a bracket

A technology of moving the frame and the top beam, which is applied in the direction of the mine roof support, mining equipment, earth-moving drilling and mining, etc., can solve the problems of the non-parallel roof beam and easy collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

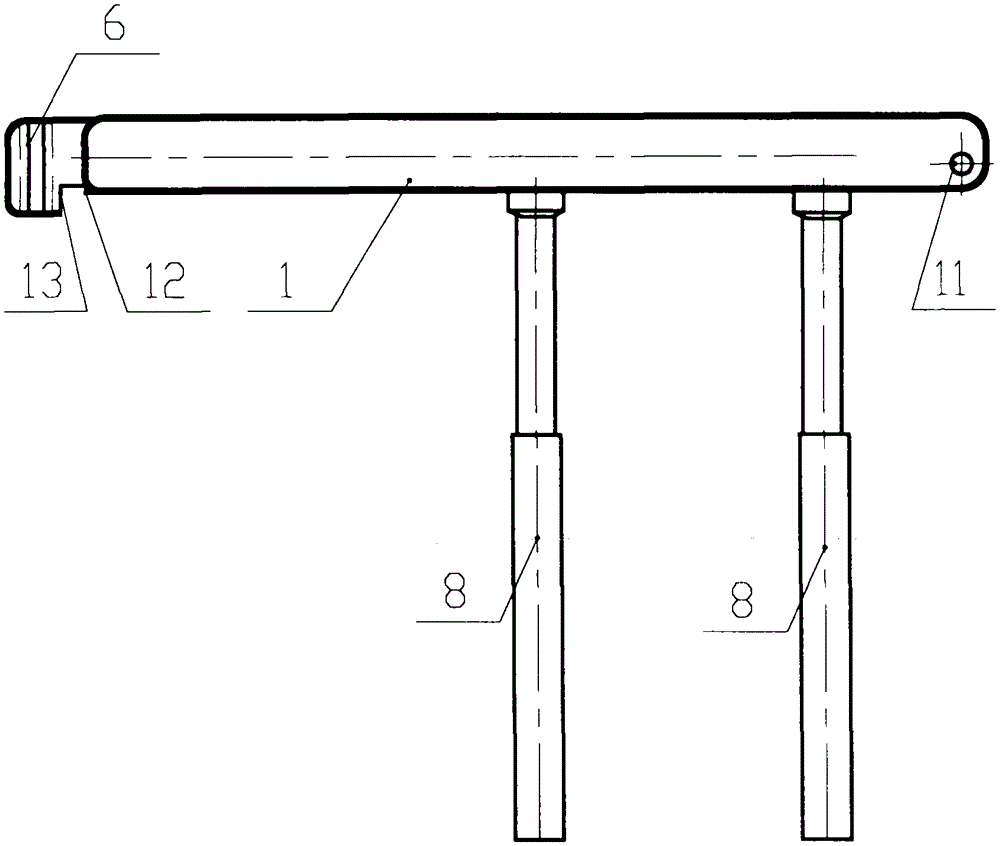

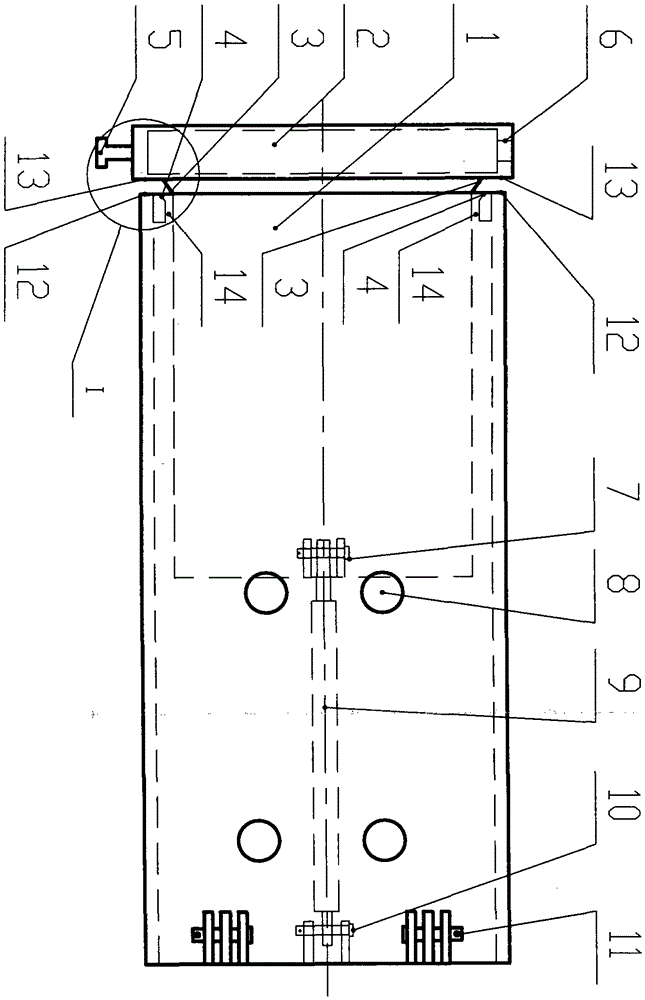

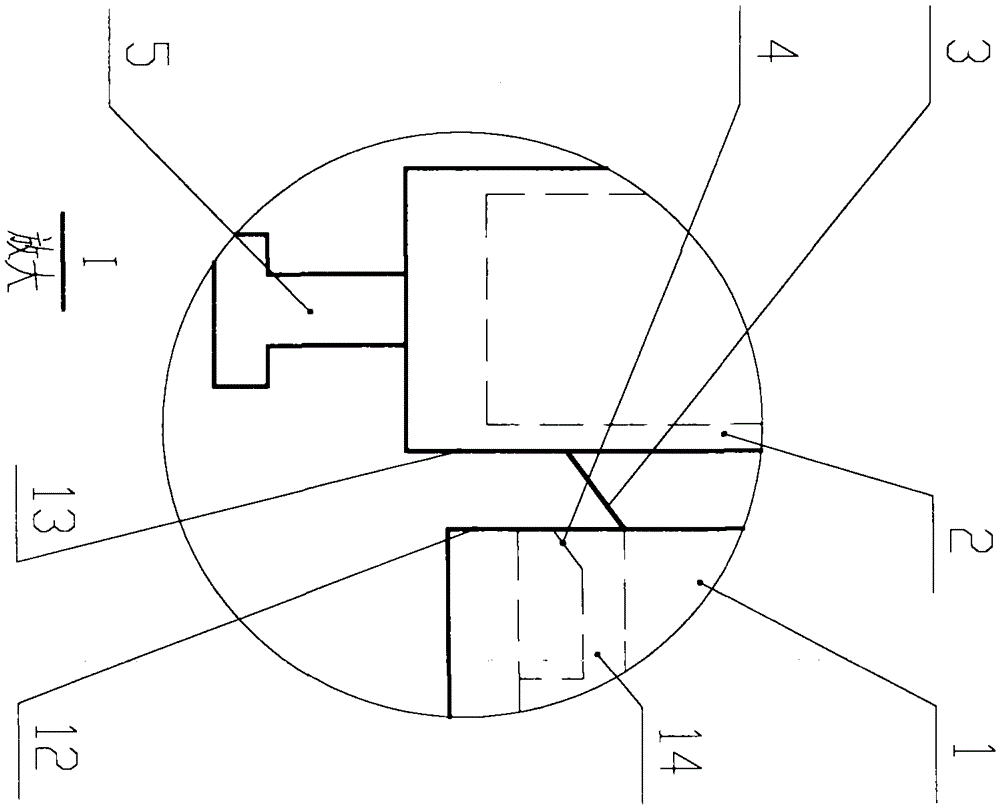

[0014] combine figure 1 , figure 2 , image 3 with Figure 4 , the first embodiment of the present invention, including a top beam 1, a front extension beam 2, a hydraulic prop 8, a right connector 5 located on the right side of the front end of the front extension beam 2, and a left connector 6 located on the left side of the front end of the front extension beam 2 , the moving surface 13 and the inclined plane 3 connected together with the front extension beam 2 . The projection 4 and the positioning surface 12 connected together with the top beam 1 are located in the gap 14 between the projection 4 and the side of the front extension beam 2, connected with the front extension beam 2 by the front pin 7 and connected with the top by the rear pin 10. The propulsion cylinder 9 connected with the beam 1 and the device 11 connected with the rejecting device. The moving surface 13 and the positioning surface 12 constitute an automatic centering device for the top beam when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com