Tension frame suitable for steel sheets with different lengths

A steel sheet and adaptation technology, applied in laser welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve the problems of cumbersome switching of tensioning frames, etc., and achieve the effect of simple and convenient use and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

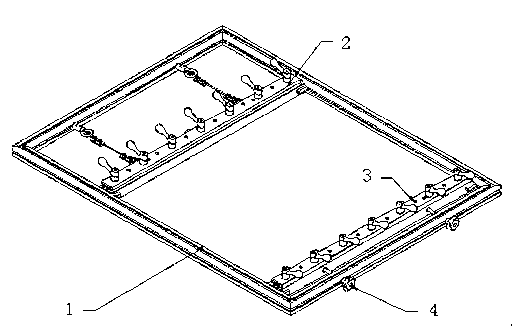

[0029] A tension frame adapted to steel sheets of different lengths, such as figure 2 , 3 As shown, it includes the outer frame, fixed beam, movable beam, constant load spring, fixed beam guide groove, fixed beam positioning mechanism, and driving screw; the two ends of the constant load spring are respectively connected to the fixed beam and the outer frame, and the outer frame has a scale , corresponding to the fixed beam positioning mechanism, the fixed beam positioning mechanism is located between the fixed beam and the constant load spring; the driving screw is located on the outer frame and connected with the movable beam.

[0030]

Embodiment 2

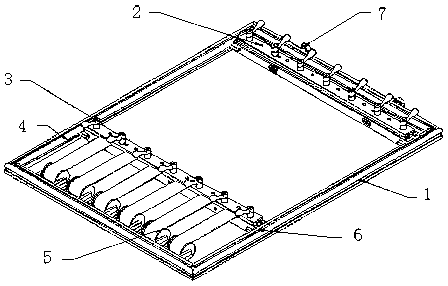

[0032] A tensioning frame adapted to steel sheets of different lengths, including an outer frame, a fixed beam, a movable beam, a constant load spring, a guide groove of the fixed beam, a positioning mechanism for the fixed beam, and a driving screw; the two ends of the constant load spring are respectively connected to the fixed beam And on the outer frame, the outer frame has a scale corresponding to the fixed beam positioning mechanism, the fixed beam positioning mechanism is located between the fixed beam and the constant load spring; the driving screw is located on the outer frame, and is connected with the movable beam.

[0033] In the above solution, the constant load spring is used to tension the fixed beam of the tension frame, which actually changes the significance of the existence of the movable beam and the fixed beam itself. The structure of the movable beam does not require major changes, only a standard needs to be added to locate the tensioned state of the stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com