A Method of Width Model Control Using Roll Gap Value of Side Guide Plate

A technology of model control and roll gap value, which is applied in the field of steel rolling, can solve the problems of low model control accuracy and width measurement distortion, and achieve the effect of improving width control accuracy and strip yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiment of the present application solves the technical problems of width measurement distortion and low precision of model control in the prior art by providing a method of using the roll gap value of the side guide plate for width model control; it achieves the improvement of data measurement accuracy, and further improves the The technical effect of width control accuracy and strip yield.

[0024] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

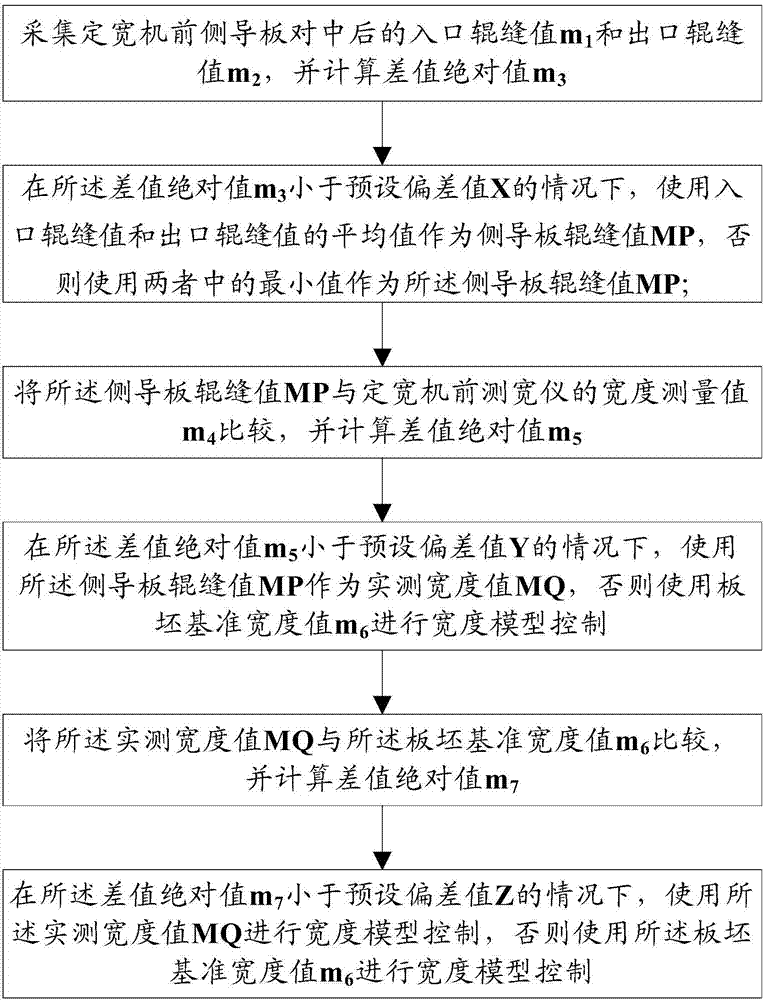

[0025] A method for controlling a width model by using a roll gap value of a side guide plate, comprising the following steps:

[0026] Collect the entrance roll gap value m after the front side guide plate of the sizing machine is centered 1 and exit roll gap value m 2 , and calculate the difference between the two, and further calculate the absolute value of the difference m 3 ;

[0027] In the absol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com