Pipeline steel submerged arc welding wire for acid service environment

A service environment, pipeline steel technology, applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of easy softening area in the heat-affected zone, less alloy elements, etc., and increase the ability of acid corrosion resistance , good acid corrosion resistance, and the effect of improving the ability to resist hydrogen-induced cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

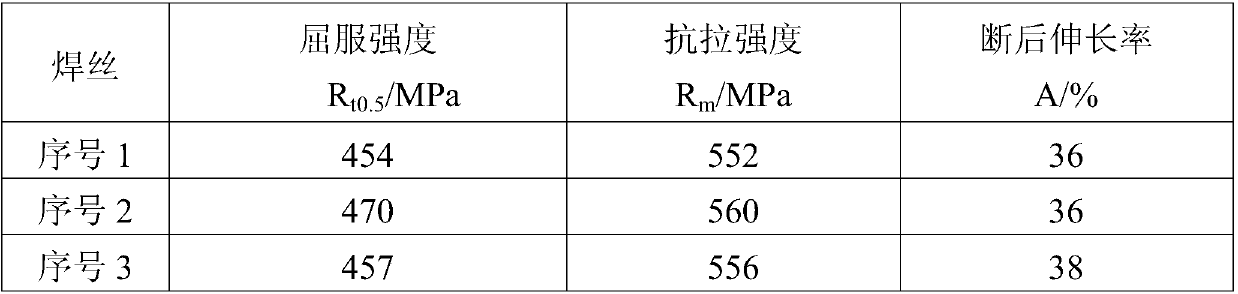

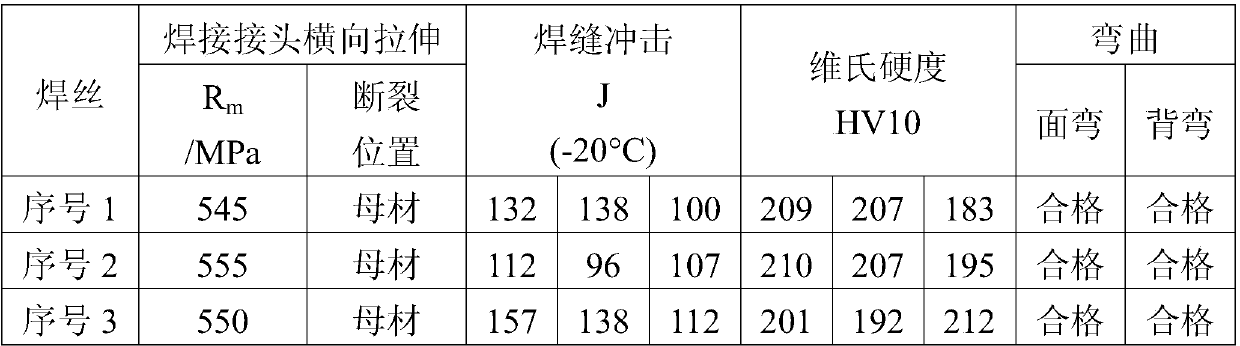

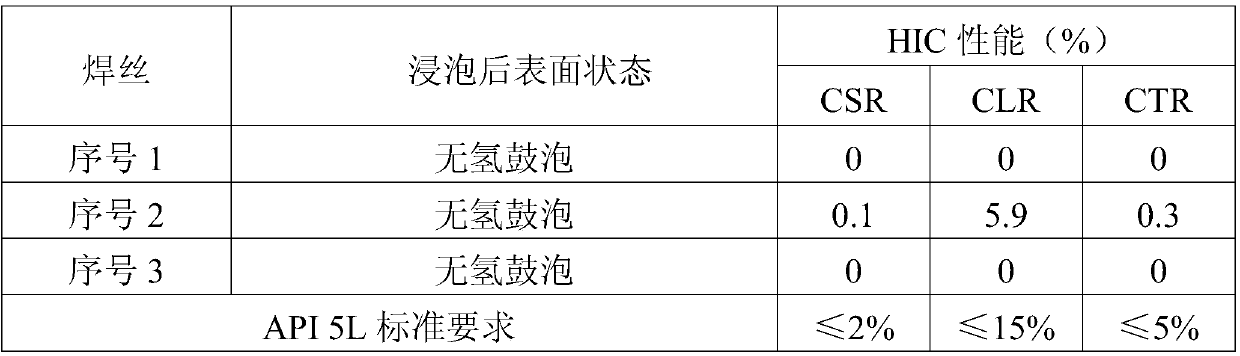

[0040] According to the scope of the chemical composition of the present invention, electric furnaces are used to smelt 3 furnaces of welding wire steel, and after smelting, a Φ4mm welding wire is made by drawing and plating copper.

[0041] The chemical composition of the fabricated welding wire and the calculated carbon equivalent and P cm The values are shown in Table 1.

[0042] Table 1 Chemical composition of test submerged arc welding wire

[0043] serial number

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com