A control method for preventing strip breakage in thin strip steel cold rolling process

A control method and technology for thin strip steel, applied in rolling mill control device, metal rolling, metal rolling and other directions, can solve the problems of low detection accuracy, high cost of detection equipment, affecting the control accuracy of strip thickness, etc., to achieve improved control Accuracy, improved stability and yield, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

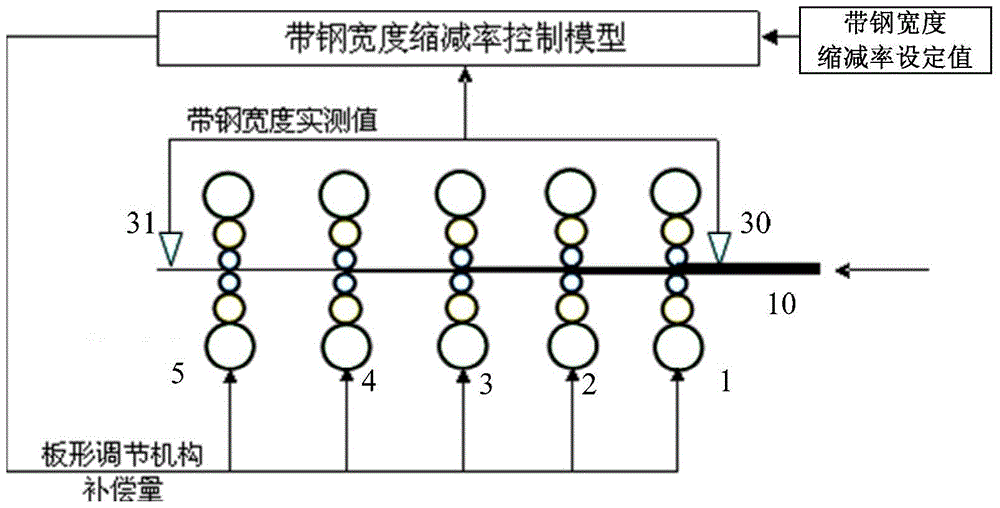

[0050] An embodiment of the control method for preventing strip breakage in the thin strip steel cold rolling process of the present invention is as follows figure 1 As shown, this embodiment is used in the rolling process control system of the five-stand cold rolling mill. In this embodiment, at the entrance and exit of the cold-rolling unit composed of 5-stand rolling mills, an entrance strip width detector 30 and an exit strip width detector 31 are respectively configured to detect in real time the entrance and exit of the cold-rolling unit along the strip width. The measured value of the width at each position in the length direction of 10. The control process includes the following steps:

[0051] (a) According to the steel type, thickness, width and rolling process parameters of the strip, determine the given value R of the width reduction rate after rolling by all stands of the cold rolling mill w_set ;Width reduction rate given value R w_set It can be obtained throu...

