A post-plating treatment device

A post-processing device and processing tank technology, applied in the field of electroplating post-processing devices, can solve the problems of harmful electroplating working liquid, great risk to the health of production personnel, low production efficiency, etc., so as to speed up production automation, reduce risks, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

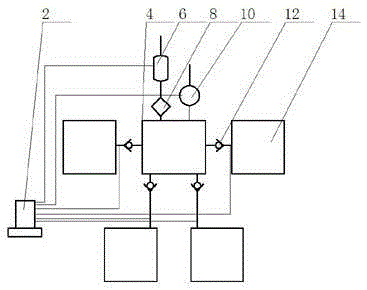

[0014] like figure 1 As shown, a kind of post-plating treatment device of the present invention comprises treatment tank 4, and several treatment liquid tanks 14 that communicate with treatment tank 4 respectively and accommodate different treatment liquids, each treatment liquid tank 14 is connected with treatment tank 4 The one-way valve 12 is also connected to the drain pump 10 on the treatment tank 4 . The workpiece after electroplating is placed in the treatment tank 4, and the one-way valve 12 is opened sequentially according to the post-plating treatment process sequence, so that the treatment liquid required for this process flows into the treatment tank 4 from the treatment liquid tank 14, and the workpiece is processed. After finishing a treatment procedure, close the one-way valve 12, and open the drain pump 10, drain the treatment liquid in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com