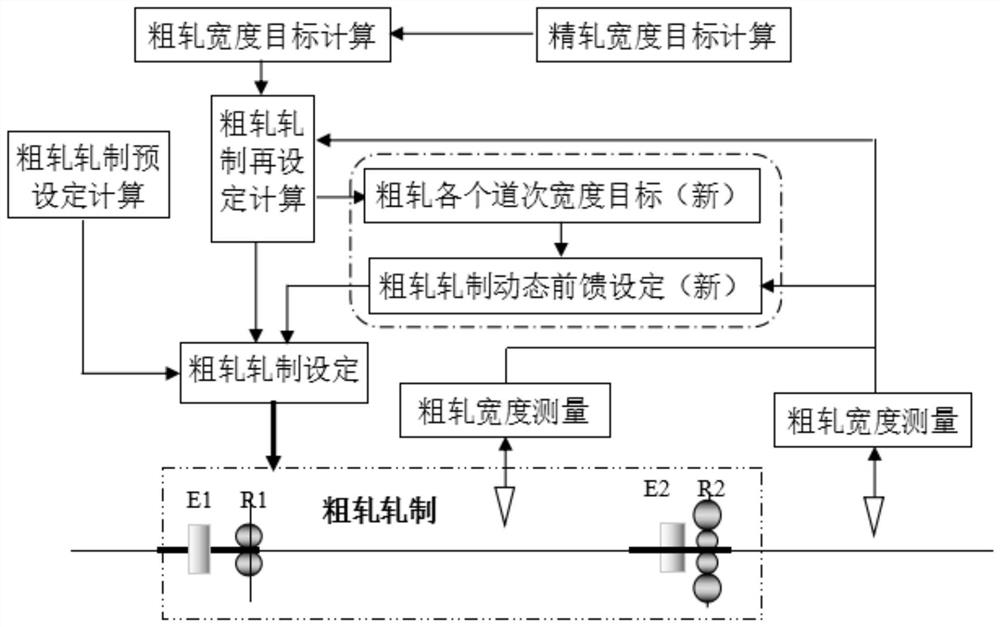

A Dynamic Feedforward Control Method for Rough Rolling Width

A control method and dynamic feed-forward technology, applied in rolling mill control devices, metal rolling, metal rolling, etc., can solve problems such as difficulty in eliminating width, large deviation, uneven strip length along the entire length, etc., and achieve width blockade. The effect of volume reduction, improvement precision, and width control precision improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

