Computer model control method for thickness of hot-rolled product

A width and product technology, applied in the field of computer model control of the width of hot rolled products, can solve the problems affecting the width accuracy and fluctuation of the product, and achieve the effects of improving the control accuracy, narrowing the fluctuation range, and reducing the scrap removal rate and cost loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Seeing table 1 is the original planning data of this embodiment:

[0025] Table 1: Original plan data implementation example table cold ruler value (unit: mm)

[0026] steel type

Number of rolled coils

Product thickness

Product width

Slab Thickness

Slab width

Slab length

General carbon

200 rolls

3.50

<950

230、170

1050

9640

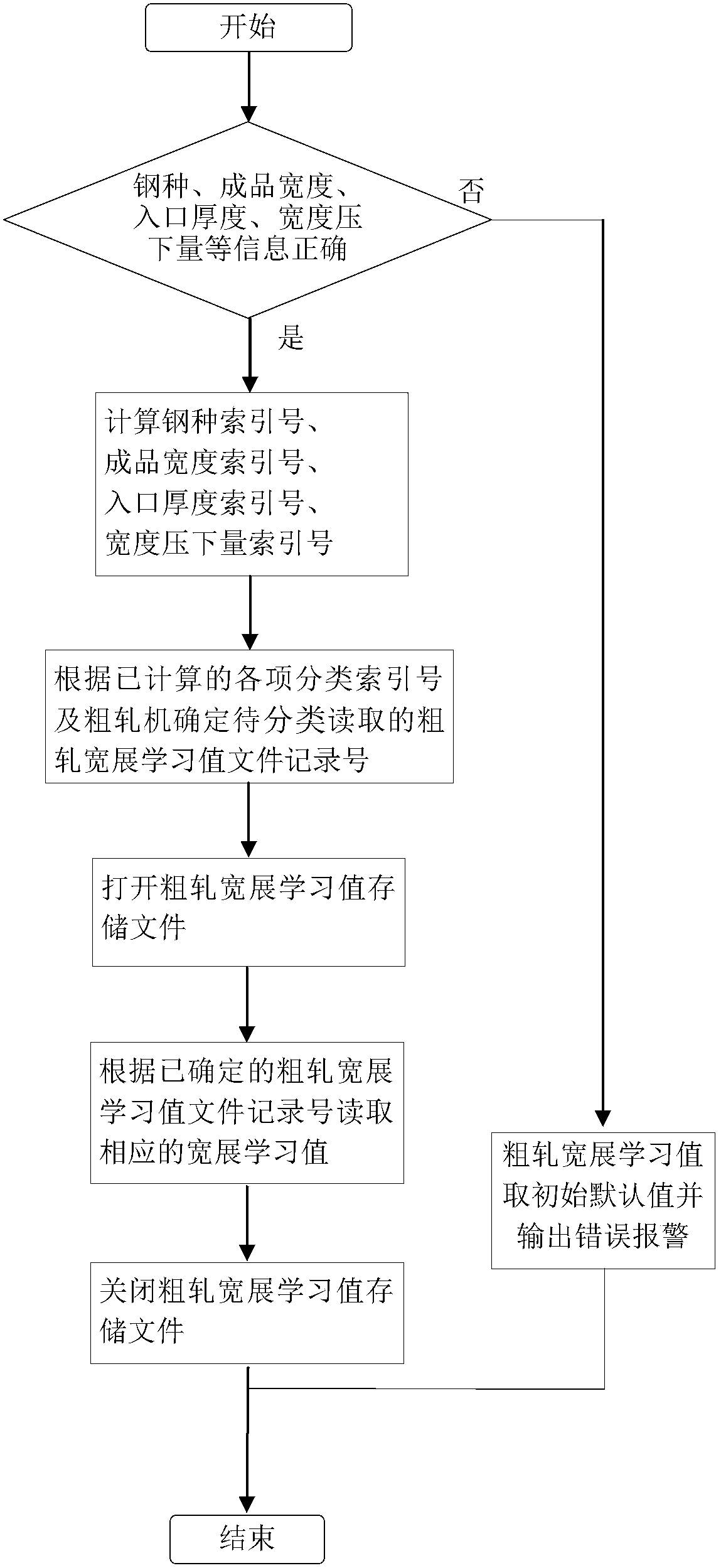

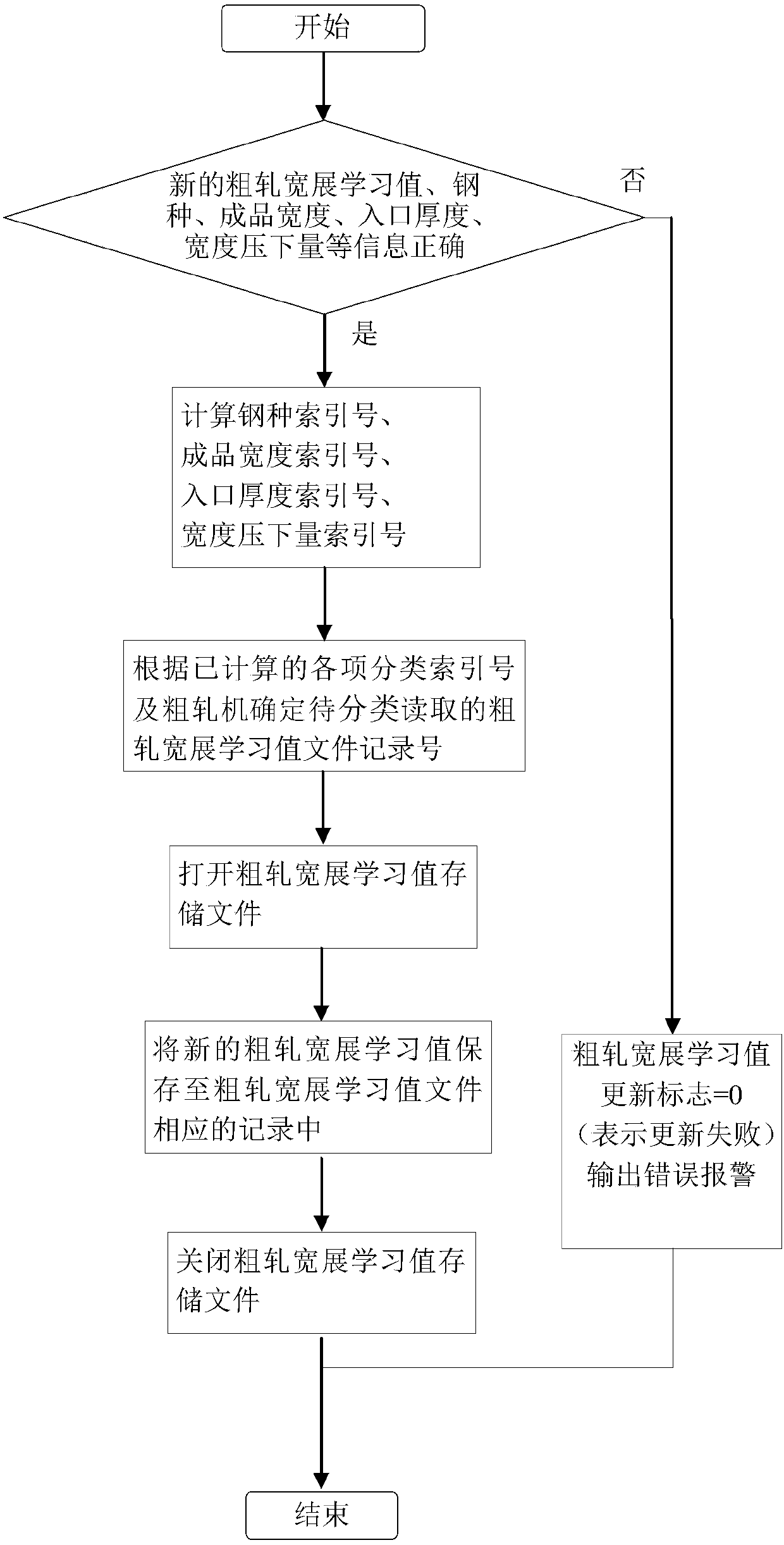

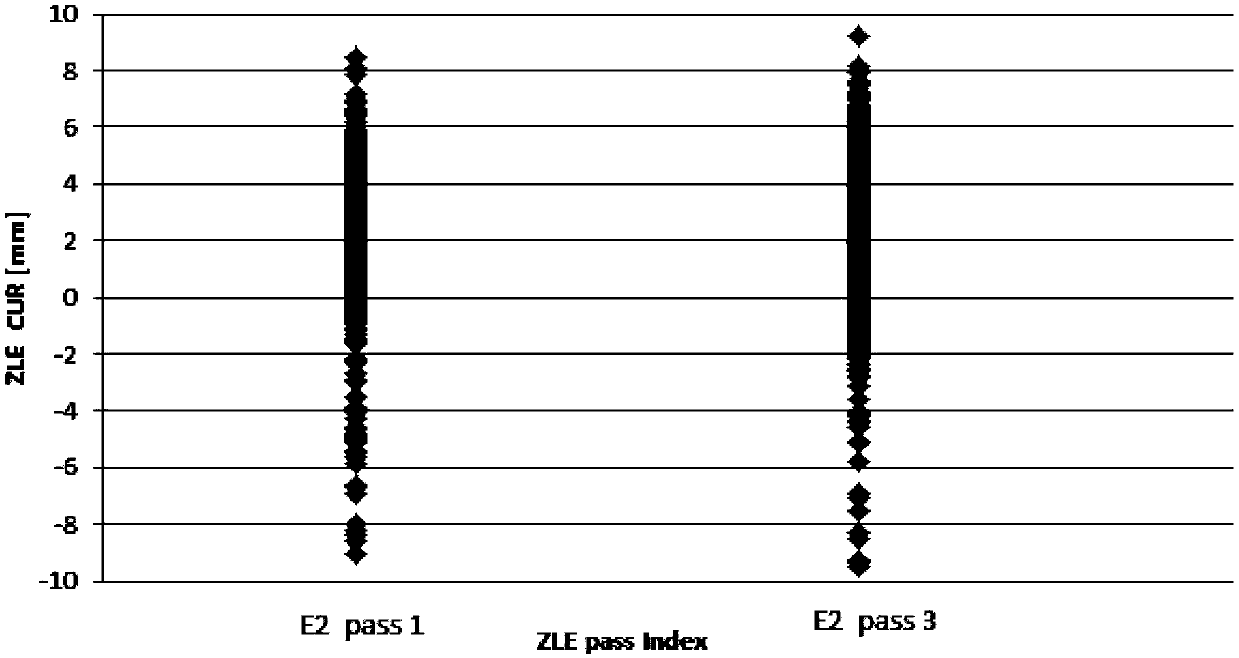

[0027] 1. Taking the No. 2 roughing mill of Line 1780 of a hot-rolled strip mill as an example, the classification reading of the learning value of roughing width expansion and the storage module file records are compared and explained:

[0028] Table 2: the extensive learning value file content (unit: mm) of classification method of the present invention

[0029]

[0030] The classification reading and storage module of rough rolling width expansion learning value reads and stores the corresponding records of the rough rolling width expansion learning file according to the steel ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com