Device for tracing and detecting interior plate blank head position of fixed width machine

A head position, tracking and detection technology, which is applied to rolling mill control devices, metal processing equipment, metal rolling, etc., can solve problems such as bad slab shape and abnormal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

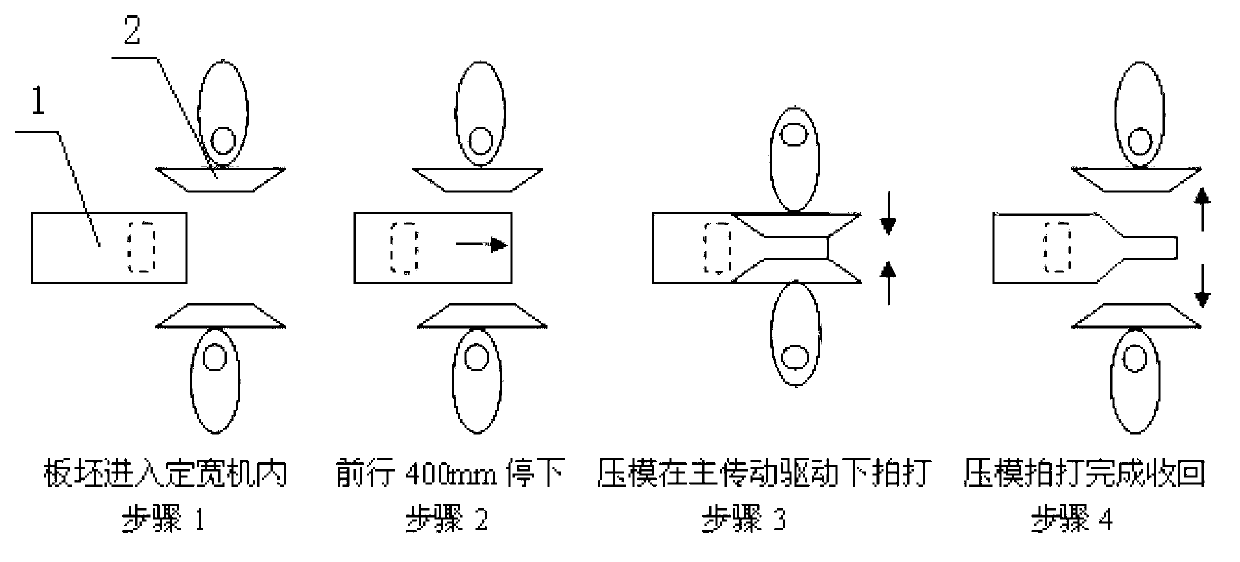

[0019] figure 1 It is a schematic diagram of the side pressing die and slab movement (top view) of the fixed-width machine.

[0020] In the figure: the side pressing die 2 and the slab 1 of the sizing machine.

[0021] Step 1) The slab enters the starting position of the sizing machine;

[0022] Step 2) The slab moves forward with a die size of 400mm and stops;

[0023] Step 3) The main drive motor rotates from 180 degrees to 360 degrees or 0 degrees, and the die 2 beats the slab 1 once;

[0024] Step 4) After the beating is completed (the main drive motor rotates from 360 degrees (0 degrees) to 180 degrees, the stamper retracts.

[0025] Entering the next cycle of beating, the rectangle in the middle represents the incoming slab 1, and its arrow represents the stepping forward of the slab; the trapezoid on both sides represents the die 2, and its arrow represents its beating direction, reciprocating motion; the upper and lower ellipses represent the main drive motor Drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com