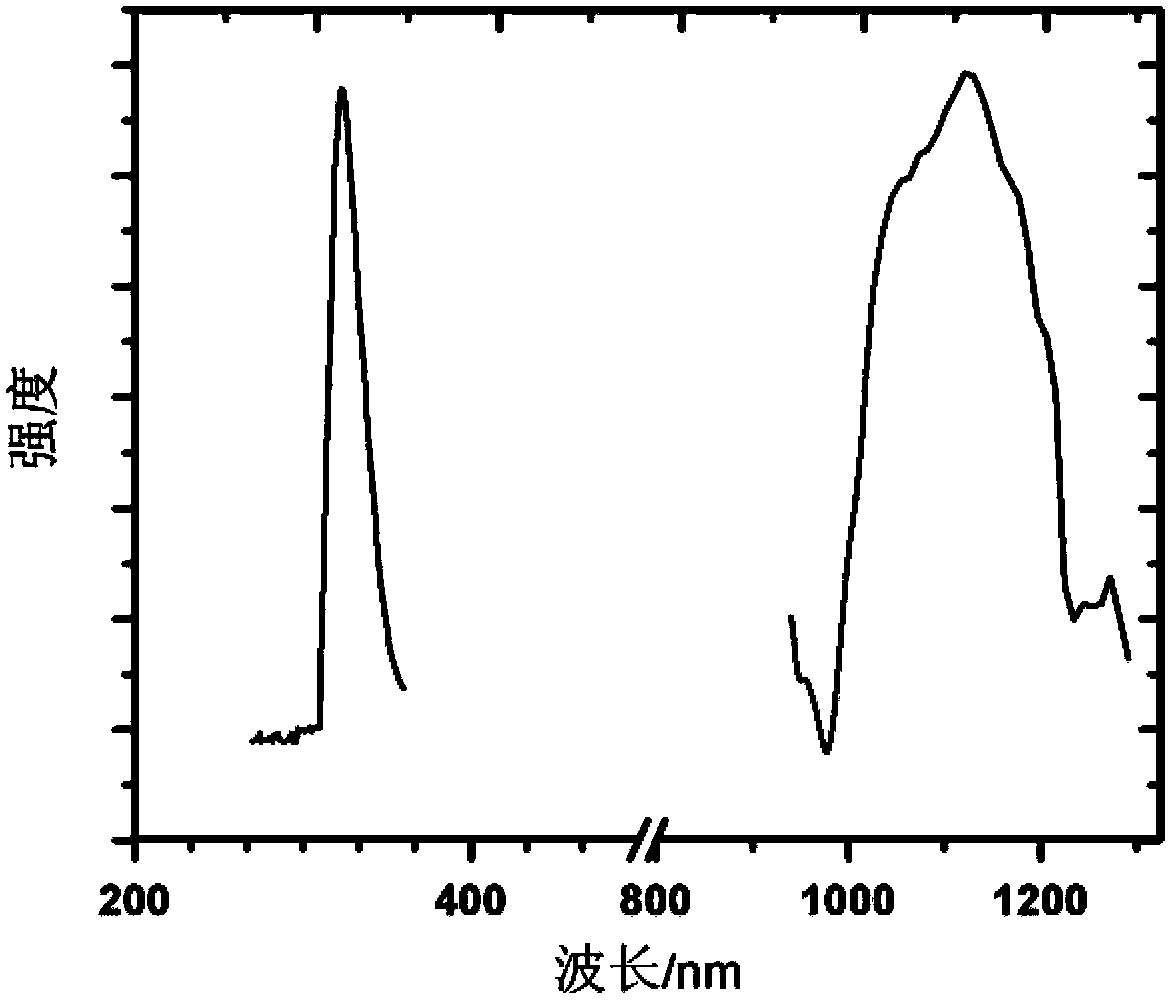

Cadmium sulfide-containing two-wavelength light absorption aqueous anti-counterfeiting ink additive preparation process

A technology of anti-counterfeiting ink and preparation process, which can be applied to inks, household utensils, applications, etc., and can solve the problem of low anti-counterfeiting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] 1) Put 4g of cadmium sulfide with a particle size of 80-200nm in 100g of deionized water, then add 0.30g of Tween 60, and then ultrasonically disperse the resulting mixed system at room temperature for 120min to obtain nano-cadmium sulfide solution;

[0125] 2) Mix 10g of polystyrenesulfonic acid-doped polyethylenedioxythiophene solution with a solid content of 1.3-1.7% and 10g of deionized water, then add 0.02g of sodium dodecylsulfonate, and then Use ultrasonic dispersion at 20°C for 80 minutes to obtain solution A;

[0126] 3) Mix the nano-cadmium sulfide solution and solution A at a mass ratio of 1:1 to obtain a mixed solution B; then heat the mixed solution B to 40°C, and then add ethylene glycol and particles to the mixed solution B under high-speed stirring diameter is 200-1000nm montmorillonite, reacted for 60 minutes, and finally obtained a dual-wavelength light-absorbing anti-counterfeiting ink additive containing cadmium sulfide; wherein, the added ethylene ...

Embodiment 2

[0128] 1) Put 4g of cadmium sulfide with a particle size of 80-200nm in 100g of deionized water, then add 0.30g of polyoxyethylene anhydrous xylitol monostearate and glycerol monopalmitate, and then use it at room temperature Ultrasonic cleaner ultrasonically disperses the obtained mixed system for 120 minutes to obtain nano-cadmium sulfide solution;

[0129] 2) Mix 10g of polystyrenesulfonic acid-doped polyethylenedioxythiophene solution with a solid content of 1.3-1.7% and 10g of deionized water, then add 0.02g of sodium dodecylsulfonate, and then Solution A was obtained by ultrasonic dispersion at 20°C for 60 minutes;

[0130] 3) Mix the nano-cadmium sulfide solution and solution A at a mass ratio of 1:1 to obtain a mixed solution B; then heat the mixed solution B to 40°C, and then add ethylene glycol and particles to the mixed solution B under high-speed stirring diameter is 200-1000nm montmorillonite, reacted for 60 minutes, and finally obtained a dual-wavelength light-a...

Embodiment 3

[0132] 1) Put 4g of cadmium sulfide with a particle size of 80-200nm in 100g of deionized water, then add 0.30g of lactic acid glycerol monofatty acid ester and lactic acid glyceryl diglyceride, and use ultrasonic waves at room temperature to shake the obtained mixed system Ultrasonic dispersion for 120 minutes to obtain nano-cadmium sulfide solution;

[0133] 2) Mix 10g of polystyrenesulfonic acid-doped polyethylenedioxythiophene solution with a solid content of 1.3-1.7% and 10g of deionized water, add 0.02g of sodium dodecylsulfonate, and then Solution A was obtained by ultrasonic dispersion at 20°C for 40 minutes;

[0134]3) Mix the nano-cadmium sulfide solution and solution A at a mass ratio of 1:1 to obtain a mixed solution B; then heat the mixed solution B to 40°C, and then add ethylene glycol and particles to the mixed solution B under high-speed stirring diameter is 200-1000nm montmorillonite, reacted for 60 minutes, and finally obtained a dual-wavelength light-absorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com