Spiral bridge support

A helical, bearing technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as uneven settlement of seismic anti-falling beams, etc., achieve good practical value and economic benefits, good earthquake-resistant anti-falling beams, prevent falling The effect of beam failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is a further description of the technical content of the patent of the present invention, but it is not a limitation to the essential content of the patent of the present invention.

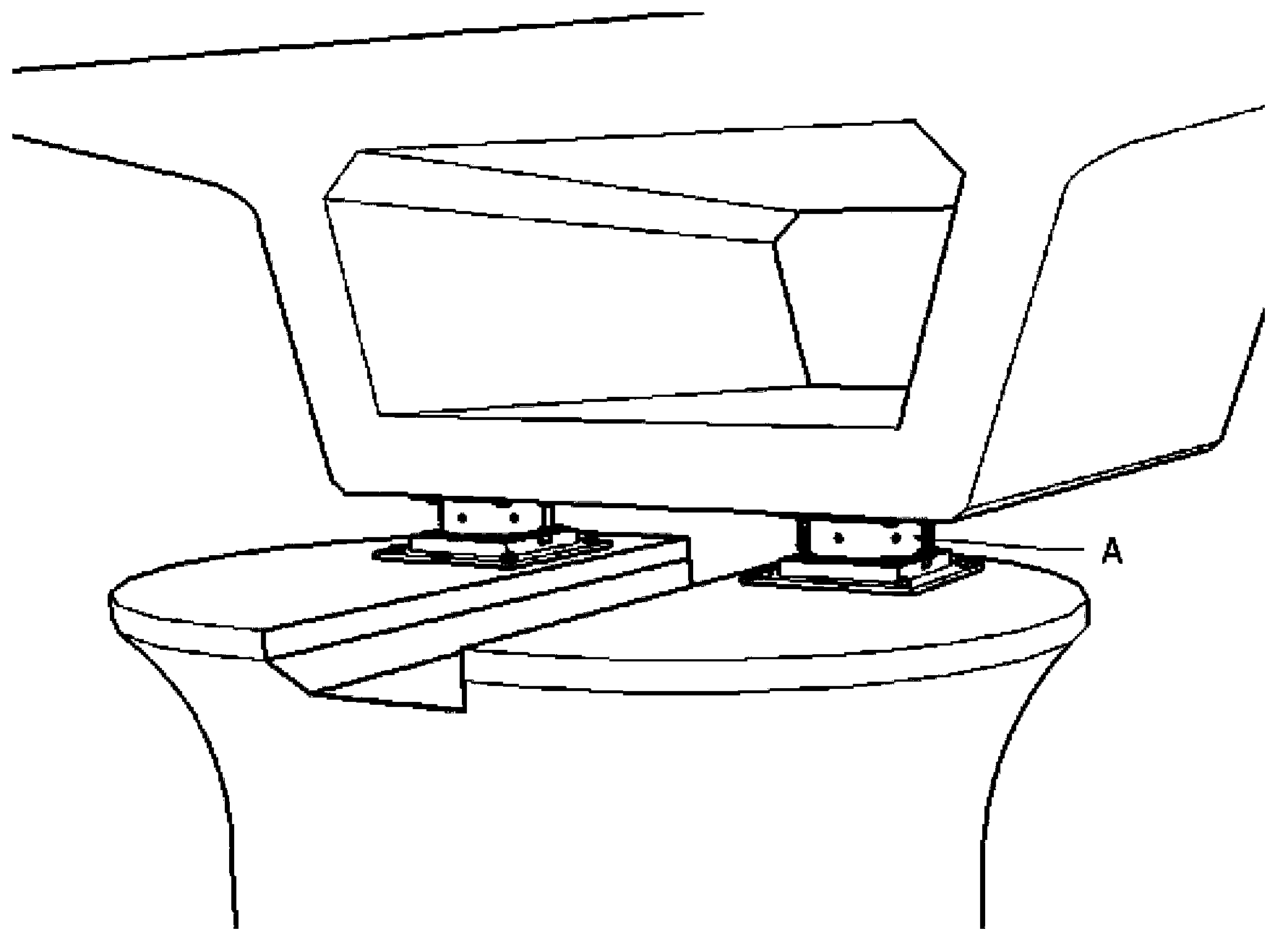

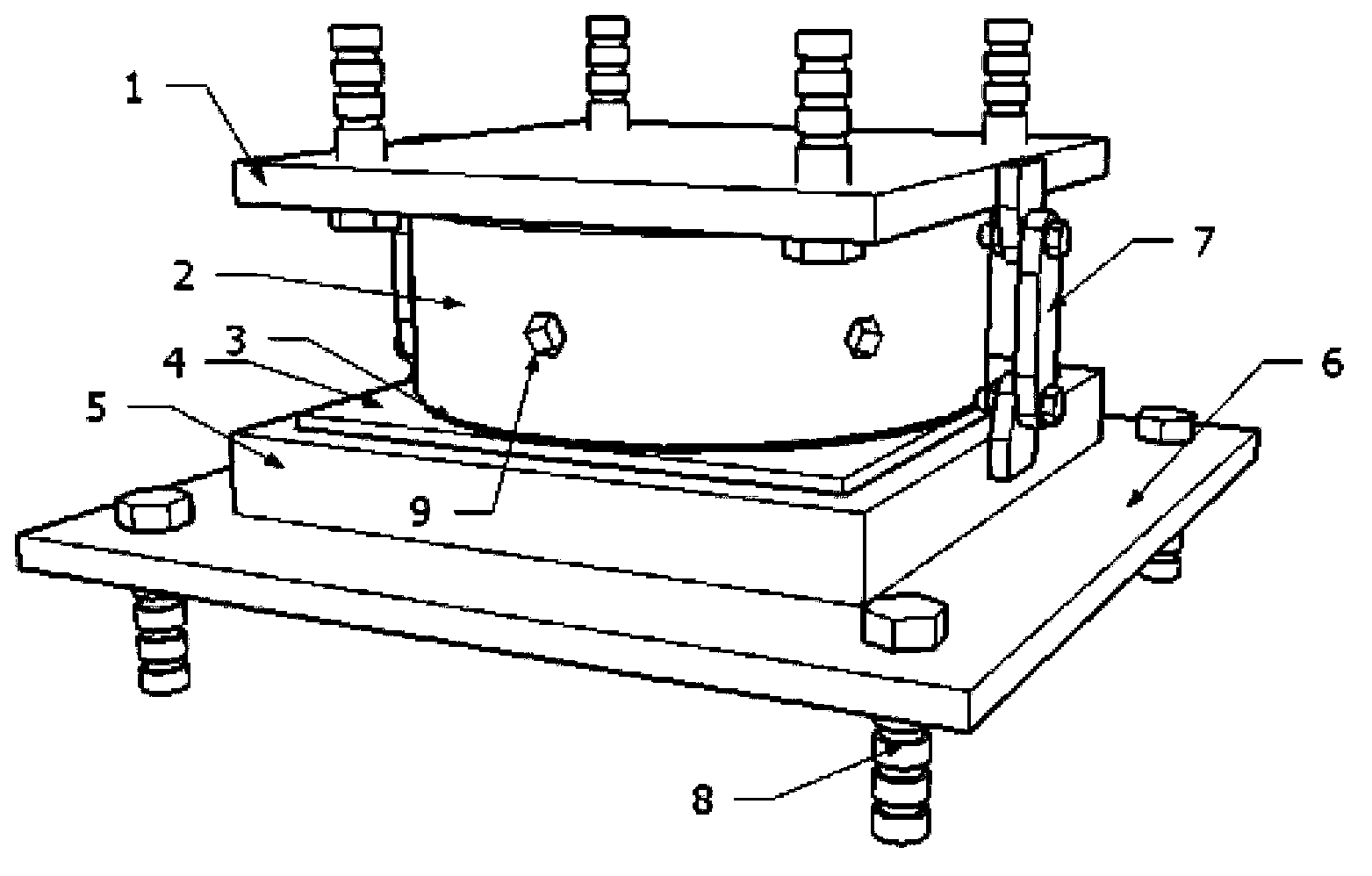

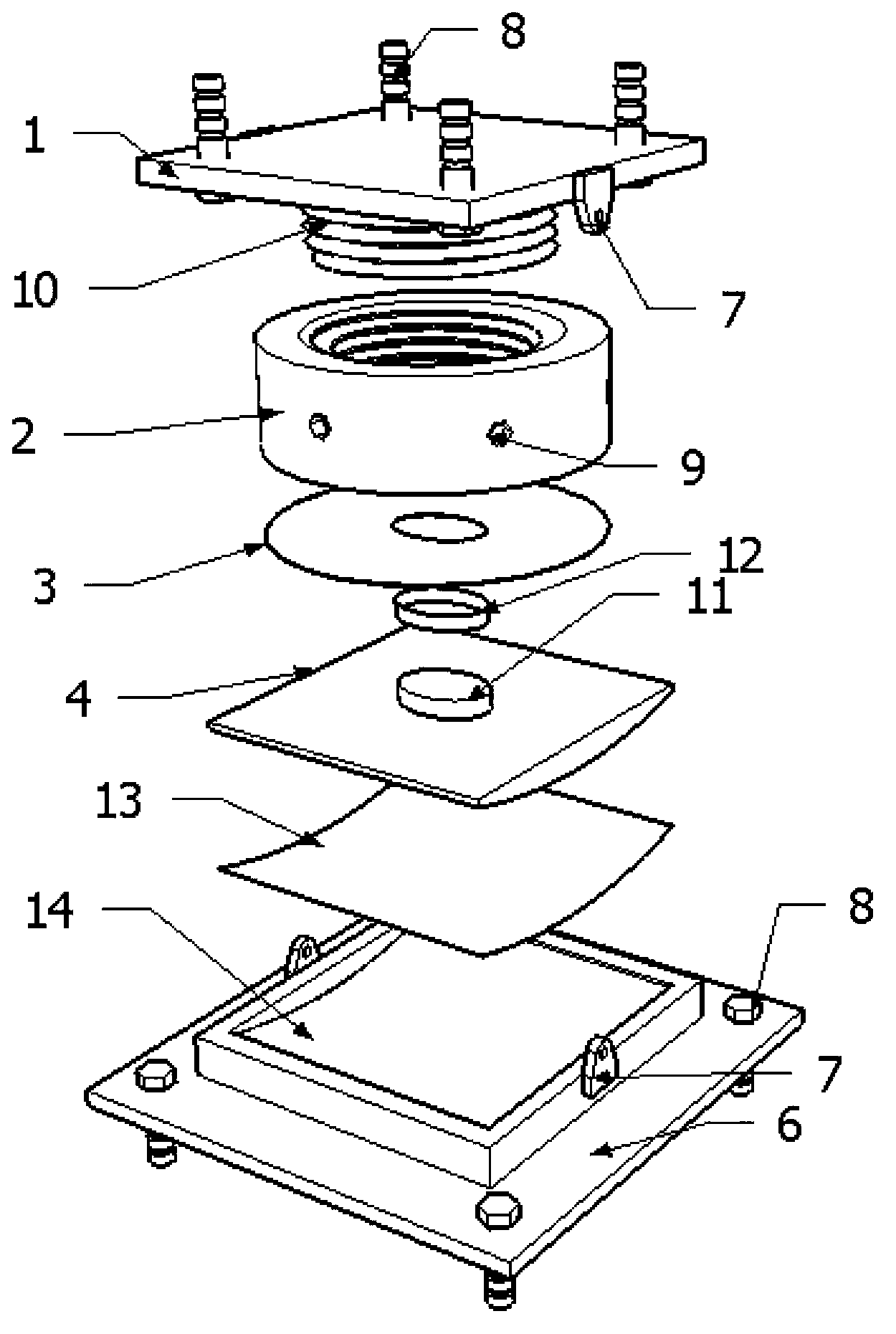

[0038] figure 1 It is the overall schematic diagram of the liftable spiral bearing of the bridge anti-drop beam; figure 2 for figure 1 Schematic diagram of the structure of the liftable spiral support A; image 3 for figure 2 Schematic diagram of the detailed structure of the assembly of the middle liftable spiral support member; Figure 4 for image 3 Schematic diagram of the overall structure of the middle and upper support plate and the screw-type support; Figure 5 for image 3 Schematic diagram of the structure of the medium nut type support; Figure 6 for image 3 Schematic diagram of the bottom plane structure of the medium nut type support; Figure 7 for image 3Three-dimensional view and top plan view of the center column panel; Figure 8 for image 3 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com