Magnetic rotating drum filter

A filter and magnetic technology, used in magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of cleaning agent pollution, affecting strip cleaning quality, etc., to achieve reliable cleanliness and improve cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

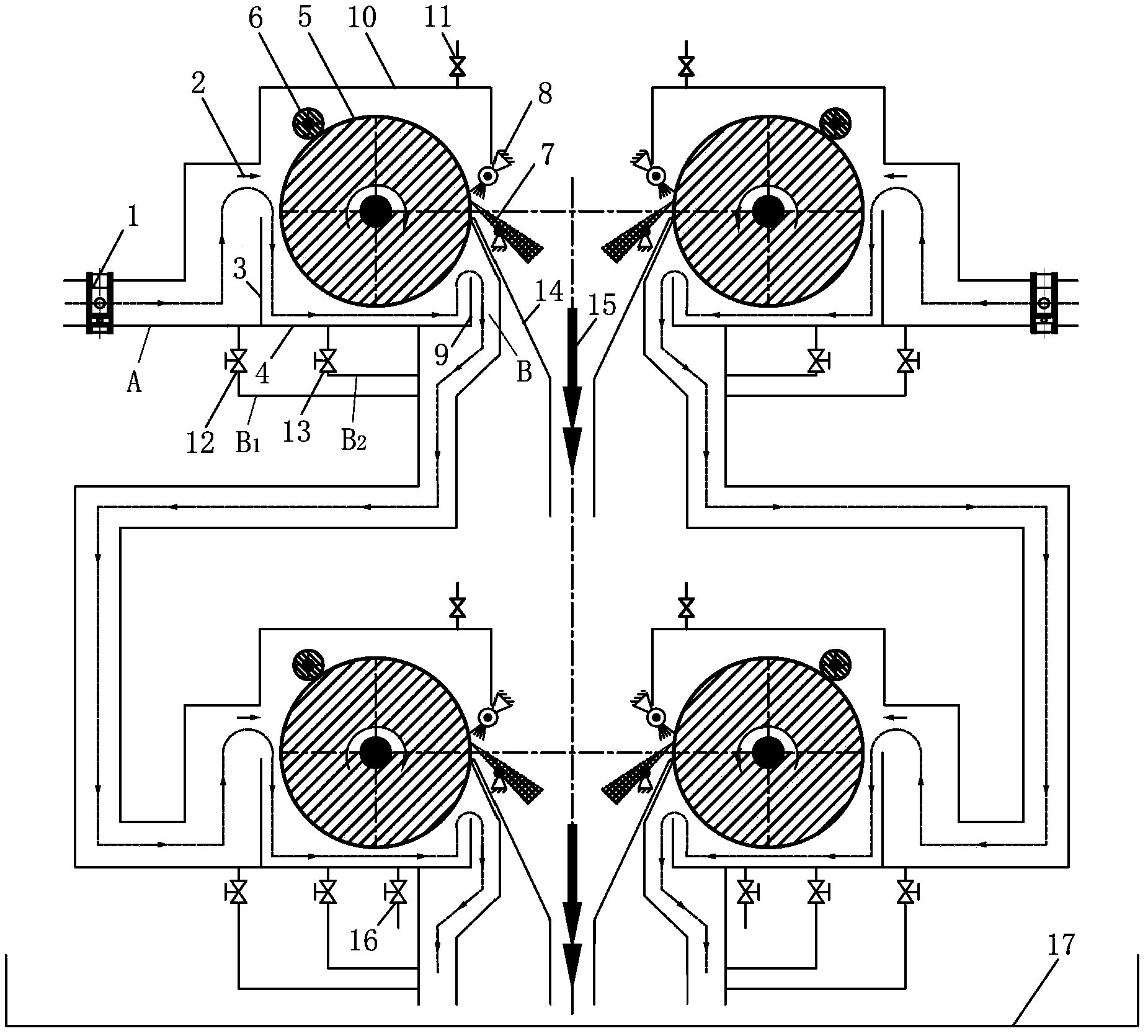

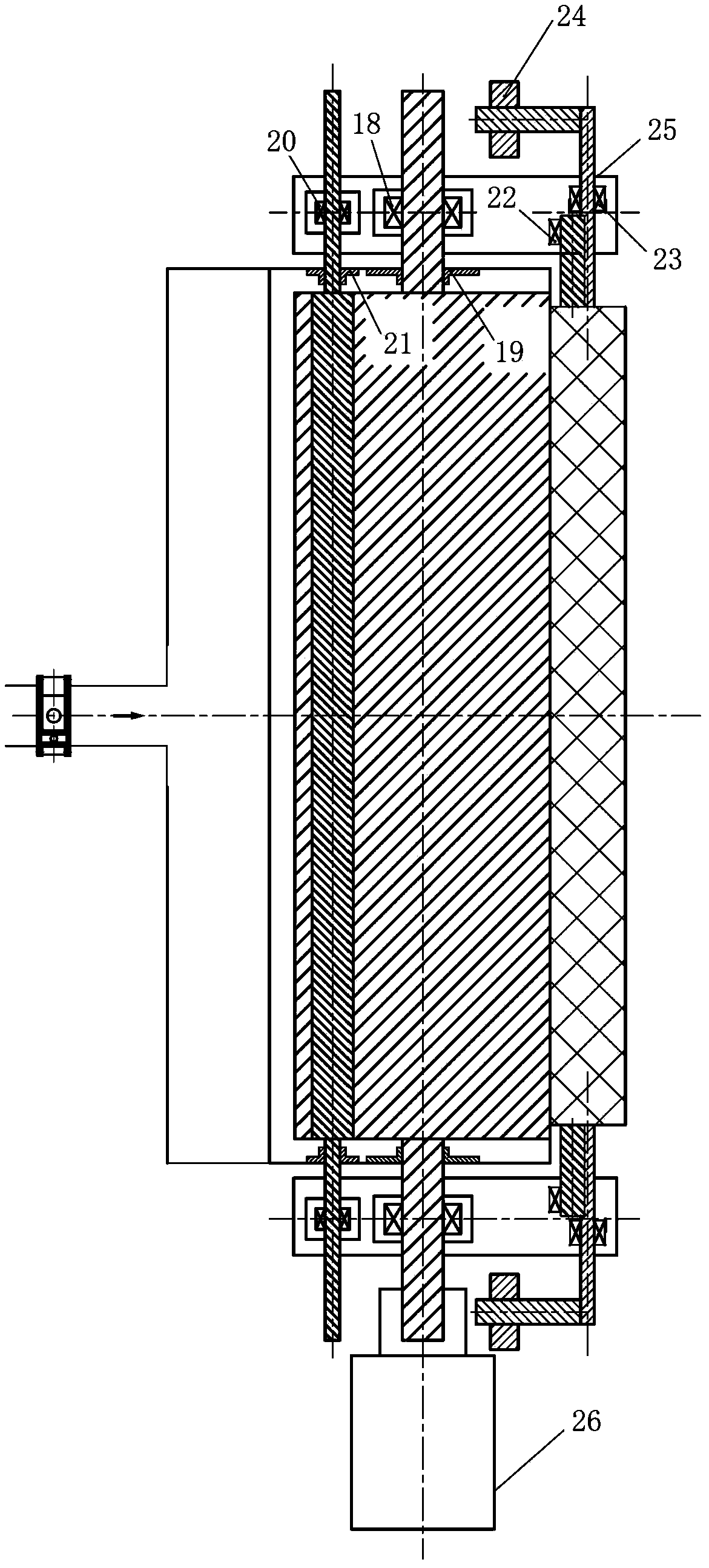

[0029] figure 1 It is a front sectional view showing the structure of the magnetic drum filter of the present invention, figure 2 It is an upper sectional view showing the magnetic drum filter of the present invention.

[0030] The magnetic drum filter of the present invention can be used alone, and can also be used in series in multiple stages, and the filtering effect can be improved when used in series. In addition, the magnetic drum filter of the present invention can also be used in parallel, and can perform two-way shunt treatment on the cleaning agent circulation system when in parallel. figure 1 The figure shows the situation that the two-stage magnetic drum filter connected in series is used in parallel again. By using the magnetic drum filter constituted in this way, the cleaning agent circulation system can be divided into two streams, and each s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com