Low-manganese high-carbon steel wire rod for high-strength steel strand and preparation method thereof

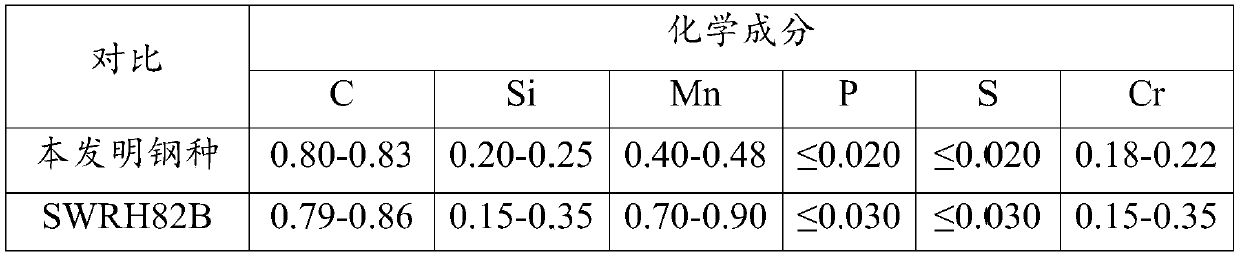

A technology of high-strength steel and high-carbon steel, which is applied in the field of low-manganese and high-carbon steel wire rods for high-strength steel strands and its preparation, and achieves the effects of refining lamella spacing, improving microstructure and mechanical properties, and reducing the degree of central segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

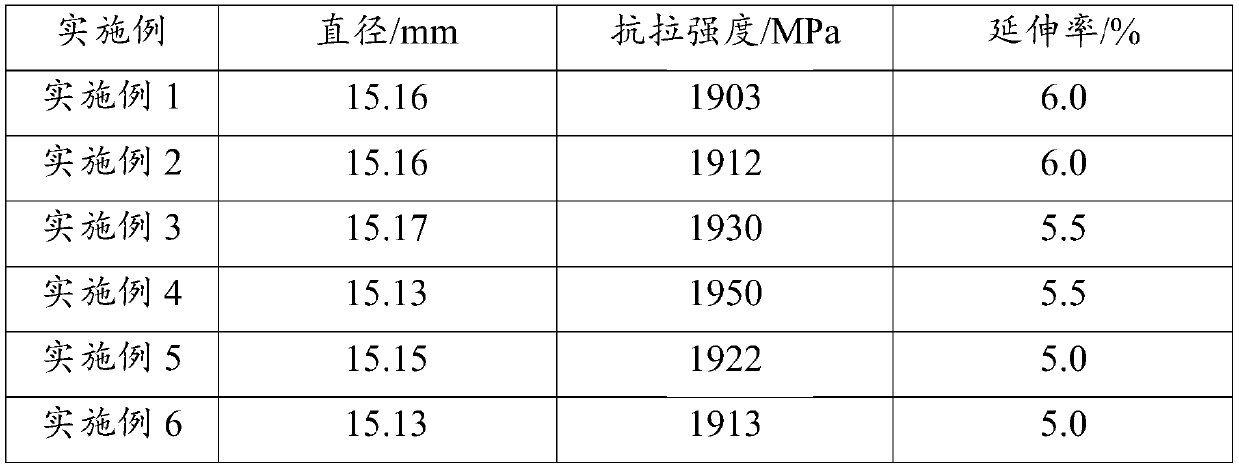

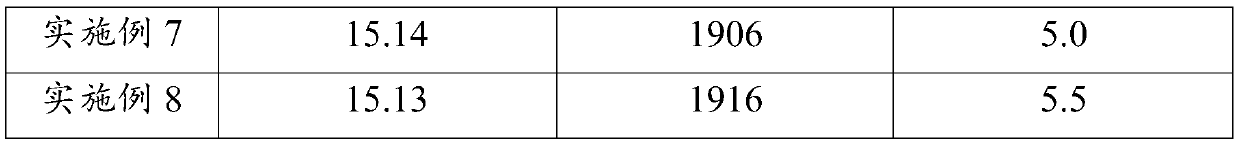

[0028] Embodiment 1-8 The preparation method of low-manganese high-carbon steel wire rod for high-strength steel strand is as follows,

[0029] The heating furnace is used to heat the 140cm*140cm*15.7m continuous casting billet through the heating furnace. The heating temperature of the heating furnace is controlled as follows: preheating section 970±20℃, heating section 1090±20℃, soaking section 1140±20℃, The air-fuel ratio is 0.65±0.05, the heating time is 75±5min, and the rolling start temperature is 1050±15°C;

[0030] 22 passes of continuous rolling, the finish rolling inlet temperature is 950±15℃, and the outlet temperature is ≤1000℃;

[0031] Spinning, the spinning temperature is 920±10°C;

[0032] Stelmore phase change cooling, passing through 12 roller tables with different speeds in sequence, the roller table speeds are 1.280, 1.390, 1.453, 1.527, 1.599, 1.632, 1.682, 1.499, 1.225, 1.046, 1.068, 1.020m / s, A total of 14 fans are turned on, and the air volume of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com