Normalized acid resistant hot-rolled steel plate and preparation method thereof

A hot-rolled steel plate, acid-resistant technology, applied in the direction of temperature control, etc., can solve the problems of harmful HIC resistance, expensive Mo alloy, increased smelting cost, etc., to achieve the matching of excellent strength and toughness and sulfide stress corrosion resistance, avoid Significantly decrease and improve the effect of strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

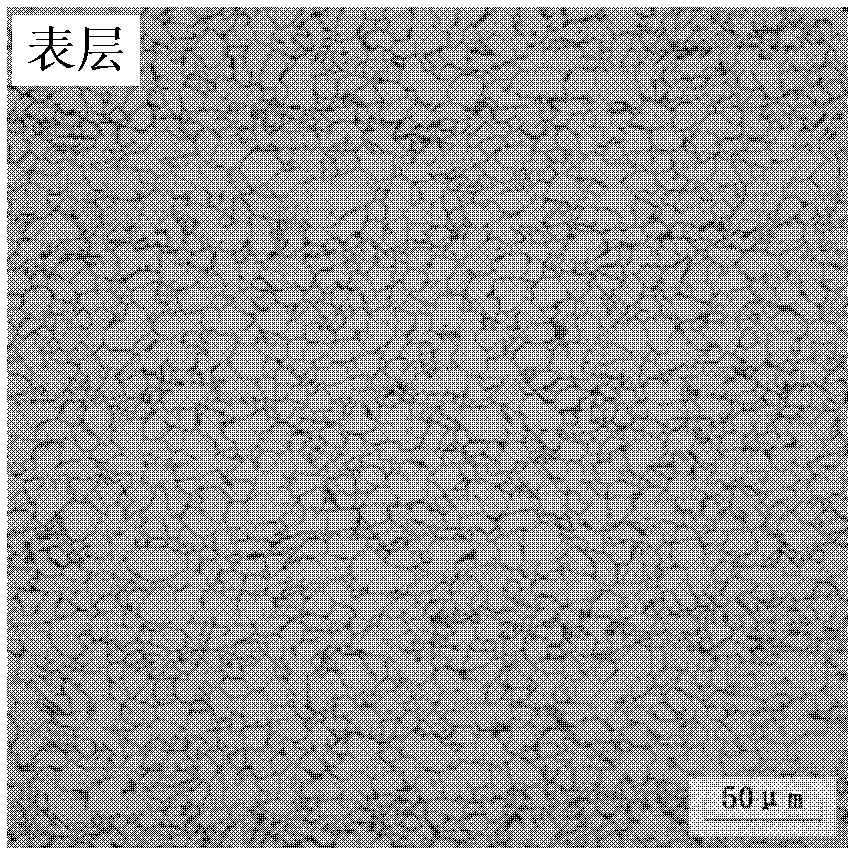

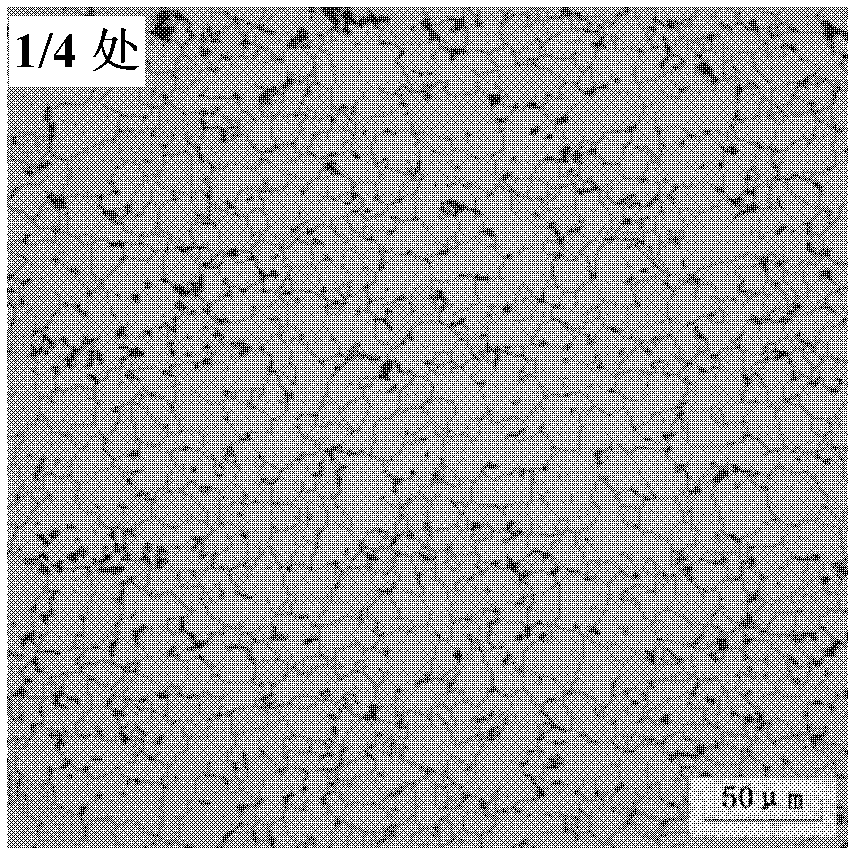

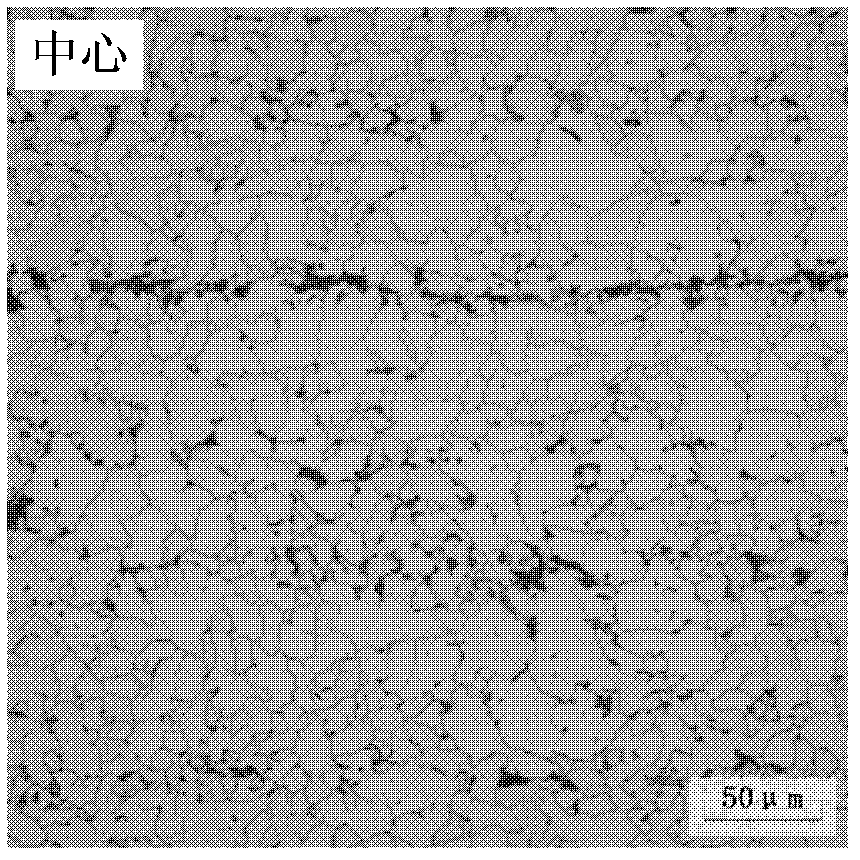

Image

Examples

Embodiment 1

[0033]The finishing temperature of LF furnace refining is 1644℃, and the treatment cycle of LF furnace is 45min. The casting machine tundish temperature is 1545°C, and the casting speed is 0.95m / min. The final rolling temperature of the steel billet in the first stage is 1010°C, the thickness of the intermediate billet to be warmed is 3.5 times the thickness of the finished product, the starting temperature of the second stage is 860°C, the final rolling temperature is in the range of 790°C, and it is air-cooled to room temperature after rolling. The steel plate is subjected to normalizing heat treatment at 880°C, and the holding time is 15 minutes.

Embodiment 2

[0035] The finishing temperature of LF furnace refining is 1646°C, and the treatment cycle of LF furnace is 50 minutes. The temperature of the tundish of the casting machine is 1540°C, and the casting speed is 1.00m / min. The final rolling temperature of the steel billet in the first stage is 1050°C, the thickness of the intermediate billet to be warmed is three times the thickness of the finished product, the starting temperature of the second stage is 890°C, the final rolling temperature is in the range of 800°C, and it is air-cooled to room temperature after rolling. The steel plate is subjected to normalizing heat treatment at 890°C, and the holding time is 10min.

Embodiment 3

[0037] The finishing temperature of LF furnace refining is 1640℃, and the treatment period of LF furnace is 30min. The temperature of the tundish of the casting machine is 1544°C, and the casting speed is 0.90m / min. The final rolling temperature of the steel billet in the first stage is 1020°C, the thickness of the intermediate billet to be warmed is 3.5 times the thickness of the finished product, the starting temperature of the second stage is 840°C, the final rolling temperature is in the range of 750°C, and it is air-cooled to room temperature after rolling. The steel plate is subjected to normalizing heat treatment at 900°C, and the holding time is 8 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com