Preparation method of vanadium-titanium iron concentrate magnetized pellets for shaft furnace

A technology of vanadium-titanium-iron concentrate and pellets, which is applied in the field of preparation of vanadium-titanium-iron concentrate magnetized pellets for shaft furnaces, can solve the problems that the reduction process of blast furnaces and shaft furnaces cannot be carried out normally, and improve the desulfurization effect and equipment The effect of few and simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

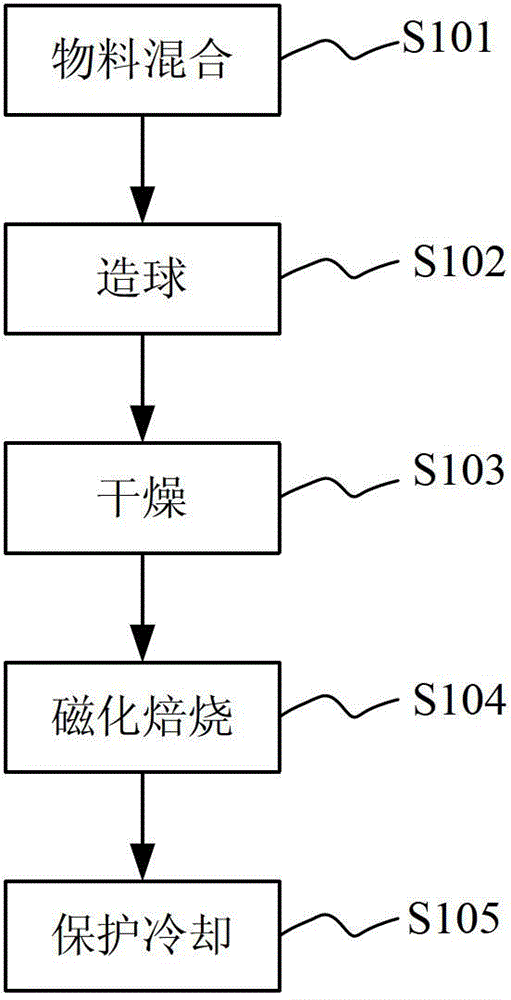

[0030] The preparation method of the vanadium-titanium-iron concentrate magnetized pellets for the shaft furnace provided by the embodiment of the present invention comprises:

[0031] Step S101: mixing materials;

[0032] Mix the vanadium-titanium-iron concentrate powder and the binder according to the following weight ratio: vanadium-titanium-iron concentrate powder: binder=100:2-6.

[0033] Step S102: making pellets;

[0034] The mixed material is pelletized to obtain raw pellets. The pelletizing equipment is a disc pelletizer. The rotation frequency of the disk pelletizer is 2936Hz, the inclination angle is 30°~45°, and the pelletizing time is 20~ After 30 minutes, the obtained pellets have a diameter of 7-20 mm and a water content of 5-8%. The particle size of the green pellets is preferably 10mm-15mm.

[0035] Step S103: drying;

[0036] The green pellets are dried, and the green pellets are dried in a blast drying oven, the drying temperature of the blast drying ove...

Embodiment 1

[0043] The vanadium-titanium iron concentrate and the binder are uniformly mixed in a weight ratio of 100:2, the vanadium-titanium iron concentrate has a particle size of -200 mesh, accounting for 55%, and the binder is bentonite. The mixture is rolled and formed into round pellets on a disc pelletizer, and the maximum radial dimension of the pellets is 9mm. The green pellets were dried in a blast drying oven at a drying temperature of 220°C and a drying time of 50 minutes. The CO content was 5%, the calcination temperature was 1000°C, and the calcination time was 100min to obtain magnetized pellets, which were cooled under nitrogen protection. After testing, the magnetic susceptibility of the obtained magnetized pellets is 0.64, the sulfur removal rate is 86%, the compressive strength is 760N, the drop strength is 5 times / ball, and the linear expansion rate is 3% in the direct reduction process of the gas-based shaft furnace.

Embodiment 2

[0045]The vanadium-titanium iron concentrate and the binder are uniformly mixed in a weight ratio of 100:3, the vanadium-titanium iron concentrate has a particle size of -200 mesh, accounting for 60%, and the binder is bentonite. The mixture is rolled and formed into round pellets on a disc pelletizer, and the maximum radial dimension of the pellets is 15mm. The green pellets were dried in a blast drying oven at a drying temperature of 180°C and a drying time of 60 minutes. The CO content was 10%, the calcination temperature was 1100°C, and the calcination time was 110min to obtain magnetized pellets, which were cooled under nitrogen protection. After testing, the magnetic susceptibility of the obtained magnetized pellets is 0.62, the sulfur removal rate is 89%, the compressive strength is 1086N, the drop strength is greater than 20 times / ball, and the linear expansion rate is 2% during the direct reduction process of the gas-based shaft furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com