Embodiment 2

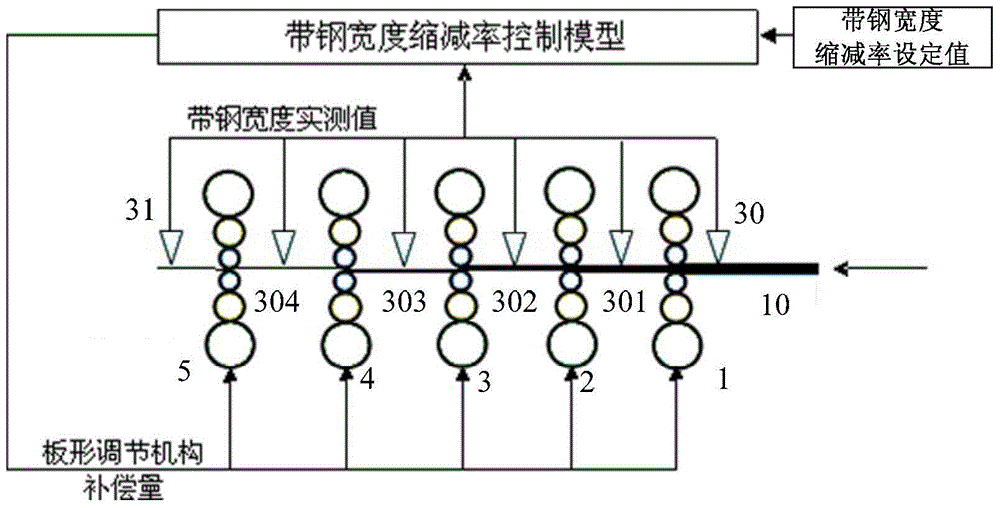

[0067] Another embodiment of the control method for preventing strip breakage in the thin strip steel cold rolling process of the present invention is as follows figure 2 As shown, this embodiment is used in the rolling process control system of the five-stand cold rolling mill. In the present embodiment, at the entrance and exit of the cold-rolling unit composed of 5-stand rolling mills, an entrance strip width detector 30 and an exit strip width detector 31 are configured respectively. Between 5, strip steel width detectors 301-304 are respectively configured to detect in real time the measured width values at various positions along the length direction of the strip steel 10 between the entrance, exit and between the stands of the cold rolling mill. The control process includes the following steps:

[0068] (a) According to the steel type, thickness, width and rolling process parameters of the strip, through rolling experiments or theoretical model simulation calculatio...

Embodiment 3

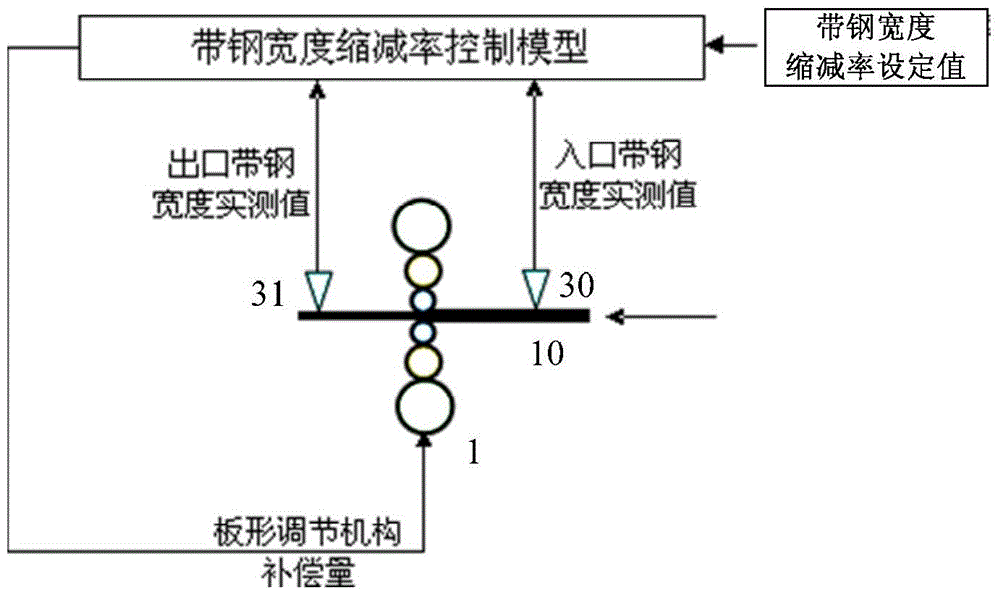

[0084] image 3 It is another embodiment of the control method for preventing strip breakage in the thin strip steel cold rolling process of the present invention, and it is used in a rolling process control system of a cold rolling unit composed of a single stand. In the present embodiment, at the entrance and exit of the cold-rolling unit consisting of single-stand rolling mills, an entrance strip width detector 30 and an exit strip width detector 31 are respectively configured to detect in real time the entrance and exit of the cold-rolling unit along the strip 10 The measured value of the width at each position in the length direction of . This embodiment is actually n=1 and β in the above-mentioned multi-stand cold rolling mill i = 1, the control process includes the following steps:

[0085] (a) According to the steel type, thickness, width and rolling process parameters of the strip, determine the given value R of the width reduction rate after being rolled by a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com