Filtering unit of side-air intake ultra-thin draught fan

A filter unit and fan technology, which is applied in the fields of dispersed particle filtration, space heating and ventilation details, household heating, etc. The effect of saving vertical space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

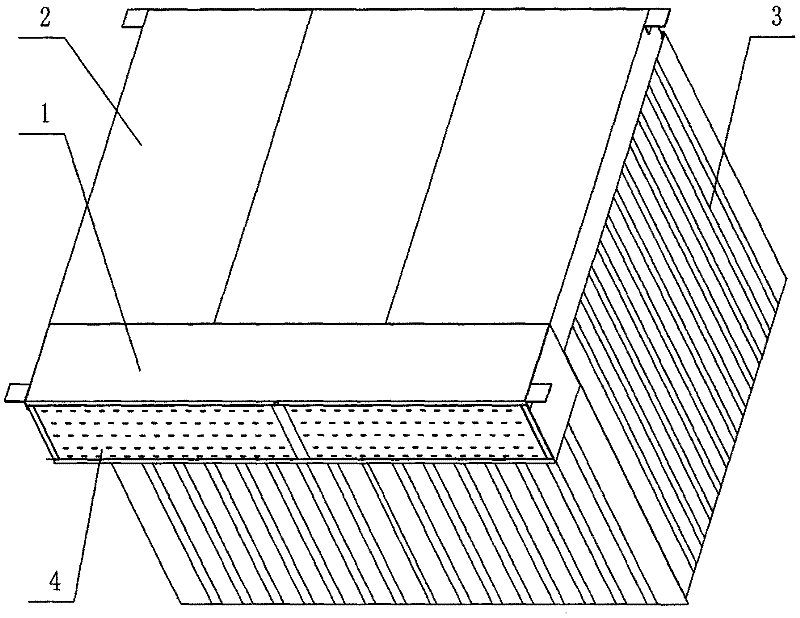

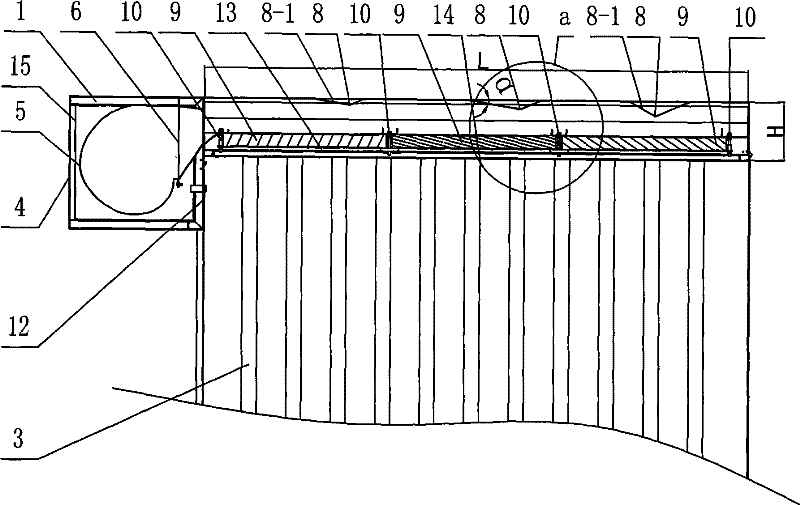

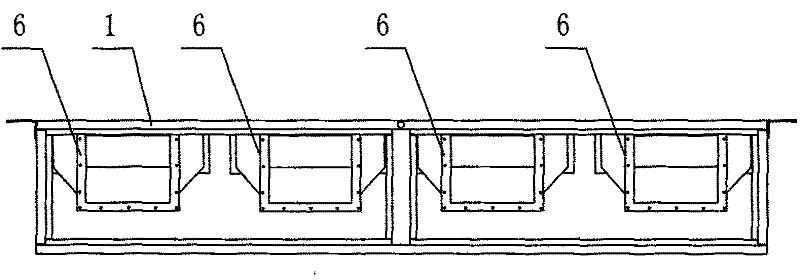

[0008] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, this embodiment includes air induction device and static pressure filtering device, and described air induction device is made up of fan box 1, multiple fans 5 and multiple transition flanges 6, and described static pressure filtering device is composed of static pressure The filter box 2, the support frame 13, a plurality of pressure equalizing baffles 8, a plurality of high-efficiency filters 9 and a plurality of filter compression mechanisms 10 are composed; the air inlet end plate 4 of the fan box 1 is a mesh plate, so The air outlet end plate 12 of the fan box 1 has a plurality of installation openings, and the plurality of fans 5 are arranged in the fan box 1 along the width direction of the fan box 1, and the outlet ends of the plurality of fans 5 pass through a plurality of transitions. The flange 6 is installed at the corresponding installation port on the air outlet end p...

specific Embodiment approach 2

[0009] Specific implementation mode two: combination Figure 7 ~ Figure 9 To illustrate this embodiment, the transition flange 6 of this embodiment is a deformed transition flange with a constant cross-sectional area, and the inlet end 6-1 to the outlet end 6-2 of the transition flange 6 are connected by a square truss 6-3, And the areas of the cross-sections of the transition flange 6 are equal. This arrangement eliminates additional wind pressure. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination Figure 5 The present embodiment is described. The lower end plate 14 of the static pressure filter box 2 of the present embodiment has a hole diameter φ of punching holes of 3 mm to 5 mm. With such setting, the diffused flow effect is good and the operation is stable. Other compositions and connections are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com