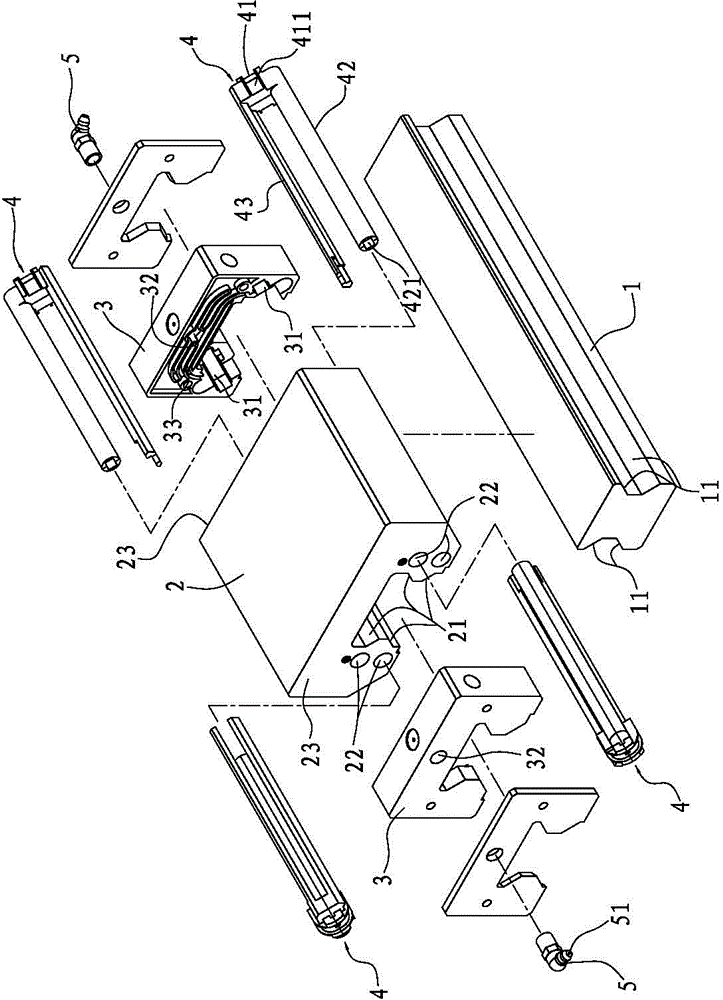

Linear slides with lubricating oil passages

A technology of linear slide rails and lubricating oil passages, applied in the direction of linear motion bearings, bearings, bearing components, etc., can solve problems such as inability to determine sufficient lubricating oil supply, insufficient lubricating oil supply, and insufficient lubricating oil filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

