Preparation method of hot-rolled strip steel

A hot-rolled strip steel and strip steel technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems affecting the thickness and width hit rate of finished products, fluctuations in finished product thickness and width, unbalanced second flow, etc. , to improve the hit rate of thickness and width, solve the fluctuation of thickness and width, and optimize the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment Take the 1450mm strip steel hot rolling production line silicon steel model rolling control case of Jiangsu Shagang Group Co., Ltd. as an example, but the embodiment should not be construed as a limitation of the present invention.

[0015] overview

[0016] The slab used for rolling 1450mm strip steel will go through the processes including heating, rough rolling, finish rolling and coiling. The strip steel can be selected from grades W1300, W800 or W600 silicon steel. The conditions are as follows:

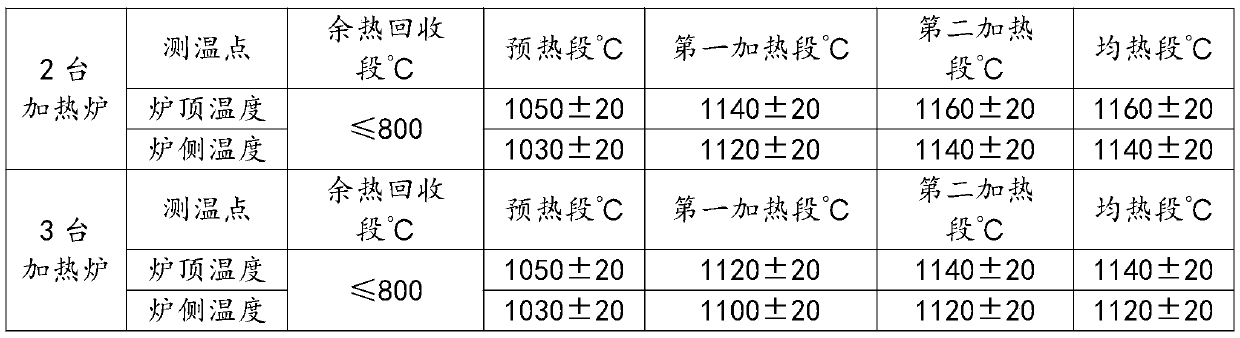

[0017] 1. Furnace temperature control (2 or 3 sets can be selected for operation)

[0018]

[0019] 2. Slab in furnace time: ≥150min

[0020] 3. Temperature control requirements for key rolling processes

[0021]

