Electromechanical integrated device and extrusion method for extruding rubber products

A technology of rubber products and extrusion heads, which is applied in the field of mechatronics and extrusion, can solve the problems of poor extrusion accuracy, inability to adjust errors in time, and poor anti-disturbance ability, so as to ensure accuracy and improve anti-disturbance Capability and extrusion accuracy, the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The embodiment of the present invention relates to a mechatronics device and extrusion method for extruding rubber products, which are used to realize real-time and intelligent follow-up control and closed-loop control, and ensure the precise extrusion of rubber products. The prerequisite for the application of the present invention is that the product extrusion die must be adjusted according to the "pushing out" extrusion die.

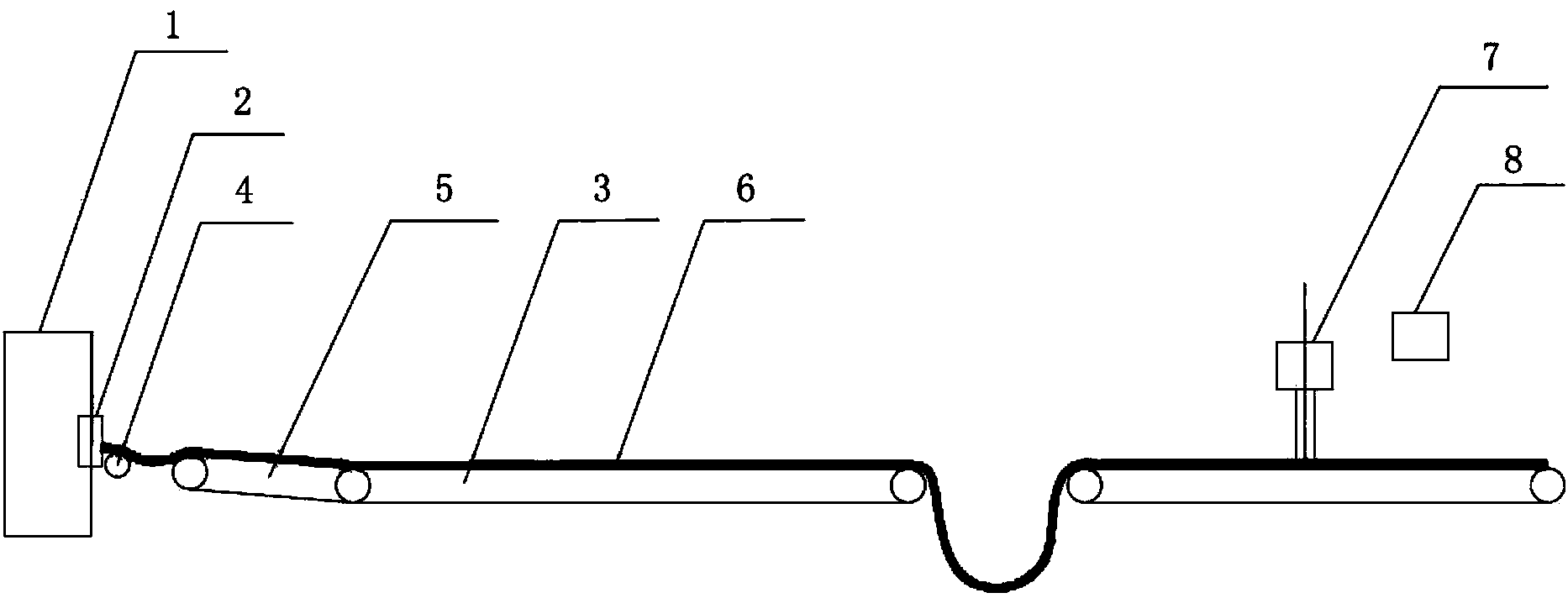

[0055] Such as figure 1 As shown, the embodiment of the present invention is a mechatronics device for extruding rubber products, including an extruder head 1, a receiving device 3, a continuous scale weighing device 7, a width measuring device 8 and a PLC control system, The extruder head 1 is provided with an extrusion die 2, the extrusion die 2 is a push-out extrusion die, and a die speed measuring roller 4 for measuring the extrusion speed is installed on the outside of the push-out extrusion die; a continuous scale weighing device 7 , the...

specific Embodiment approach

[0067] 1. The main ring of speed following servo control: the principle is to detect the linear speed of rubber products in real time through the die-shaped speed measuring roller, which reflects the actual extrusion speed of the product. Using this speed, the linear speed of product extrusion can be compared with that of the rubber product. Direct real-time speed tracking is established between the receiving and receiving line speeds to realize follow-up control to eliminate fluctuations caused by predictable errors such as inherent errors in the equipment itself and changes in rubber properties, so as to ensure accurate extrusion of products. The specific implementation is as follows:

