A method for automatic control of strip width in cold rolling process

A strip width technology, applied in the field of automatic control, can solve problems such as no consideration, strip edge fracture, waste products, etc., and achieve the effect of reducing cross section and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

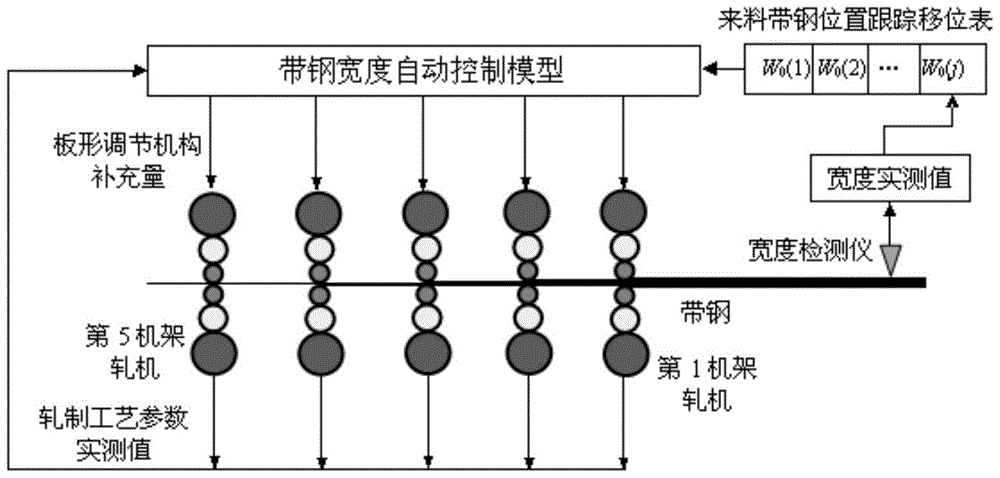

[0067] figure 1 In this technical scheme, a strip width detector is installed at the entrance of the cold tandem rolling mill to detect in real time the measured width values at various positions in the length direction of the hot-rolled incoming material strip at the entrance of the cold-rolled mill, and calculate the actual measured value and the width of the hot-rolled incoming material. The difference between the set values is distributed to each rack according to a certain ratio, and the variation of incoming strip width that needs to be eliminated by each rack is obtained.

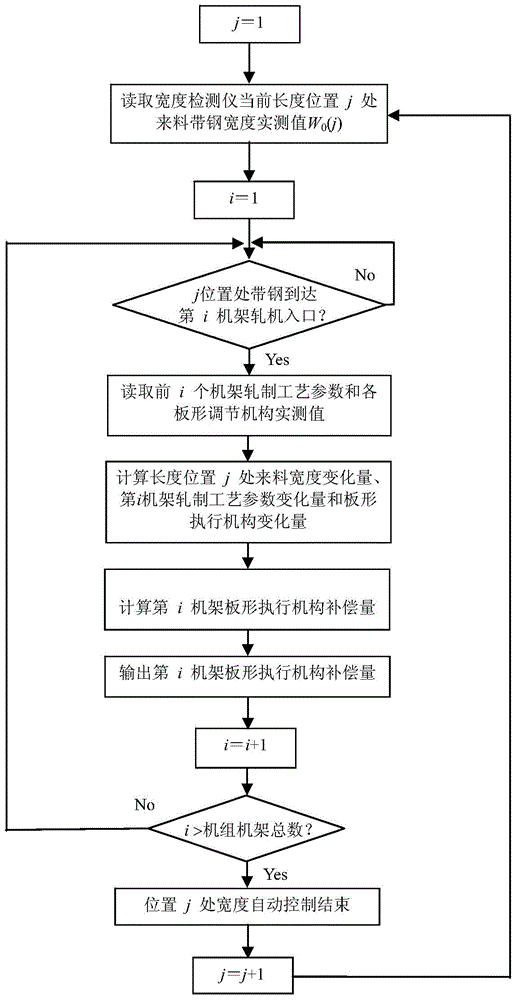

[0068] figure 2 In this technical solution, after establishing the strip width prediction model at the outlet of each rack, set the parameter j to 1, and then read the actual measured value W of the incoming strip width at the current length position j of the width detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com