Special carbon-vinegar slow-release biological fertilizer for tobaccos and preparation method thereof

A technology of biological fertilizer and slow-release granular fertilizer, which is applied in application, fertilization device, fertilizer mixture, etc., can solve the problems of not having abundant voids and high cost, and achieve the goal of reducing the occurrence of crop diseases and insect pests, promoting plant growth, and increasing plant growth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

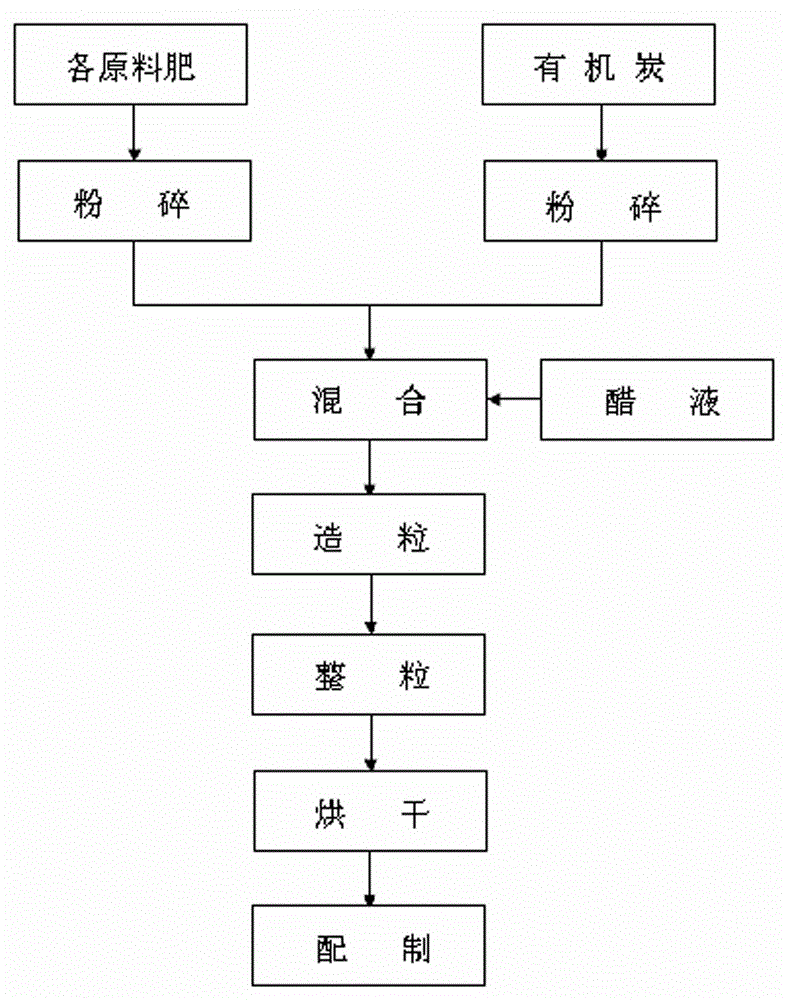

[0019] The preparation method of special charcoal vinegar slow-release bio-fertilizer for tobacco of the present invention comprises slow-release granule fertilizer preparation, nutrient analysis, preparation steps, specifically comprises:

[0020] A. Preparation of slow-release granular fertilizer: Pulverize each prepared raw material fertilizer and organic carbon respectively, mix each raw material according to the weight ratio of each raw material fertilizer and organic carbon 50~80:20~50, and then spray 50% of the weight of each raw material 13~98‰ of vinegar solution, stirred evenly, granulated, granulated, and dried to obtain various slow-release granular fertilizers;

[0021] B. Nutrient analysis: analyze soil nutrients and crop characteristics, and obtain analysis and inspection reports;

[0022] C. Preparation: According to the analysis and inspection reports of various soil nutrients and crop characteristics, the target tobacco-specific charcoal vinegar slow-release ...

Embodiment 1

[0035] Example 1——Preparation of slow-release granular fertilizer

[0036] 100Kg of urea, 100Kg of potassium nitrate, 100Kg of ammonium nitrate, 100Kg of diammonium phosphate, 100Kg of double superphosphate, 100Kg of potassium chloride, 100Kg of potassium sulfate, 10Kg of magnesium sulfate, 10Kg of zinc sulfate, 10Kg of ferrous sulfate, 10Kg of boric acid, Borax 10Kg, copper sulfate 10Kg, ammonium molybdate 10Kg and organic carbon 100 t are pulverized respectively through a 100-mesh sieve, and mixed according to each raw material fertilizer: organic carbon weight ratio 50:20 to obtain slow-release urea 140Kg and slow-release potassium nitrate 140Kg respectively , Slow-release ammonium nitrate phosphate 140Kg, slow-release diammonium phosphate 140Kg, slow-release double superphosphate 140Kg, slow-release potassium chloride 140Kg, slow-release potassium sulfate 140Kg, slow-release magnesium sulfate 14Kg, slow-release zinc sulfate 14Kg, slow-release Ferrous sulfate 14Kg, slow-rel...

Embodiment 2

[0037] Example 2——Preparation of slow-release granular fertilizer

[0038]100Kg of urea, 100Kg of potassium nitrate, 100Kg of ammonium nitrate, 100Kg of diammonium phosphate, 100Kg of double superphosphate, 100Kg of potassium chloride, 100Kg of potassium sulfate, 10Kg of magnesium sulfate, 10Kg of zinc sulfate, 10Kg of ferrous sulfate, 10Kg of boric acid, Borax 10Kg, copper sulfate 10Kg, ammonium molybdate 10Kg and organic carbon 100 t are pulverized respectively through a 100-mesh sieve, and mixed according to each raw material fertilizer: organic carbon weight ratio 80:50 to obtain slow-release urea 160 Kg, slow-release potassium nitrate 160Kg, slow-release ammonium nitrate phosphate 160Kg, slow-release diammonium phosphate 160Kg, slow-release double superphosphate 160Kg, slow-release potassium chloride 160Kg, slow-release potassium sulfate 160Kg, slow-release magnesium sulfate 16Kg, slow-release zinc sulfate 16Kg, slow-release Release ferrous sulfate 16Kg, slow-release bori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com