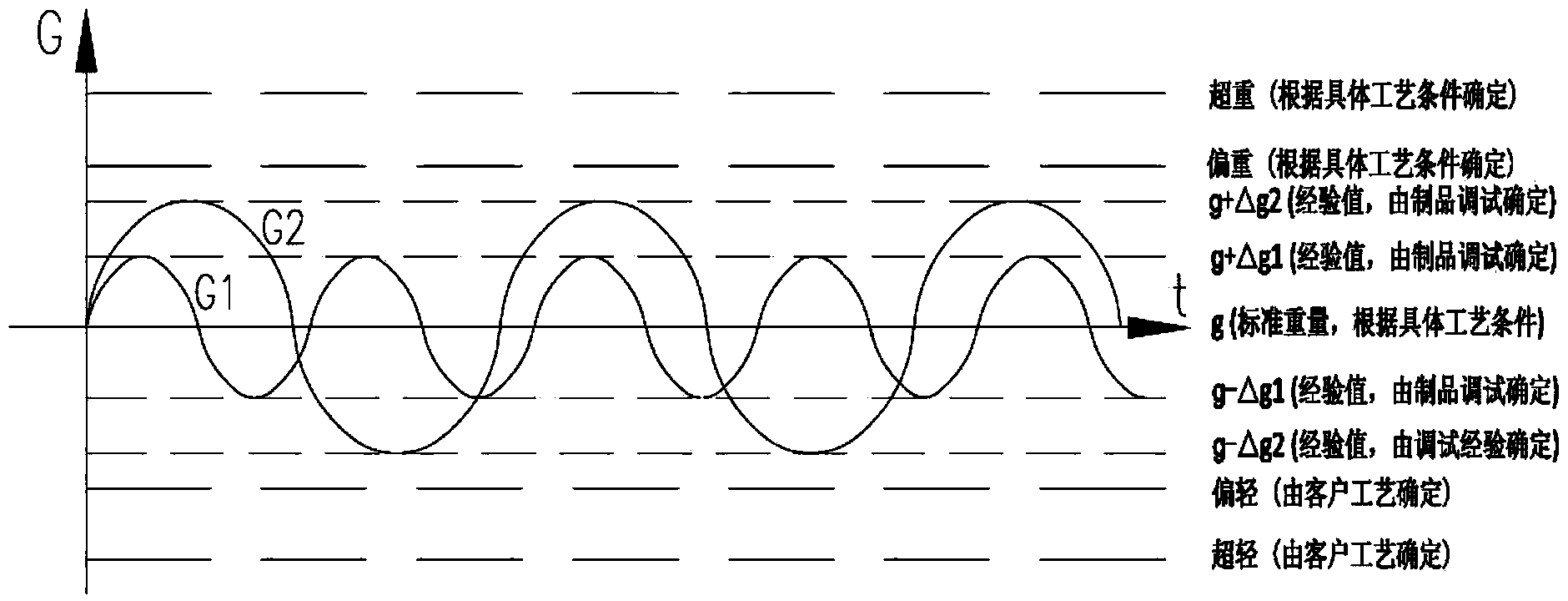

[0068] (1) Parameter setting: set the extruded rubber product to be a synthetic rubber sheet of 100mm×1mm, set the standard weight value g per meter of the rubber product to 0.1kg, and set the standard width value to 100mm. The extrusion line speed of the rubber product is 35m / min, and the no...

Embodiment 2

[0092] A mechatronics device for extruding rubber products in the embodiment of the present invention, only on the basis of embodiment 1, a linkage device is newly added behind the continuous scale weighing device, and the linkage device is used to The rubber products extruded by the extrusion die are subjected to subsequent processing such as shaping. In this embodiment, the linkage device includes an exhaust device, a bridge roller table, an uphill conveyor belt, a cooling device, a downhill conveyor belt, a drying device, and a coiling and / or cutting device connected in sequence.

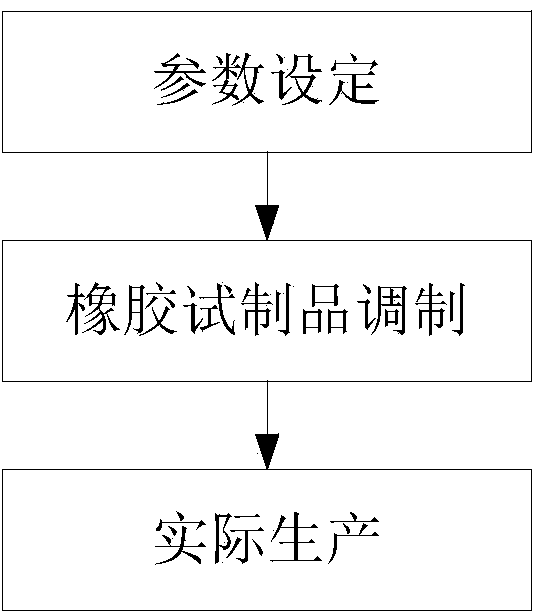

[0093] A kind of rubber product extrusion method of the present embodiment, described extrusion method utilizes described electromechanical integration device, comprises the following steps:

[0094] 1. The main ring of speed following servo control: the principle is to detect the linear speed of rubber products in real time through the die-shaped speed measuring roller, which reflects the actual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com