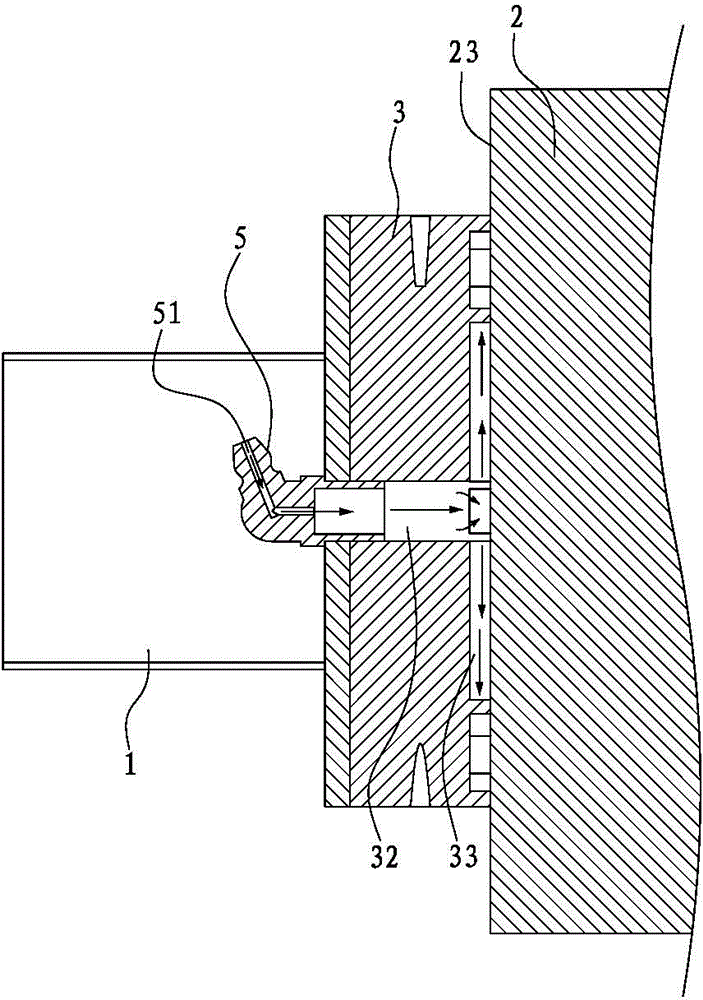

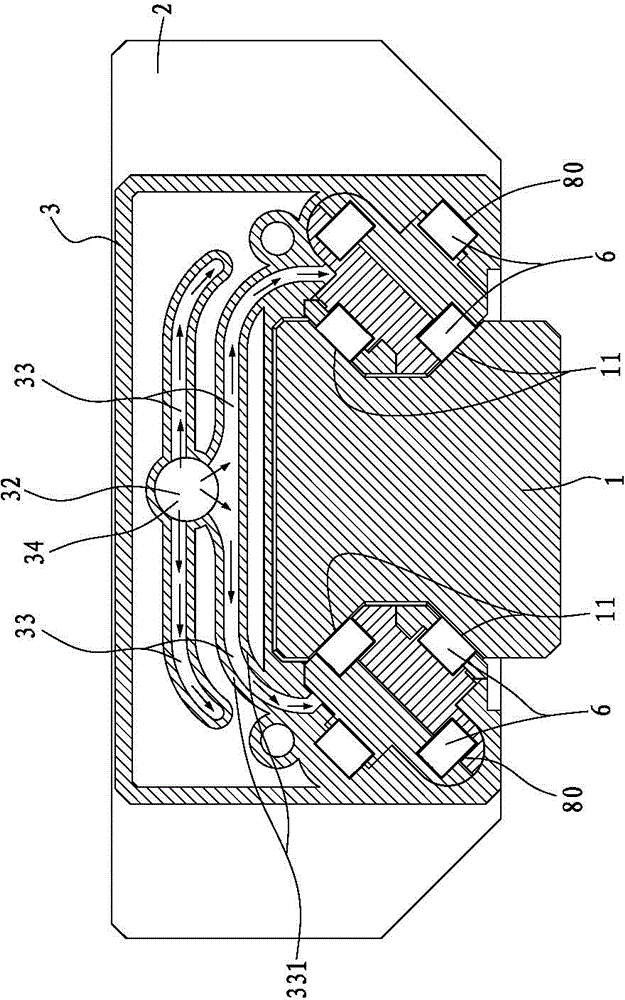

[0057] see Figure 6 and Figure 7 In the present invention, the normal direction of one end of the oil injection passage 32 is closed by the design of the pressure resistance plate 34, so when lubricating oil is injected into the oil injection passage, the lubricating oil will first impact the impact surface 341 of the pressure resistance plate 34 and then Then turn to flow into each of the oil passages 33 respectively, because the pressure resistance plate 34 has absorbed the pressure of the lubricating oil injection, so the pressure of the lubricating oil entering the oil passage 33 has become smaller, and the lubricating oil will not flow from the end cover 3 to the end surface. 23 seeps out, so the present invention prevents lubricating oil from leaking out during the injection process, and also ensures that the lubrication of the linear slide rail is sufficient to prolong its service life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com