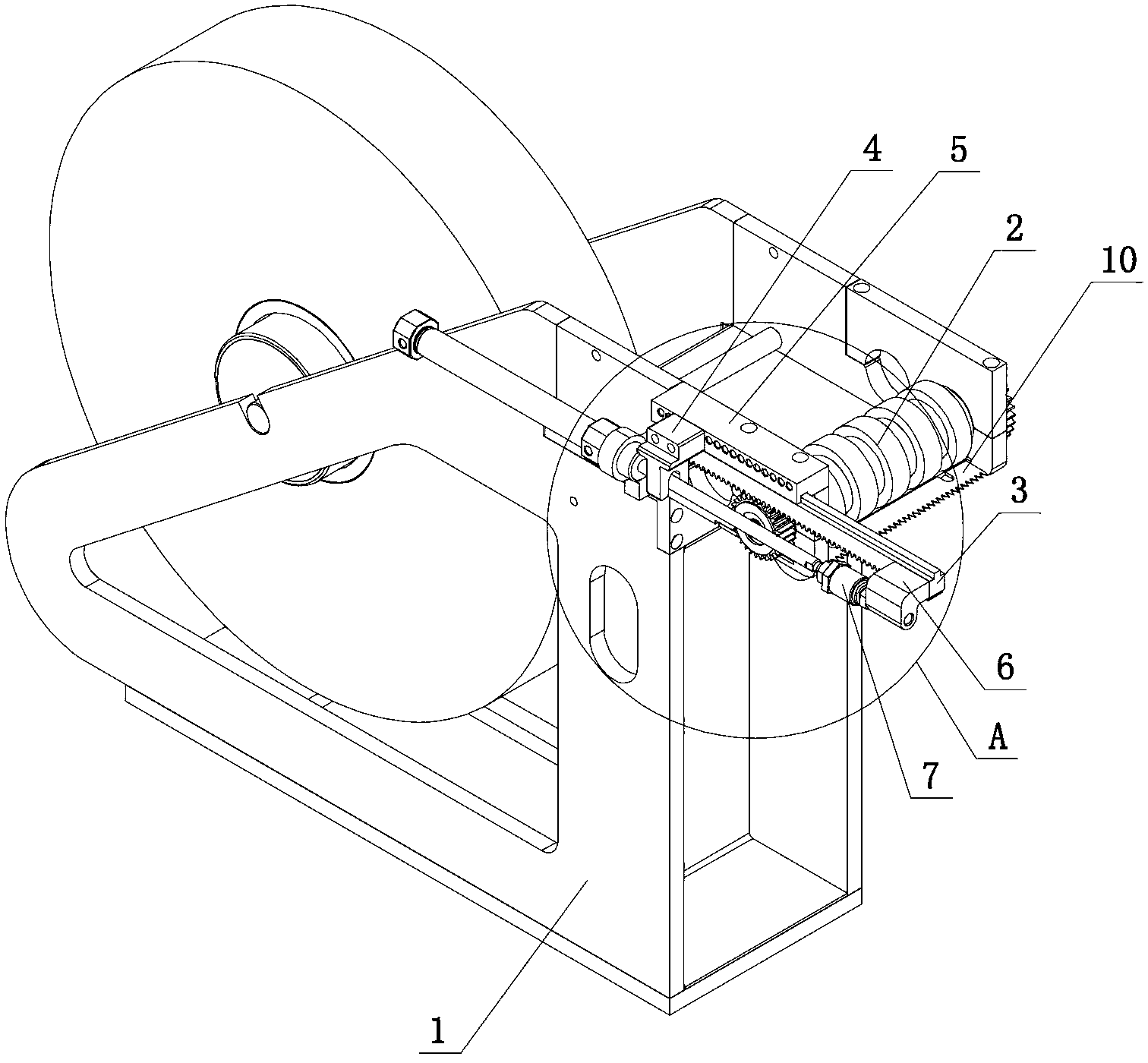

Film cutting machine

A film cutting machine and film ejecting technology, which is applied in the directions of sending objects, thin material processing, transportation and packaging, etc., can solve the problems of inability to improve the production efficiency of enterprises, low degree of automation, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

