Production facility and method for high-intensity packing steel belt

A production equipment and high-strength technology, applied in metal processing equipment, workpiece surface treatment equipment, metal rolling, etc., can solve the problem of unstable water mist-air cooling process, poor surface quality and thickness accuracy of steel strip, and equipment cost and high production costs, to achieve the effect of improving surface quality, plate shape and thickness accuracy, high core strength, and reducing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

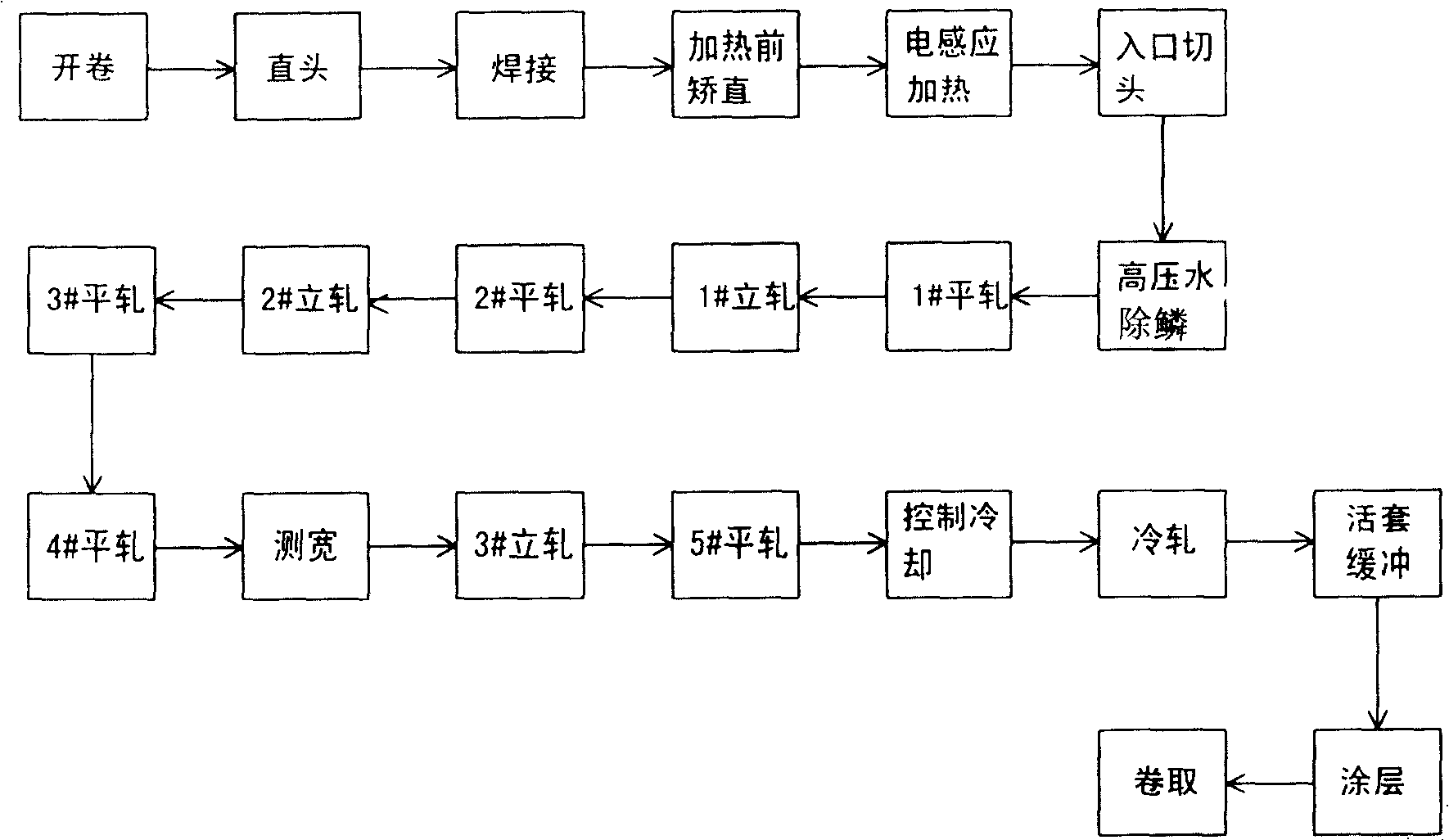

[0040] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0041] Such as figure 1 Shown, according to the production equipment of high-strength packaging steel strip of the present invention, comprise raw material preparation equipment, heating furnace, cropping shears, hot rolling mill, cooling section, coating device, winding equipment, conveying equipment, it is characterized in that the The heating furnace described is an electric induction fast heating furnace 5, and the described production equipment includes raw material preparation equipment arranged in sequence, an electric induction fast heating furnace 5, a hot rolling mill entrance shear 6, a high-pressure water descaling device 7, a first Horizontal hot rolling mill 8, first vertical hot rolling mill 9, second horizontal hot rolling mill 10, second vertical hot rolling mill 11, third horizontal hot rolling mill 12, fourth Horizontal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com