A head and tail width control method for variable step distance of a fixed width machine

A technology of width control and width fixing machine, which is applied in the direction of metal rolling stand, metal rolling mill stand, etc., and can solve the problems of ineffective control of the width of the head and tail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

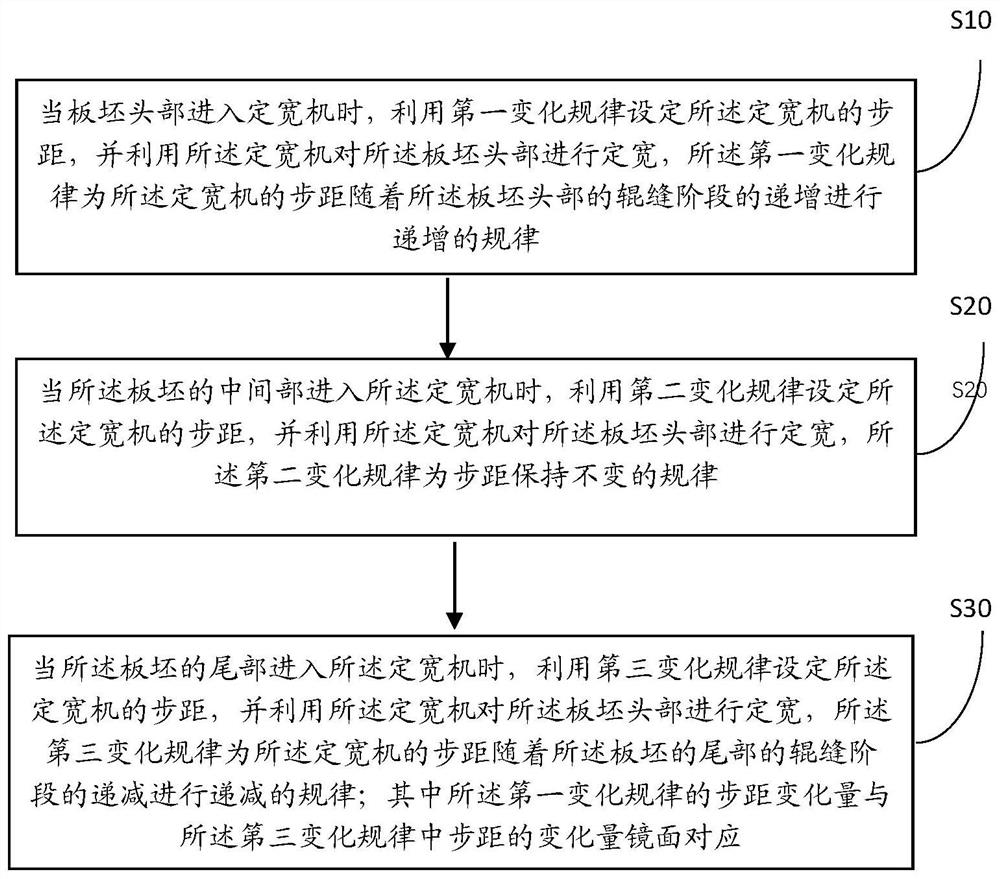

[0032] figure 1 It is a schematic flow chart of a head and tail width control method with variable step pitch for a fixed-width machine in an embodiment of the present invention. The embodiment of the present invention provides a head-to-tail width control method with variable step distance for a fixed-width machine, please refer to Figure 1-4 , the method includes:

[0033] Step 10: When the head of the slab enters the width-fixing machine 1, use the first change law to set the step distance of the width-fixing machine 1, and use the width-fixing machine 1 to measure the head of the slab 2 Width, the first change law is the law that the step distance of the width-sizing machine 1 increases in multiple stages with the increase of the roll gap stage at the head of the slab 2 .

[0034]Further, the slab head is divided into multiple stages according to the roll gap, at least including: the primary roll gap of the head, the secondary roll gap of the head, and the tertiary roll...

