Method for setting rolling pressure of hot continuous rough rolling area during rolling by aid of vertical rolls

A technology of vertical roll rolling and rolling pressure, which is applied in the field of rolling pressure setting of vertical roll rolling in the rough rolling area of hot continuous rolling, and can solve the problem of small deformation resistance, small deformation degree, vertical roll rolling pressure setting Inaccurate setting and other problems, to improve the rolling pressure setting accuracy, improve the effect of control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

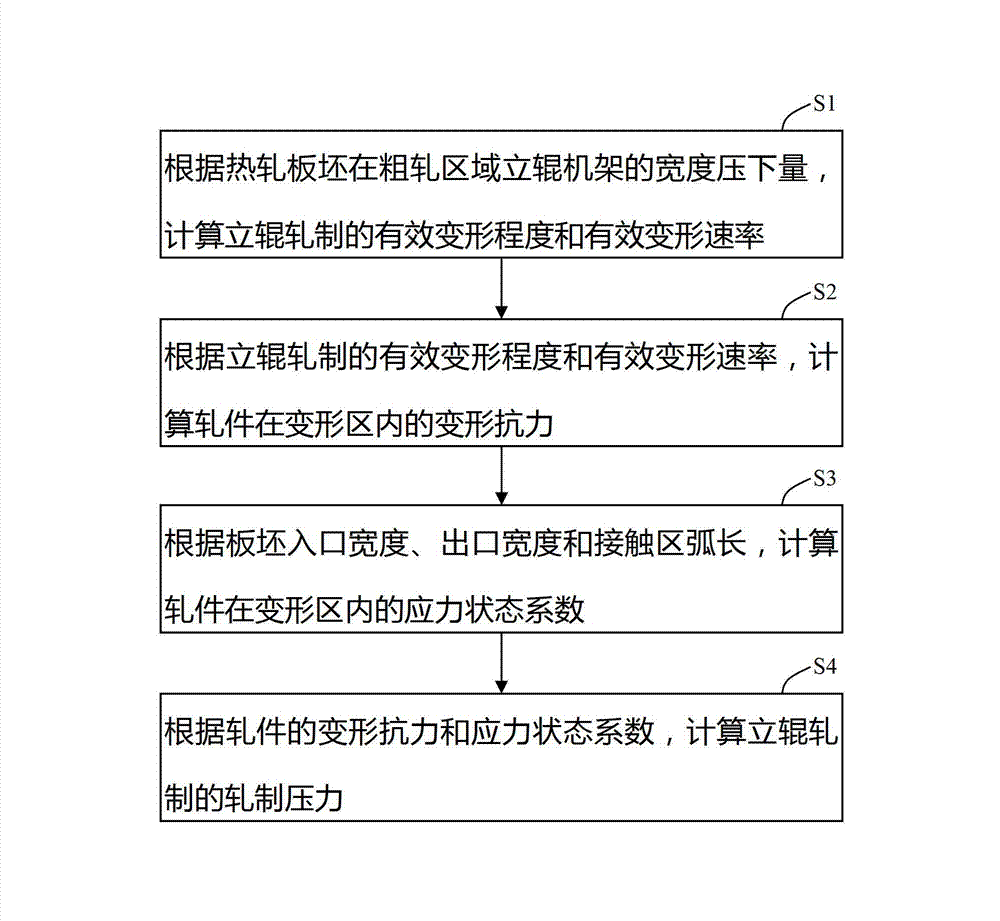

[0094] The rolling pressure setting method of the vertical roll rolling in the hot continuous rolling rough rolling area of the present invention is used to roll the slab five times, and the specific steps are as follows:

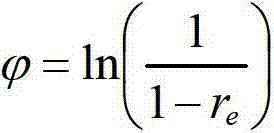

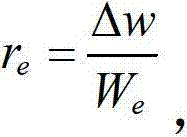

[0095] Step 1. Calculate the effective deformation degree and effective deformation rate of the vertical roll rolling according to the width reduction of the vertical roll stand of the hot-rolled slab in the rough rolling area. The specific data are shown in Table 1.

[0096] Table I:

[0097]

[0098] Step 2. Calculate the deformation resistance of the rolled piece in the deformation zone according to the effective deformation degree and effective deformation rate of the vertical roll rolling. See Table 2 for specific data.

[0099] Table II:

[0100]

[0101]

[0102] Step 3. Calculate the stress state coefficient of the rolled piece in the deformation zone according to the slab entrance width, exit width and arc length of the contact zone. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com