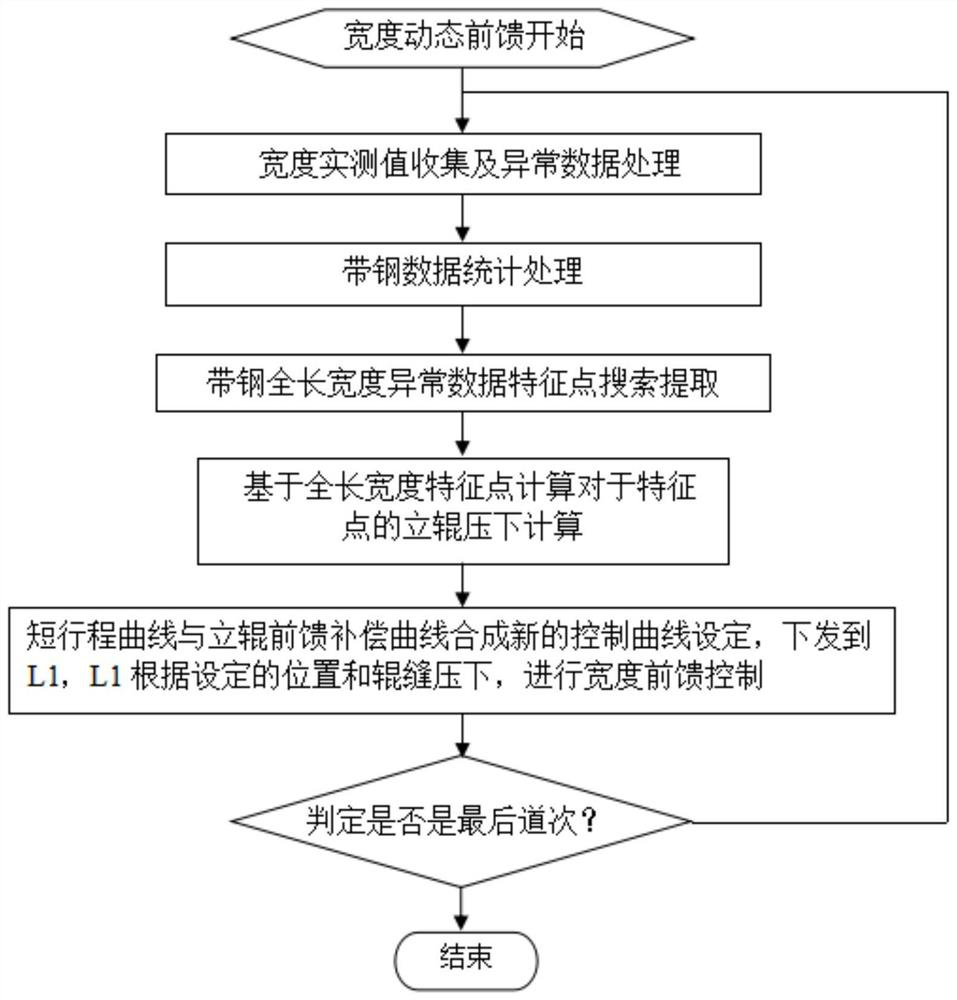

Method used

Image

Examples

Embodiment 1

[0105] With steel inlet thickness: passentrythick = 133.02;

[0106] The amount of subsequent road roller pressure: edraft = 38.9;

[0107] Frequency width mean: widthactmean = 853.55;

[0108] Feeling temperature: TEMP = 1101.13;

[0109] Roller roller diameter: ediam = 930.25;

[0110] Horizontal roller pressure: rdraft = 39.3;

[0111] Horizontal roller diameter: rDIAM = 1158.68;

[0112] General short long control curve:

[0113] Head short line control opening degrees: Head = 3.0, 4.0, 5.0, 5.0, 4.0, 4.0, 3.0, 2.0, 1.0, 0

[0114] Head short drum control length: LengthHead = 1050.0

[0115] The tail short-length control opening degree: tail = 3.0, 3.0, 2.0, 2.0, 2.0, 2.0, 0.0, 0.0, 0.0, 0.0

[0116] Tail short turtle control length: Lengthtail = 2500.0

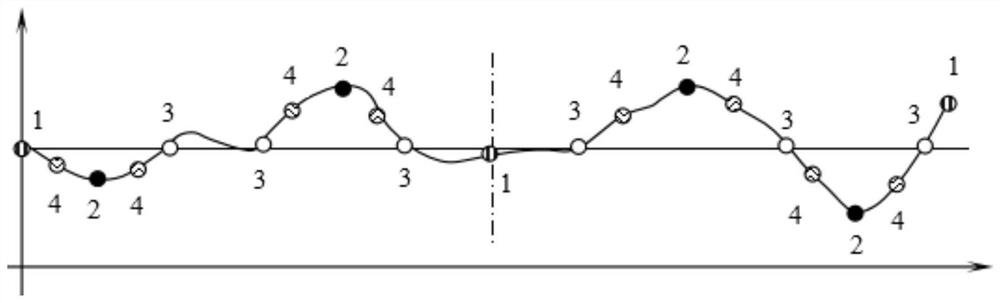

[0117] (1) Rough rolling the first rack of the third measurement width curve:

[0118] Tape steel measured width data graph Figure 6 Distance

[0119] (2) Width statistics and abnormal classification decisions:

[0120] Widt...

Embodiment 2

[0125] With steel entrance thickness: passentrythick = 161.02

[0126] Subsequent road roller pressure: edraft = 32.8

[0127] Width mean: widthactmean = 853.55

[0128] Feeling temperature: TEMP = 1091.13

[0129] Roller roller diameter: ediam = 930.25

[0130] Level roller pressure: rdraft = 30.47

[0131] Horizontal roller diameter: RDIAM = 1158.68

[0132] General short long control curve: Figure 11 , Figure 12 Indicated.

[0133] (1) Rough rolling the first rack third first measured width curve: strip steel measured width data curve Figure 13 Indicated.

[0134] (2) Width statistics and abnormal classification decisions: Width mean: 1253.067, mean square difference: 0.43, width data distribution Figure 14 The number of widths: 1249.25. By comparing the width distribution determination, the width actual value is not a normal distribution, and there is abnormal uneven width.

[0135] (3) Through the data processing, find the steel head, the tail width abnormality, acquire t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com