A strip width control method for hot-rolled wedge-shaped billet

A width control, wedge-shaped billet technology, applied in the direction of metal rolling stands, metal rolling mill stands, etc., can solve the problem that the overall control accuracy of the slab width is not high enough, and achieve the effect of improving the width control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

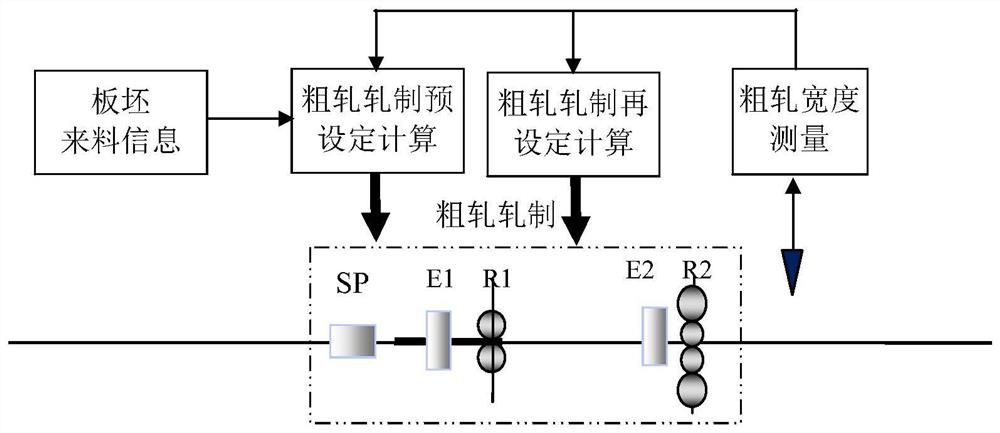

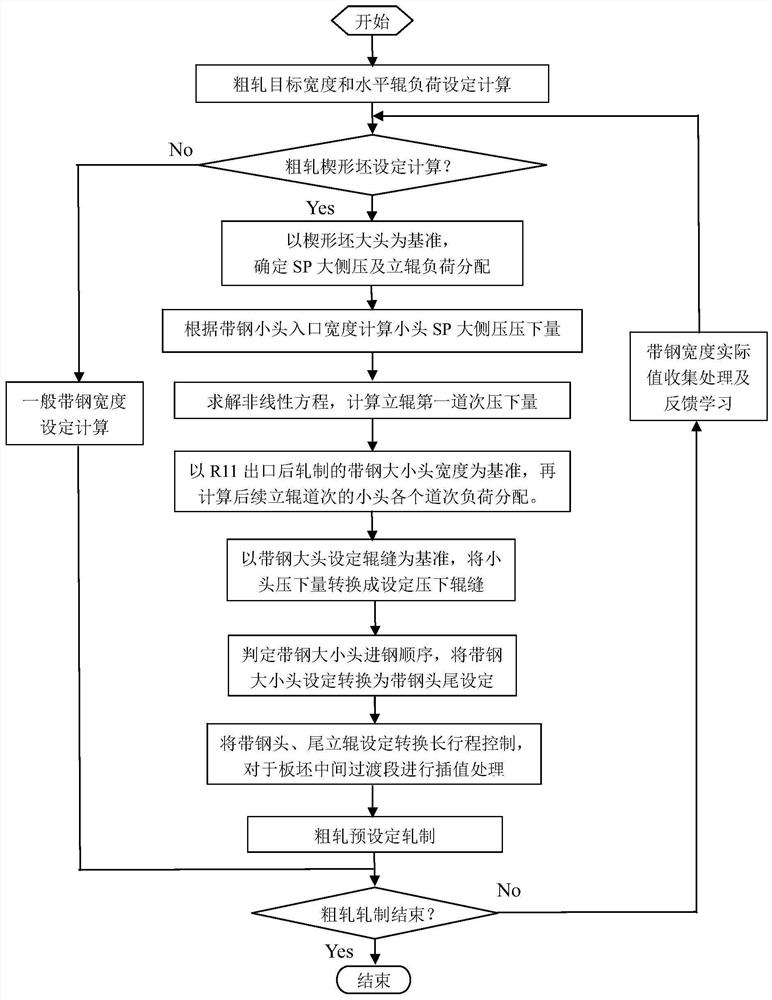

Method used

Image

Examples

Embodiment

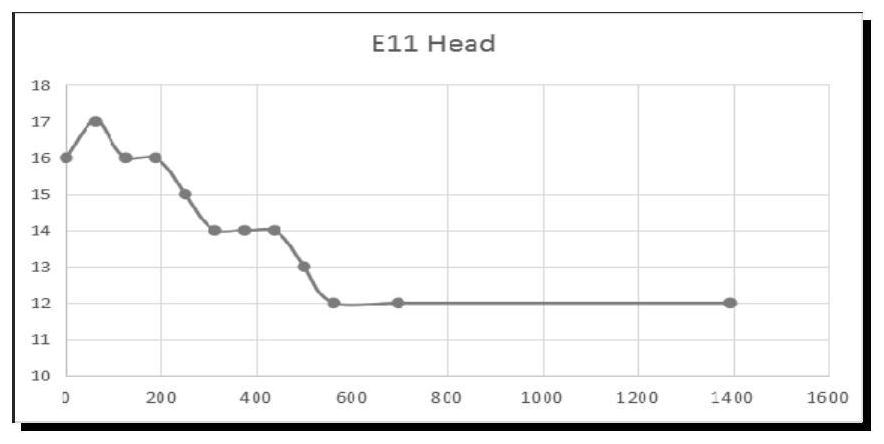

[0079] Actual strip produced (all data in "mm"):

[0080] Inlet Head Width: 1171.072

[0081] Inlet Tail Width: 1242.9044

[0082] Wedge start position: 1200.0

[0083] Wedge End Position: 10630.0

[0084] Slab length: 10760.0

[0085] Incoming material thickness: 222.0

[0086] (1) Calculation of rough rolling target width and horizontal roll load setting:

[0087] Rough rolling target width: 1092.1355

[0088] R1 horizontal roll reduction: 20.295826, 36.111572, 30.270874

[0089] R2 horizontal roll reduction: 34.849052, 33.158211, 25.261719

[0090] (2) Based on the large end of the wedge-shaped billet, determine the load distribution of the SP large side pressure and the vertical roll, and determine the reduction of each pass of the rough rolling large end

[0091] Large side pressure target: 1062.896

[0092] Large side pressure dog bone: 23.430

[0093] Maximum side pressure reduction: 210.74303

[0094] R1 horizontal roll inlet thickness: 242.91177

[0095] R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com