending agent. Then follow the steps below:

[0035] Step 1: Slowly inject dilute sulfuric acid into a reactor filled with iron, and after the reaction is complete, dry the obtained precipitate to recover and obtain pickling red;

[0036] Step 2: Weigh 95 kg of the pickling red obtained above, then grind 95 kg of pickling red and 4 kg of natural red with a grinder with a grading sheet, and then use a gyrator to collect powder products;

[0037] Step 3: Mix the pickling red powder and natural red powder, stir evenly, then transfer to the screw conveyor, add 0.6kg dispersant and 0.4kg suspending agent evenly in proportion during the conveying process, the state of dispersant and suspending agent is the best Preferably in powder or small particle state;

[0038] Step 4: Transfer the mixture obtained in Step 3 into a pulverizer for further mixing and pulverization. After abou...

Embodiment 2

[0040] To produce 100kg of pigment, first weigh 3kg of natural red, 0.5kg of dispersant, and 0.5kg of suspending agent. Then follow the steps below:

[0041] Step 1: Slowly inject dilute sulfuric acid into a reactor filled with iron, and after the reaction is complete, dry the obtained precipitate to recover and obtain pickling red;

[0042] Step 2: Weigh 96 kg of the pickling red obtained above, then grind 96 kg of pickling red and 3 kg of natural red with a grinder with a grading sheet, and then use a gyrator to collect powder products;

[0043] Step 3: Mix the pickling red powder and natural red powder, stir evenly, then transfer to the screw conveyor, add 0.5kg dispersant and 0.5kg suspending agent evenly in the process of conveying, the state of dispersant and suspending agent is the best Preferably in powder or small particle state;

[0044] Step 4: Transfer the mixture obtained in Step 3 into a pulverizer for further mixing and pulverization. After about 12 minutes, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com