[0022] 4. The finishing control requirements

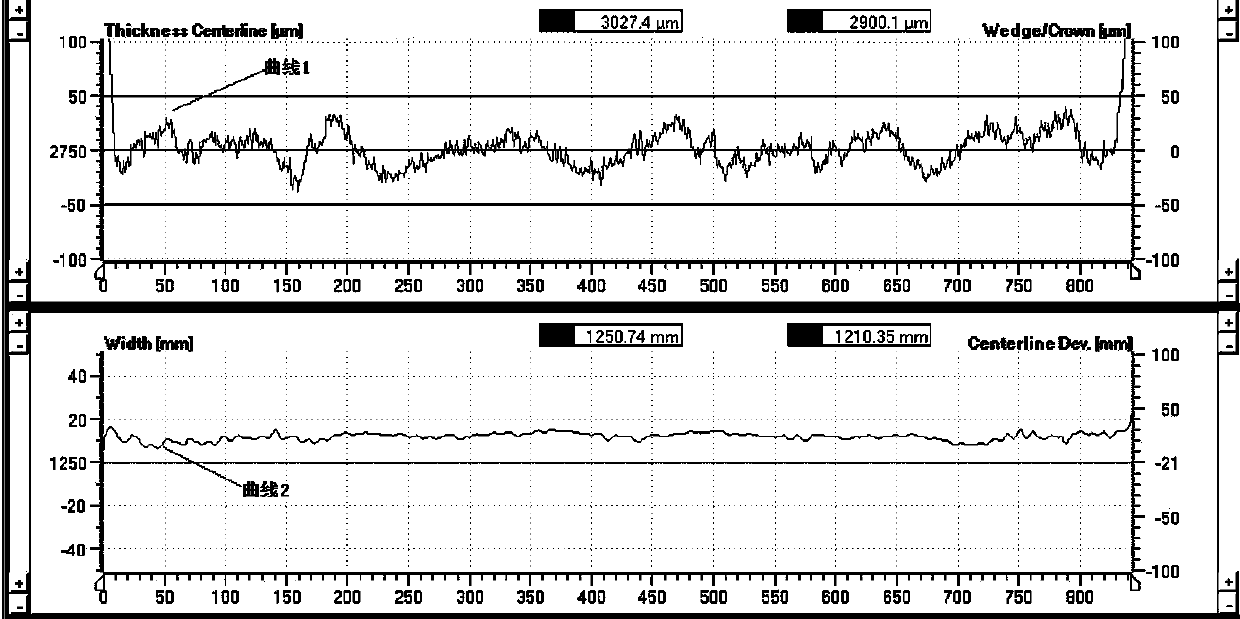

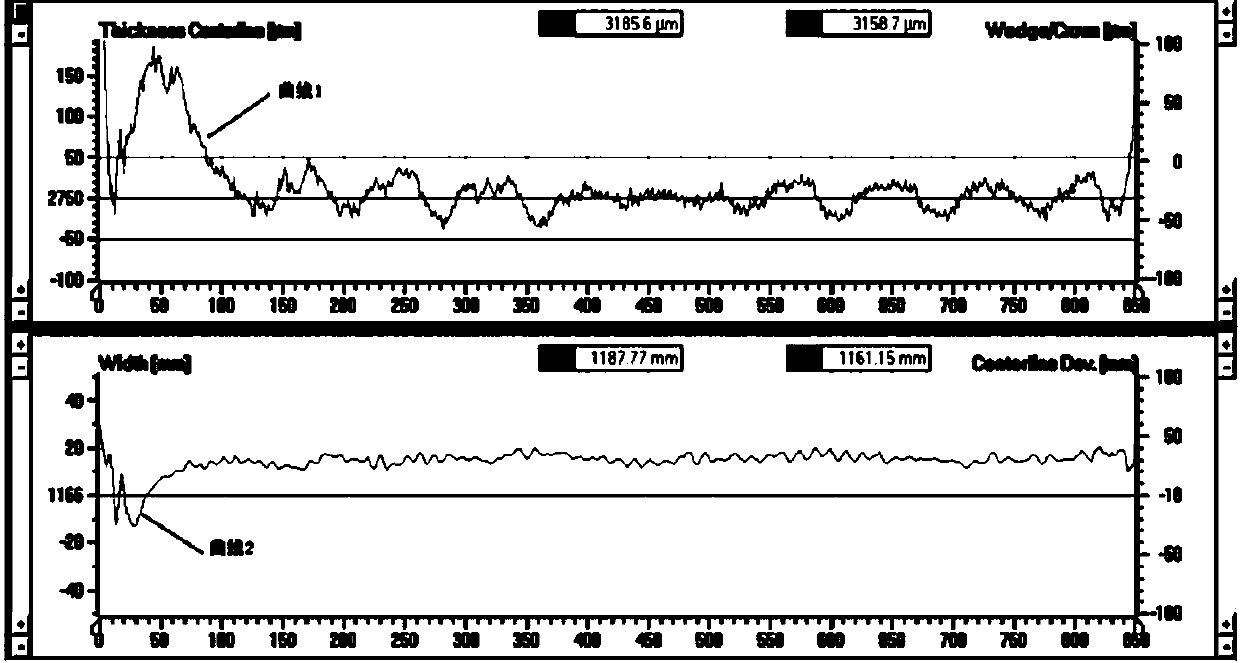

[0023] In the case of normal rolling production of 7 continuous rolling mills F1-F7 of the finishing rolling group, before the strip steel enters the finishing rolling mill, input the rolling p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com