A water-cooled crystallization process for steel ingot without riser

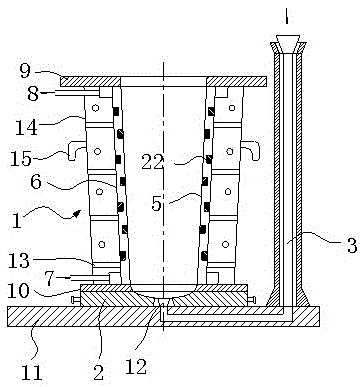

A steel ingot and water-cooling technology, which is applied in the field of water-cooled crystallization technology for steel ingots without risers, can solve the problems of low yield of steel products, inability to reach steel ingots, and generation of scrap steel, etc., and achieve high yield, good compactness of steel ingots, and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Type: high-quality carbon steel, steel type: 20, carbon content: 0.17-0.23%; tonnage: 8 tons;

[0034] After the front and rear parts of the water-cooled mold are fixed by bolts, the condensed water is fed into the water-cooled mold in advance, the temperature of the incoming water is less than 36°C, and the pressure of the incoming water is 0.5 MPa;

[0035] After the VD furnace is released, the temperature of the molten steel is 1585±5°C. After the temperature is controlled to 1570-1580°C, it is slowly poured into the mold of the water-cooled mold through the sprue, and the pouring time of the ingot body is 24-26min;

[0036] Continue to feed condensed water, keep warm for 10 minutes, and demould the steel ingot after condensation;

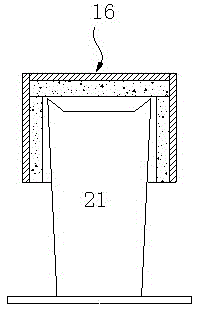

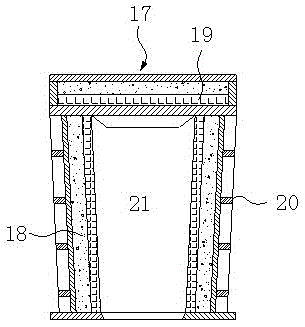

[0037] Put the heat preservation cover on the steel ingot after demoulding, and keep it warm for 4 hours (to ensure that the steel ingot is basically crystallized), and then remove the heat preservation cover.

[0038] Put the steel ingo...

Embodiment 2

[0042] Type: high-quality carbon steel, steel type: 65Mn, carbon content: 0.62-0.70%, tonnage: 11 tons;

[0043] After the front and rear parts of the water-cooled mold are fixed by bolts, the condensed water is fed into the water-cooled mold in advance, the temperature of the incoming water is less than 36°C, and the pressure of the incoming water is 0.5 MPa;

[0044] After the VD furnace is released, the temperature of the molten steel is 1550±5°C. After the temperature is controlled to 1535-1545°C, it is slowly injected into the mold of the water-cooled mold through the runner, and the pouring time of the ingot body is 15 minutes;

[0045] Continuously feed condensed water, keep warm for 12 minutes, and release the steel ingot from the mold after condensation;

[0046] Put the heat preservation cover on the steel ingot after demoulding, and remove the heat preservation cover after 5 hours of heat preservation.

[0047] Put the steel ingot with the insulation cover removed ...

Embodiment 3

[0051] Type: alloy steel, steel type: 5CrMnMo, carbon content: 0.50-0.60%, tonnage 18 tons;

[0052]After the front and rear parts of the water-cooled mold are fixed by bolts, the condensed water is fed into the water-cooled mold in advance, the temperature of the incoming water is less than 36°C, and the pressure of the incoming water is 0.5 MPa;

[0053] After the VD furnace is released, the temperature of the molten steel is 1555±5°C. After the temperature is controlled to 1540-1550°C, it is slowly poured into the mold of the water-cooled mold through the runner, and the pouring time of the ingot body is 18 minutes;

[0054] Continuously feed condensed water, keep warm for 20 minutes, and release the steel ingot from the mold after condensation;

[0055] Put the heat preservation cover on the steel ingot after demoulding, and remove the heat preservation cover after 6 hours of heat preservation.

[0056] Put the steel ingot with the insulation cover removed into the insula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com