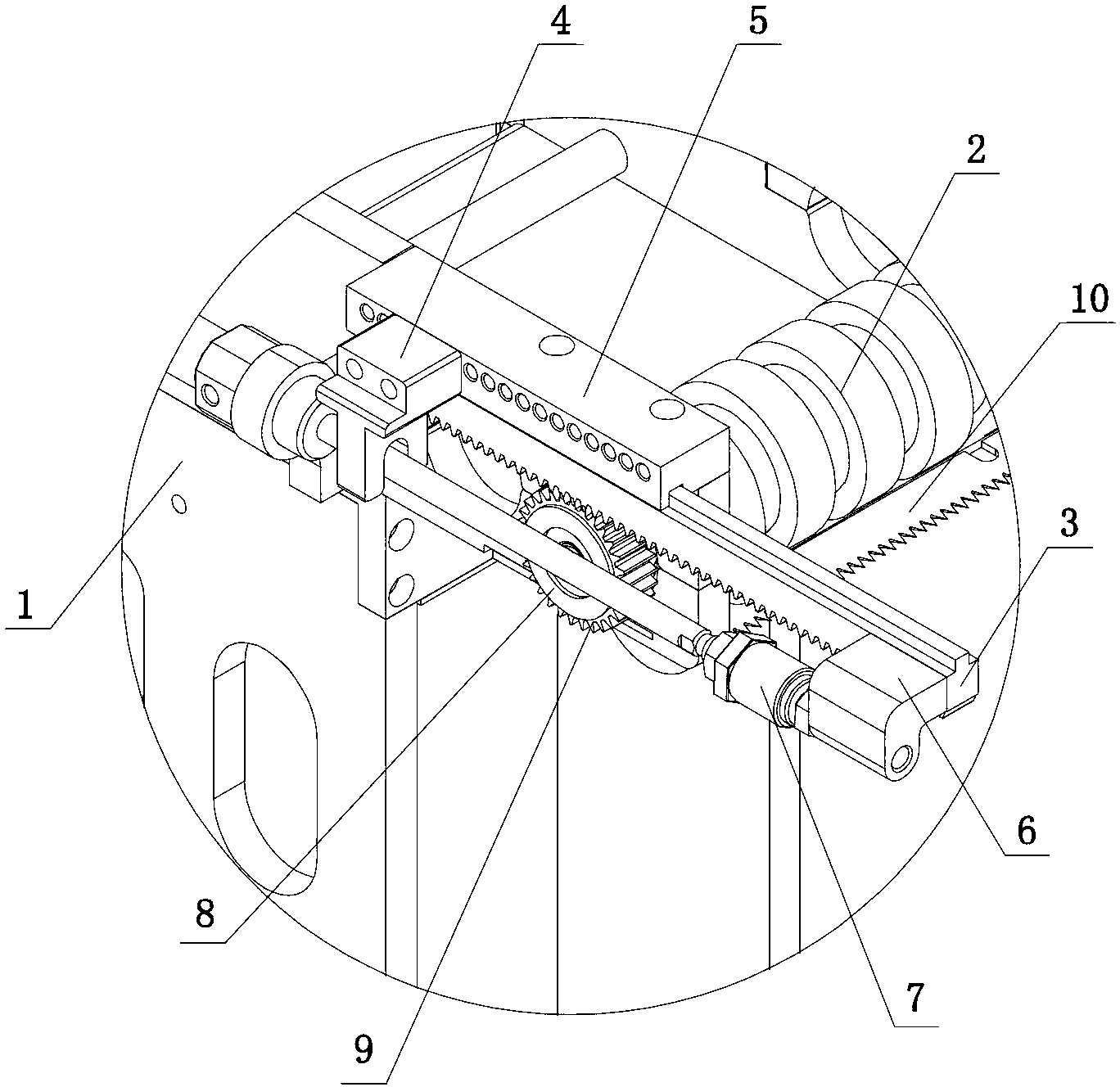

[0022] The driving device adopts an air cylinder or a hydraulic cylinder, the end of the piston rod of the air cylinder or hydraulic cylinder is connected to the rack 3, and a connecting device is provided at the joint, and the connecting device is composed of a floating joint 7 and a rack connecting block 6. , the floating joint 7 is connected to the end of the piston rod, the rack connection block 6 is fixed on the rack 3, and finally the floating joint 7 and the rack connection block 6 are fixed, so that the rack 3 is located in the air cylinder or hydraulic cylinder On one side, the rack 3 does not need to be fixed at the end of the piston rod, which saves space to a certain extent and makes the structure of the whole device more compact.

Embodiment approach 2

[0024] The driving device adopts a motor, and the output end of the motor is provided with a driving gear, and the driving gear is meshed with the rack 3. During specific implementation, the motor is installed on the support 1 on one side of the one-way bearing 8, and its output end is on the After the driving gear is installed, the driving gear and the gear 9 on the one-way bearing 8 are on the same horizontal plane, and then the rack 3 is installed on the upper part of the driving gear and the gear 9 on the one-way bearing 8, and the driving gear is driven by the motor to reciprocate running, thereby driving the rack 3 to reciprocate, and finally driving the film feeding roller 2 to run.

[0025] The specific embodiment of the drive device mentioned above, as a further improvement, a rack mounting seat 5 is provided above the rack 3, one side of the rack mounting seat 5 is fixed on the bracket 1, and a limit slot, and then set a raised portion on the top of the rack 3 that m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com