Method for improving strip steel width control precision

A technology of width control and width, which is applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve the problems of inconsistency in the setting of width tolerance and width compensation value, limit the improvement of strip width control accuracy, etc., and achieve the improvement of strip steel The effect of width control accuracy and high pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

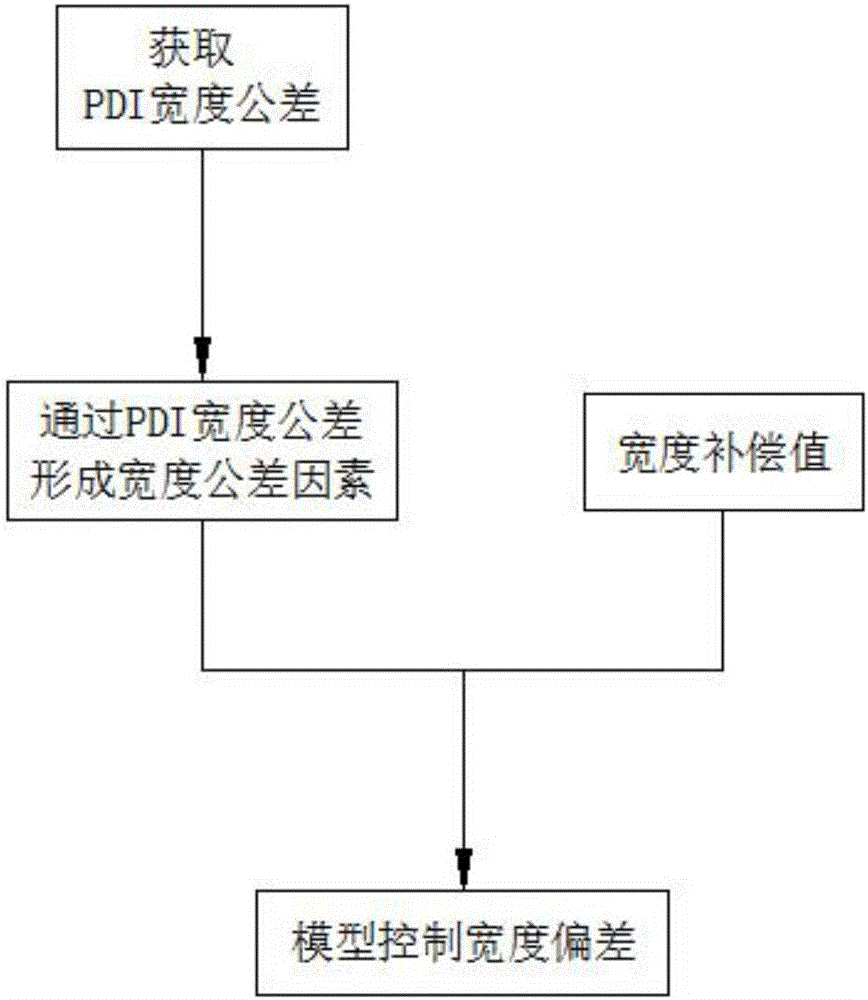

[0049] Get PDI width tolerance 0~10mm,

[0050] The width tolerance factor is formed by the PDI width tolerance, the middle value of the width tolerance factor=PDI width tolerance zone=(PDI width tolerance upper limit+PDI width tolerance lower limit)÷2=(0+10)÷2=5mm ,

[0051] The width tolerance factor combined with the width compensation value forms a model control width deviation, and the model control width deviation=5mm+width compensation value.

Embodiment 2

[0053] Get PDI width tolerance 0~15mm,

[0054] The width tolerance factor is formed by the PDI width tolerance, the middle value of the width tolerance factor=PDI width tolerance zone=(PDI width tolerance upper limit value+PDI width tolerance lower limit value)÷2=(0+15)÷2=7.5 mm,

[0055] The width tolerance factor combined with the width compensation value forms a model control width deviation, and the model control width deviation=7.5mm+width compensation value.

Embodiment 3

[0057] Get PDI width tolerance 0~20mm,

[0058] The width tolerance factor is formed by the PDI width tolerance, the middle value of the width tolerance factor=PDI width tolerance zone=(PDI width tolerance upper limit+PDI width tolerance lower limit value)÷2=(0+20)÷2=10mm ,

[0059] The width tolerance factor combined with the width compensation value forms a model control width deviation, and the model control width deviation=10mm+width compensation value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com