Over-the-wall forming mould of inner liner of refrigerator door

A technology for forming molds and refrigerators, which is applied in the field of forming molds for wall-mounted refrigerator door sleeves, can solve the problems of reducing the production efficiency of refrigerator door sleeves, cumbersome processing procedures, etc., and achieves the effects of simple structure, accelerated production efficiency, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

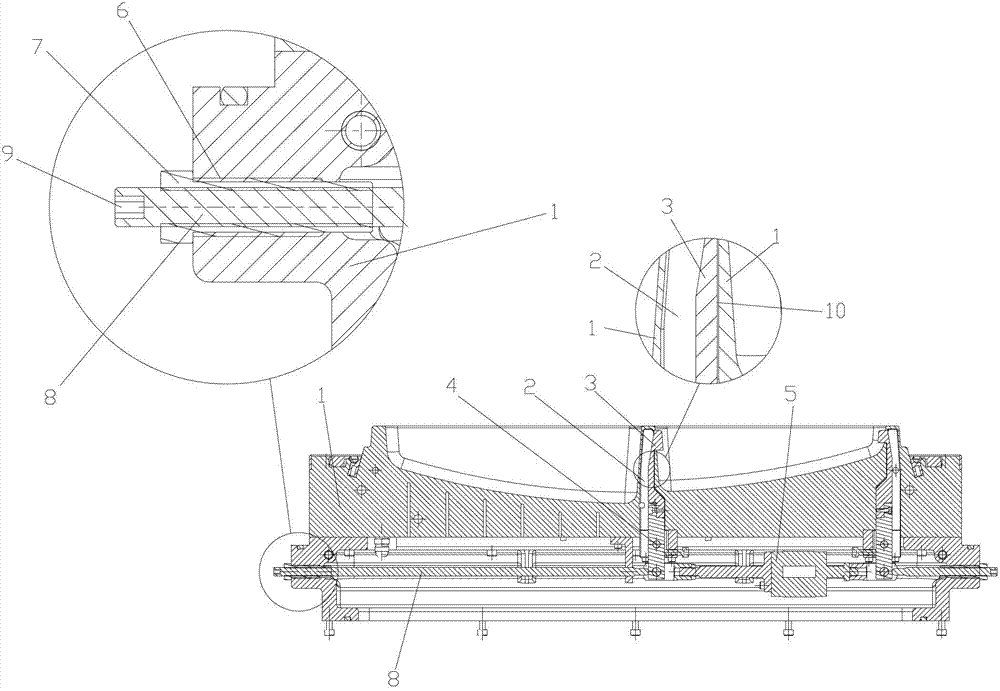

[0015] like figure 1 As shown, the refrigerator door liner wall-hanging forming mold provided in this embodiment includes a mold cavity 2 arranged in the refrigerator door liner plastic mold body 1, and the mold cavity 2 is provided with a vertically arranged The wall-hanging forming mold body 3, and the upper end of the wall-hanging forming mold body 3 stretches out of the cavity 2. The wall-hanging forming mold body 3 is hinged on the refrigerator door liner plastic-absorbing mold body 1 through a rotating shaft 4 and can be turned inside and outside (with reference to the upper end of the wall-hanging forming mold body).

[0016] Below the rotating shaft 4 is arranged an overturning mechanism that pushes the wall-hanging forming mold body 3 to turn outwards. The overturning mechanism can adopt various structural forms that those skilled in the art can think of. And in the present embodiment, the detailed structure of turnover mechanism is as follows: refer to figure 1 As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com