Embodiment 2

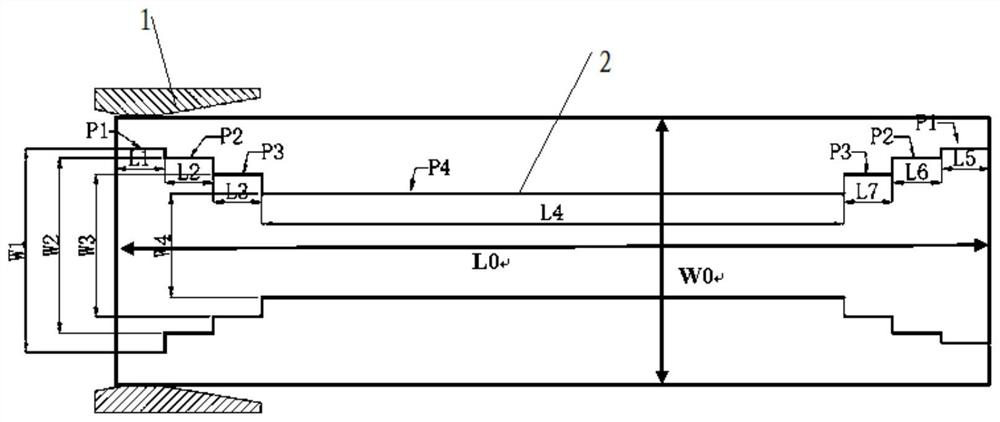

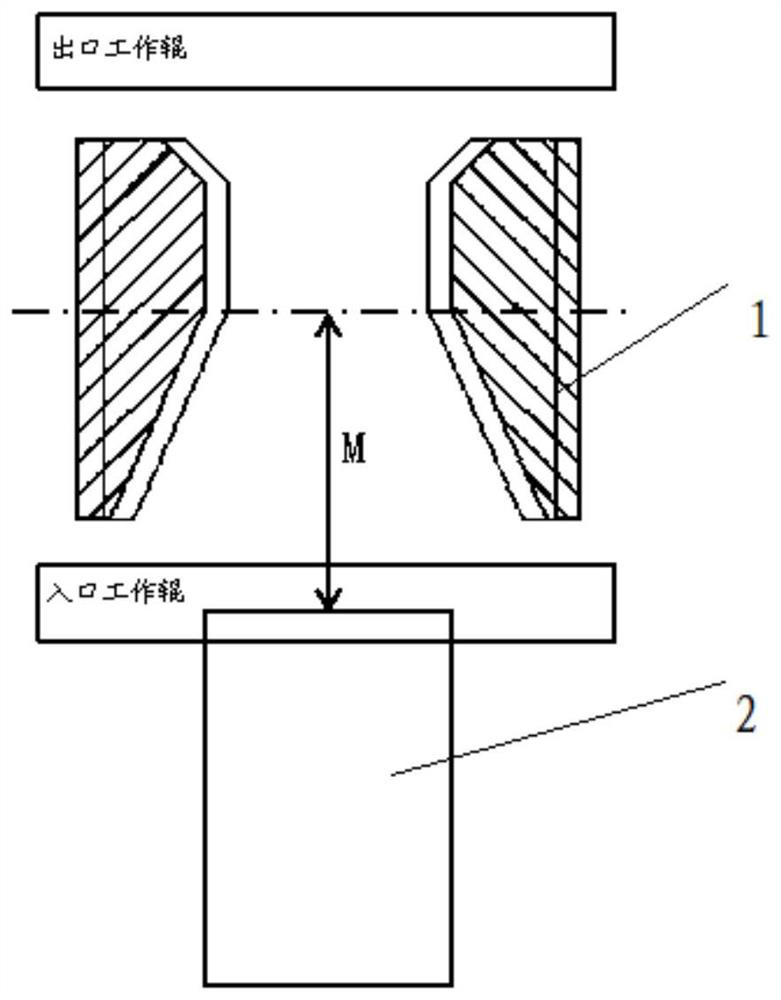

[0053] In order to better introduce the technical characteristics and application of a head-to-tail width control method with variable step distance for fixed-width machines of the present invention, the application of the present invention will be described in detail below in conjunction with specific embodiments. Please refer to Figure 5-7.

[0054] The embodiment of the present invention is a specific application of a hot rolling mill using a head-to-tail width control method of the present invention with a variable step pitch for a fixed-width machine. The pipeline steel X80 with a higher hardness level and a larger amount of width reduction is selected for testing. The test volume 20 pieces. Raw material specification: 230*1650*10000, finished product specification: 22*1450mm, the theoretical width reduction amount of fixed width machine 1 is 200mm, the actual width reduction amount is 245mm, the step distance of fixed width machine 1 is set to P1=100mm, P2=P3=200mm, P4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com