Support structure and camera module provided with same

A bracket structure and camera module technology, applied in image communication, camera body, color TV components and other directions, can solve the problems of poor imaging effect of camera module, etc., achieve good imaging effect, ensure filterability, The effect of increasing the space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The support structure and the camera module with the support structure will be described in detail below in conjunction with specific embodiments and drawings to make it more clear. However, the technical solutions of the bracket structure and the camera module with the bracket structure can be implemented in many different forms, and are not limited to the embodiments described herein. On the contrary, the purpose of providing these embodiments is to make the disclosure of the bracket structure and the camera module with the bracket structure more thorough and comprehensive.

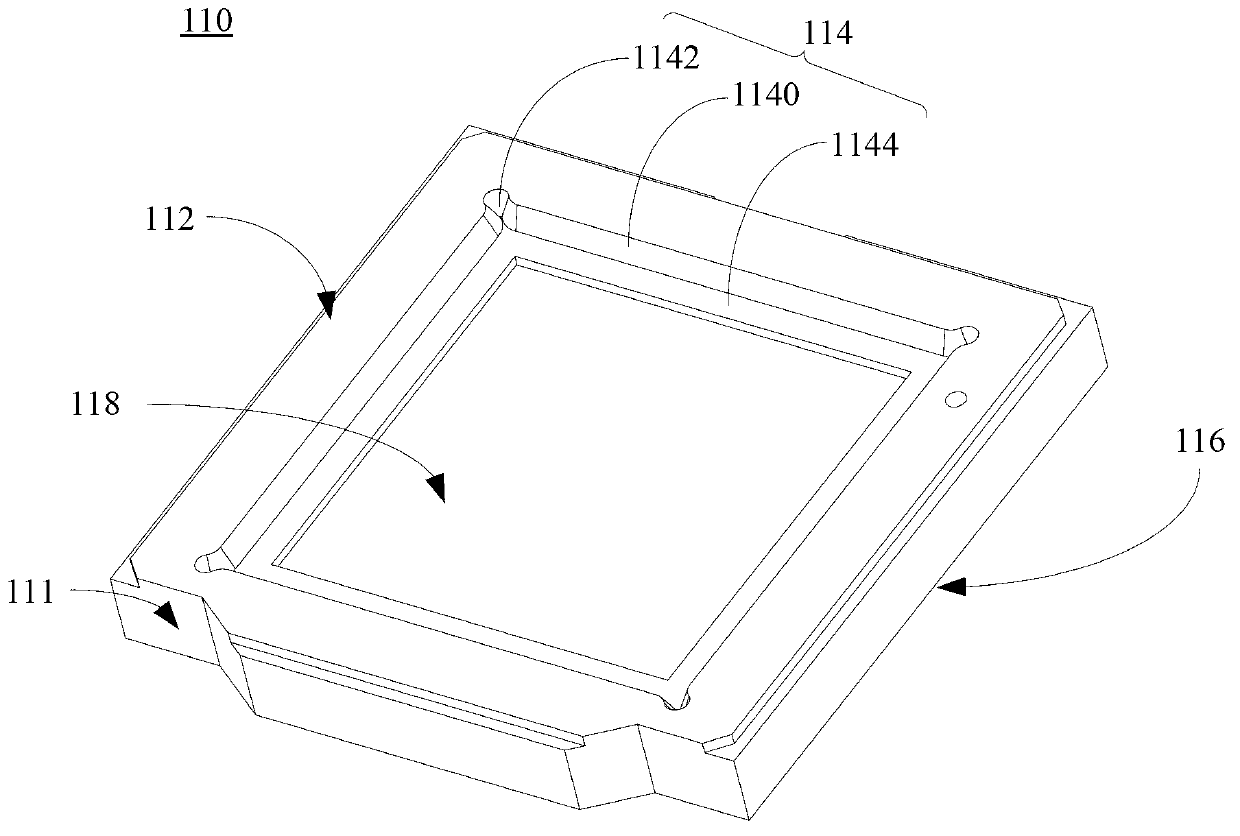

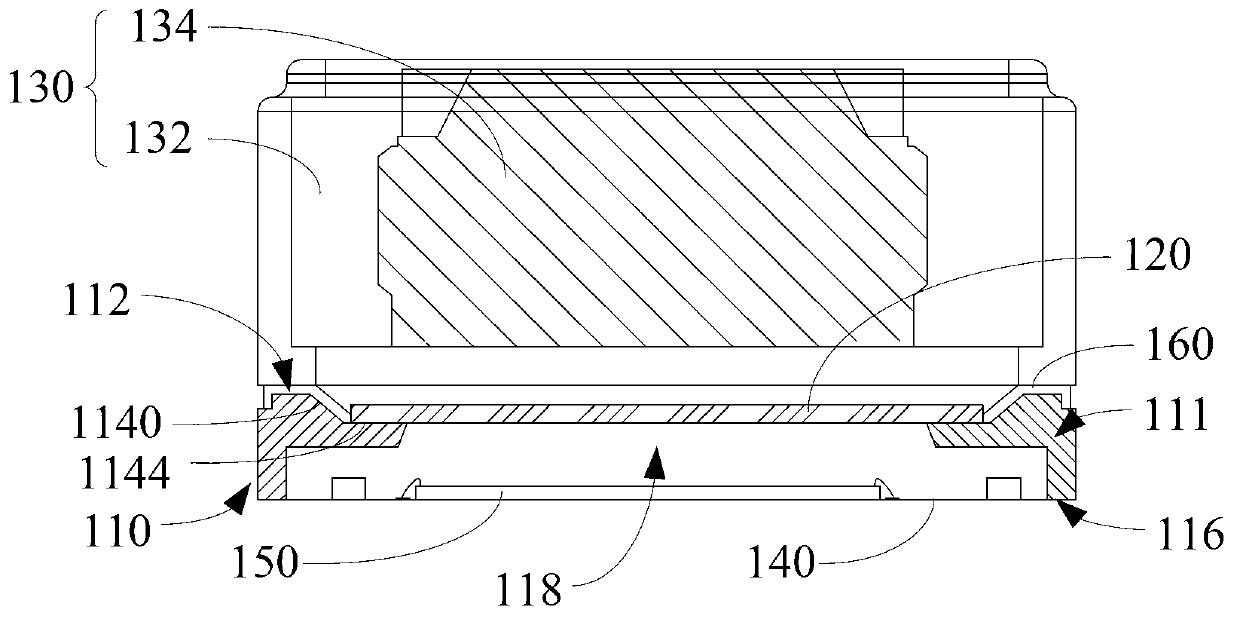

[0019] Such as figure 1 with figure 2 As shown, a bracket structure 110 includes a bracket body 111. The bracket body 111 includes a first surface 112 and a second surface 116 opposite to the first surface 112. The first surface 112 is provided with a concave for placing the filter 120. In the groove 114 , the side wall 1140 of the groove is arranged obliquely relative to the bottom surface 11...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com